Abrasive belt wire polisher

A grinding machine and grinding mechanism technology, applied in the direction of abrasive belt grinding machines, grinding machines, grinding/polishing equipment, etc., can solve the problems of low manual grinding efficiency, poor grinding surface quality of grinding wheels, etc., and achieve small deformation and work wrap angle Large and rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

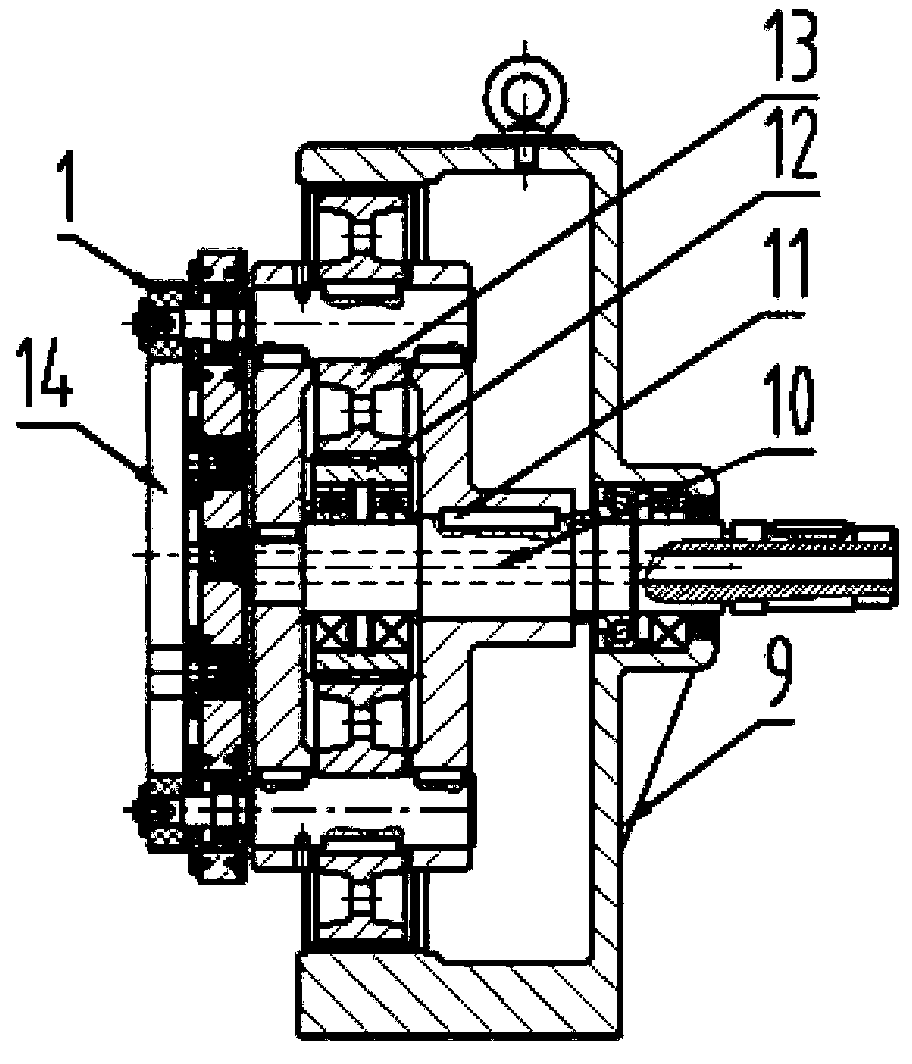

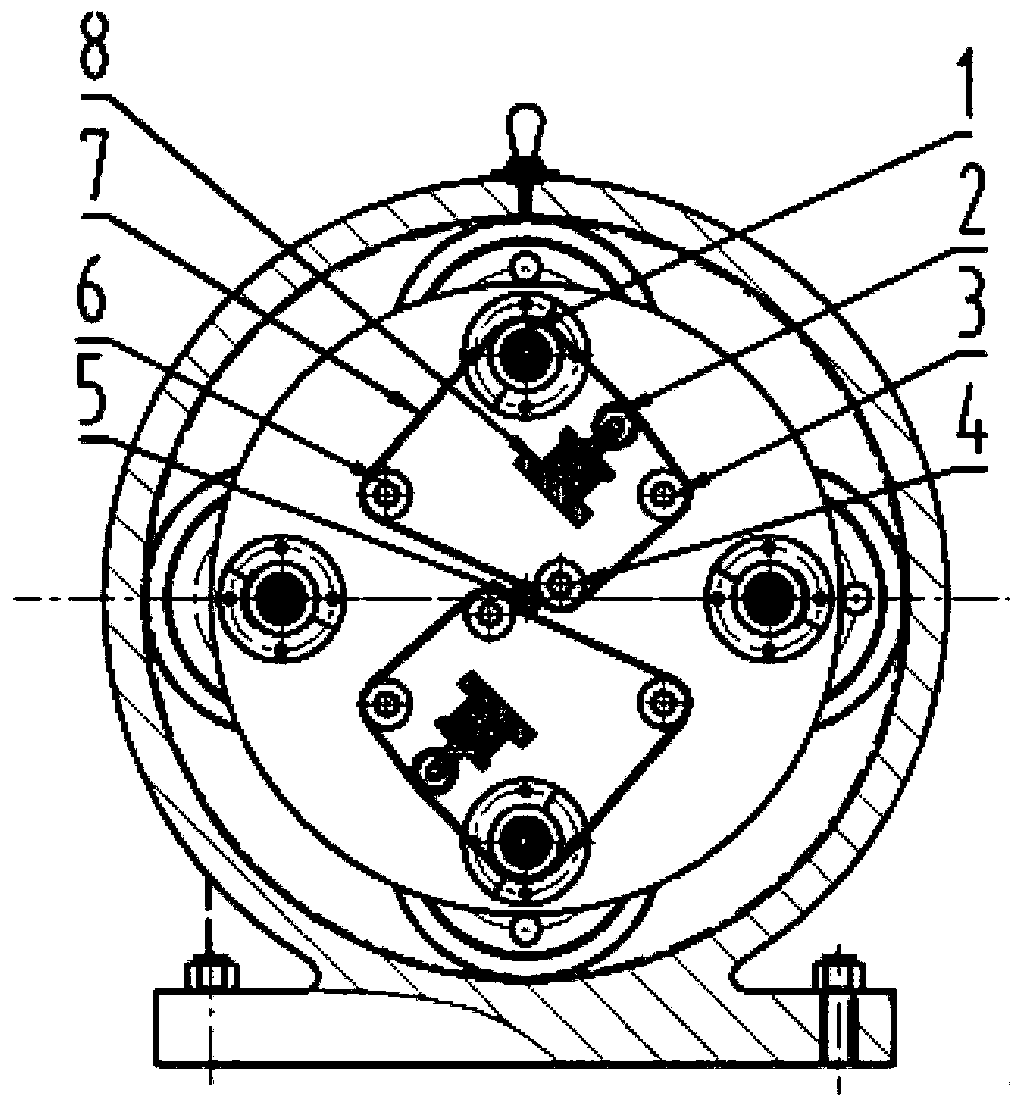

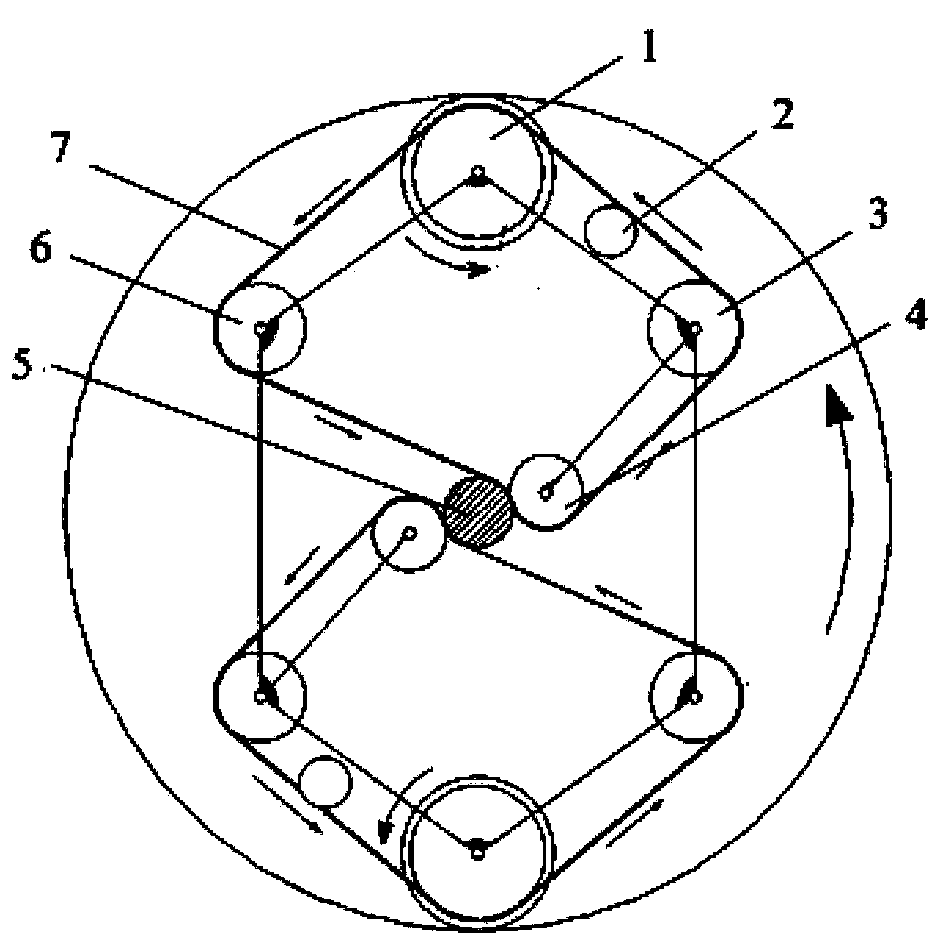

[0023] A kind of abrasive belt wire grinding machine, see figure 1 , figure 2 and image 3 , including a grinding mechanism 14 driven by a motor 15, the grinding mechanism 14 includes two abrasive belts 7 and is symmetrically tensioned on the two drive wheels 1 by the tensioning mechanism 8, the idler A3, the idler B6 and the contact wheel 4 respectively, The tensioning mechanism 8 includes a tensioning wheel 2 , and the driving wheel 1 is connected with the planetary gear train through a planetary wheel 13 . Planetary gear 13, hollow shaft 10, sun gear 12 and planet carrier 11 constitute planetary gear train and are connected with motor 15 by hollow shaft 10, and sun gear 12 can rotate around hollow shaft 10, and planetary gear train is arranged on the frame 9, and wire The material 5 passes through the hollow shaft 10 and moves axially. The hollow shaft 10 drives the planetary gear 13 to rotate around the sun gear 12 through the planet carrier 11, and the planetary gear 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com