Hydraulic drill carriage drill arm moving fulcrum metamorphic mechanism

A technology of hydraulic drilling rig and metamorphic mechanism, which is applied in drilling equipment, earth-moving drilling, drilling equipment and methods, etc., can solve the problems of working angle, inconvenient transportation and folding, and the structure of drilling arm cannot meet the requirements, so as to achieve the working angle big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Now in conjunction with accompanying drawing, the present invention is described in further detail.

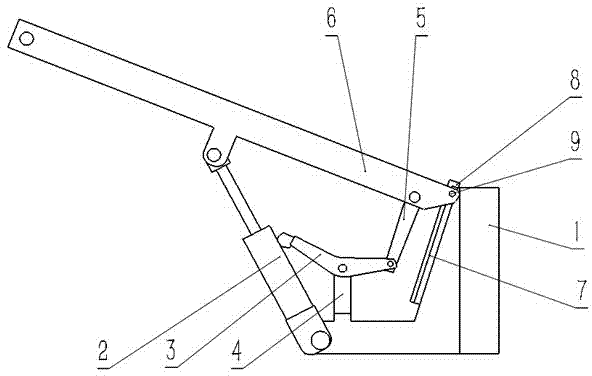

[0008] Such as figure 1 As shown, one end of the hydraulic cylinder 2 is hinged with the body 1, and the other end is hinged with the boom 6; the displacement twist rod support 4 is connected with the body 1, and the displacement twist rod 3 is hinged on the displacement twist rod support 4. The twisted rod 3 is hinged with one end of the boom connecting rod 5, and the other end of the boom connecting rod 5 is hinged with the boom 6. The boom slider 9 is installed at the tail of the boom 6, and the boom slider 9 slides on the slide rail 7. , the slide rail 7 is installed on the body 1, and the slide rail limit block 8 is installed on the top of the slide rail 7.

[0009] When the hydraulic cylinder 2 moves to a certain position, the hydraulic cylinder 2 is in contact with the displacement winch 3, and the displacement winch 3 is pushed to pull the boom connecting rod 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com