Variable-stiffness energy-dissipating joints for pipe pile heads and caps

A variable stiffness, energy-consuming technology, applied in sheet pile walls, protection devices, buildings, etc., can solve problems such as difficult detection and repair of nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

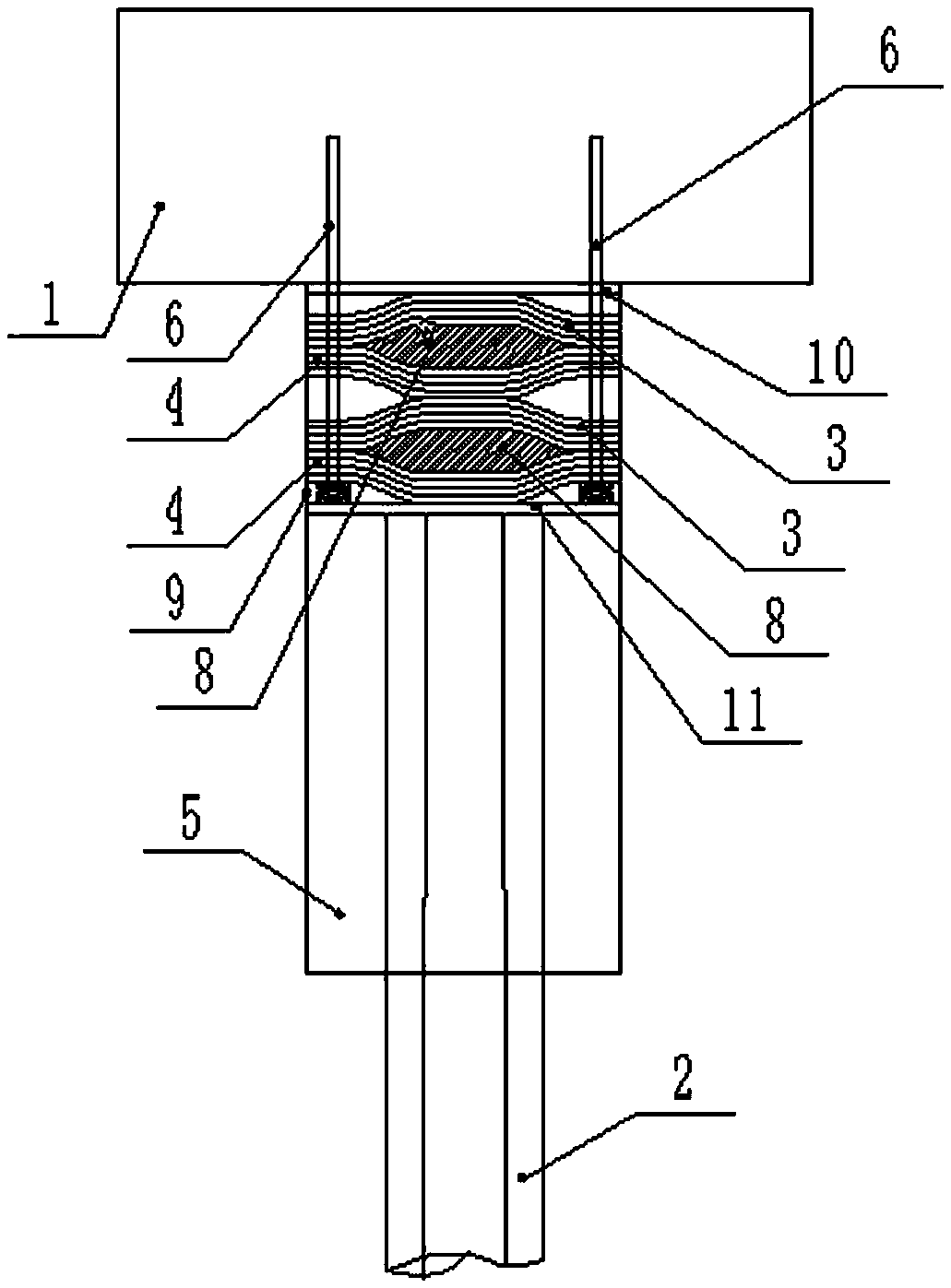

