Flatcar track cross arranging method

A track and flat car technology, applied in the field of flat car track crossing, can solve the problems of inconvenience, trouble and difficulty in the normal passage of flat cars, and achieve the effect of simple setting structure, low cost and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

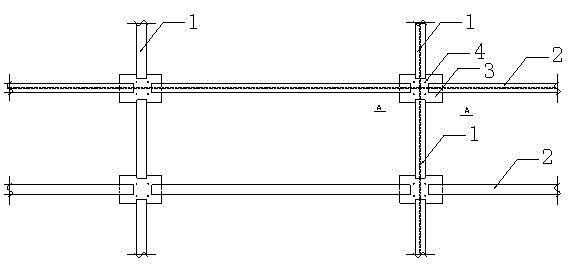

[0022] see now figure 1 and figure 2 , figure 1 It is a schematic diagram of a double-track cross structure in an embodiment of the present invention, figure 2 for figure 1 A-A sectional view in . As shown in the figure, the first track 1 and the second track 2 cross each other.

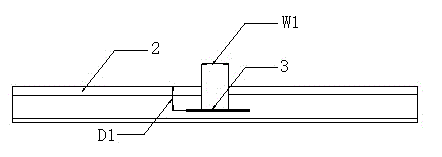

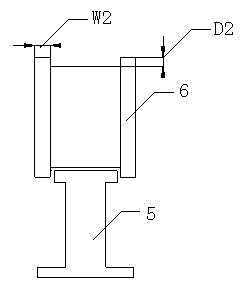

[0023] image 3 It is a structural schematic diagram of the track and the wheel of the embodiment of the present invention. The first track 1 and the second track 2 are respectively incompletely disconnected at the cross position, which is to determine the width W1 and track cutting depth D1 of the track to be cut according to the rim width W2 and rim height D2 of the flat wheel 6 respectively . It is equivalent to slotting on the track. This slot is to let the rim of the traveling wheel pass through here, and place a wear-resistant steel plate 3 under the slot. The thickness is 34mm. The length and width of the steel plate are based on the slot. The size of the steel plate 3 and the track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com