A static screen structure of polishing machine that can effectively reduce the broken rice rate

A technology of polishing machine and broken rice rate, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of increasing the working angle, increasing the number of cylinders, increasing the number of abrasions, etc., to increase the number of cylinders and increase the number of abrasions , The effect of reducing the rate of broken rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

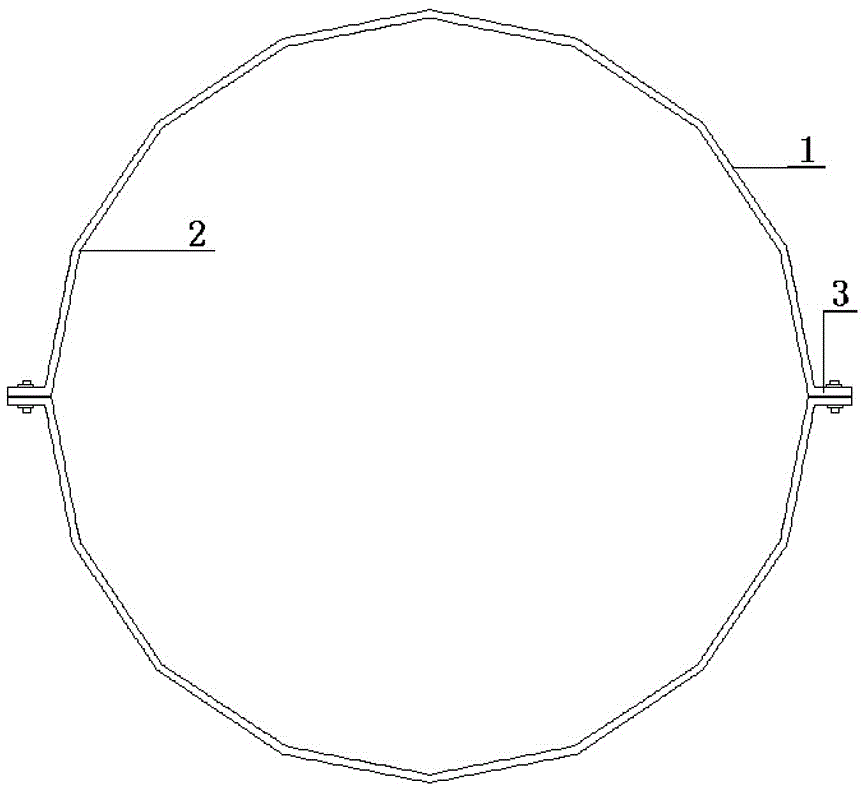

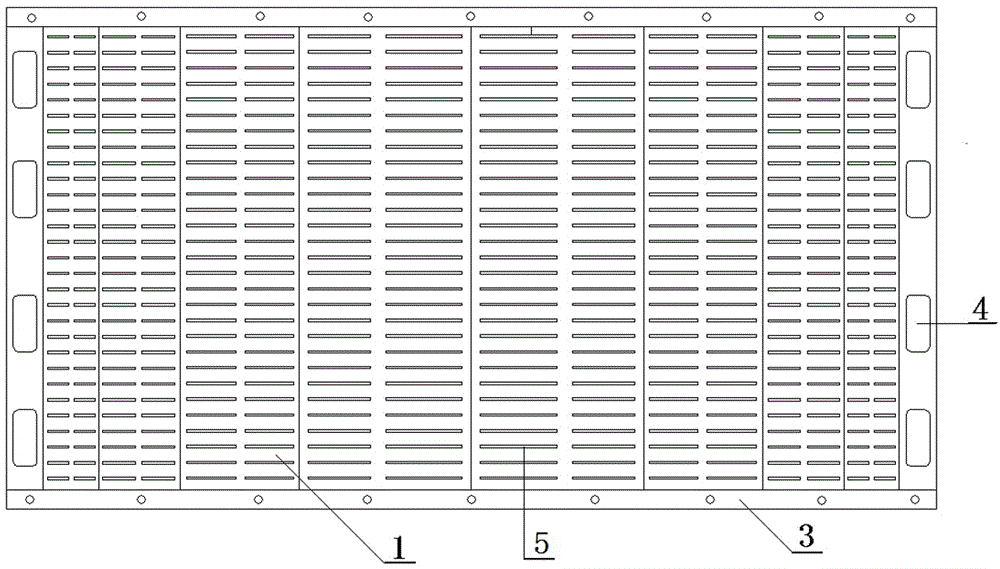

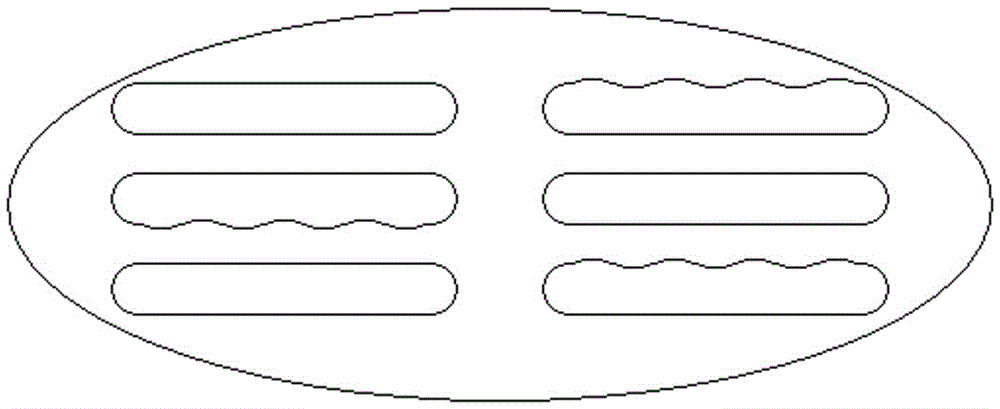

[0011] Such as figure 1 As shown, the present invention relates to a polishing screen surface 1 of a polishing machine. The polishing screen surface 1 is a split structure, which is combined to form a hollow cylinder with a polygonal mesh surface, and the working angle 2 between the cylinder surfaces is 120-170°.

[0012] The polished sieve surface 1 is a 10-20-hedron hollow cylinder structure.

[0013] The polished screen surface 1 is a mesh surface hollow cylinder structure of 12-16 faces.

[0014] The working angle 2 between the cylinders is a broken line angle, and its angle is 140-160°.

[0015] The working angle 2 between the cylinders is a circular arc transition angle, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com