Hydraulic drill carriage drill arm adding connecting rod metamorphic mechanism

A technology of hydraulic drilling rig and metamorphic mechanism, which is applied in drilling equipment, earthwork drilling, support devices, etc., can solve the problems of large working angle and inability to fully lift the boom, and achieve the effect of large working angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Now in conjunction with accompanying drawing, the present invention is described in further detail.

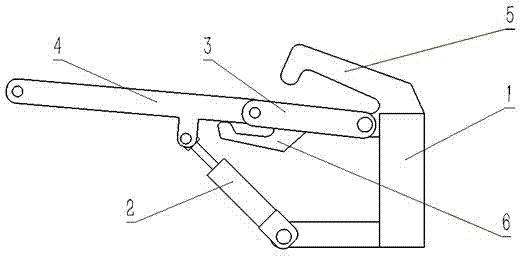

[0008] Such as figure 1 As shown, the extension arm 3 is hinged with the body 1, the main arm 4 is hinged with the extension arm 3, one end of the hydraulic cylinder 2 is hinged with the body 1, and the other end is hinged with the main arm 4, the variable cell rod 5 is installed on the body 1, the positioning rod 6 Installed on extension arm 3.

[0009] Before the transformation, the main arm 4 and the extension arm 3 are formed as a whole through the hinge point and the positioning rod 6 under the action of gravity. When the hydraulic cylinder 2 is extended, the extension arm 3 is in contact with the transformation rod 5, and the position is limited so that it cannot Continue to rise, the main arm 4 breaks away from the positioning rod 6 and continues to rise. Due to the displacement of the fulcrum of the main arm and the hinge point of the extended arm, the radius o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com