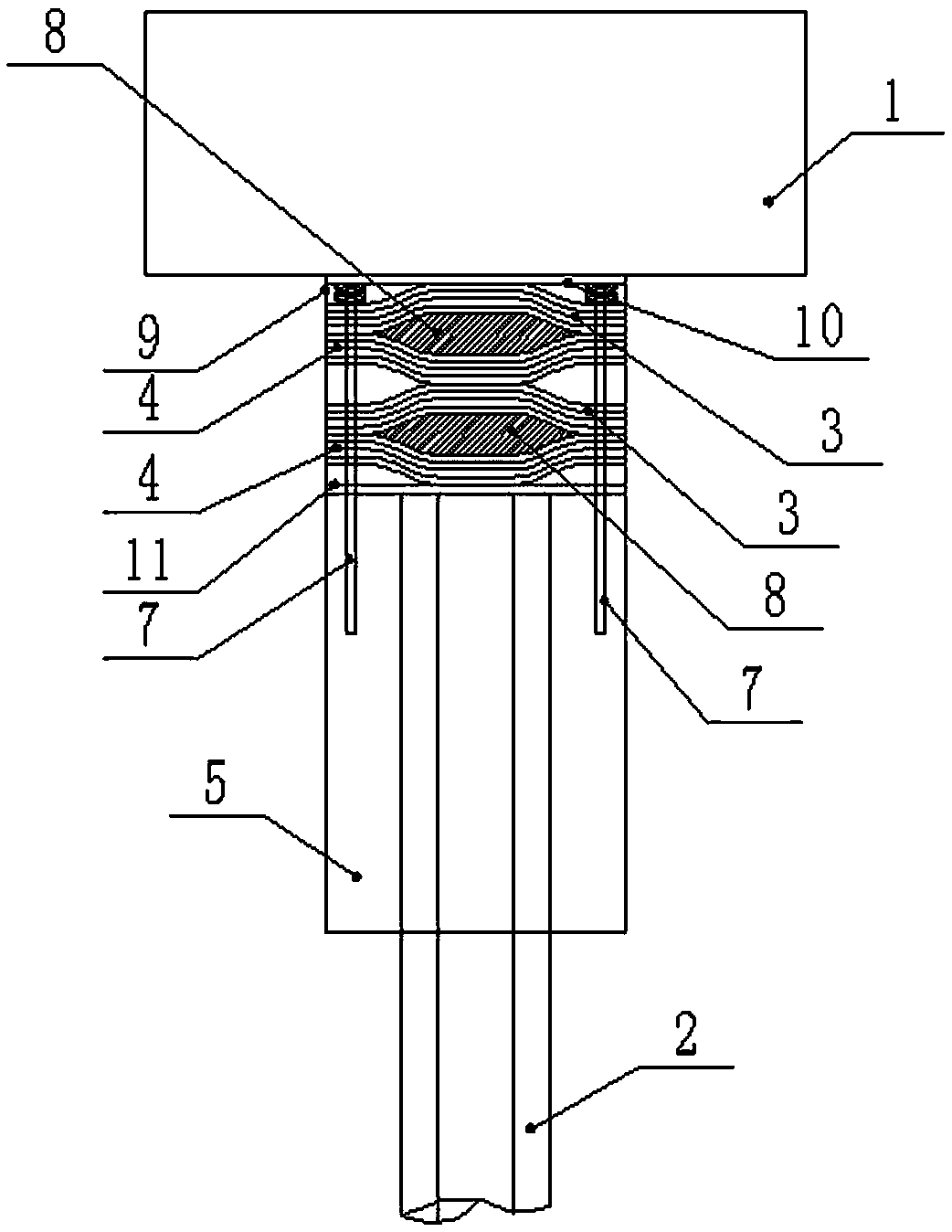

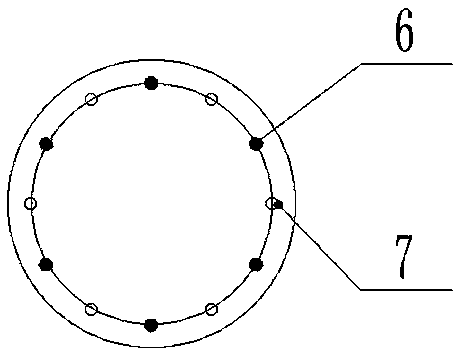

[0015] The variable stiffness energy-dissipating node used for connecting the pile head of the pipe pile with the cap, including two sets of circular disc spring structures with the same structure between the cap 1 and the pile head of the pipe pile 2, installed on the upper set of circular springs The upper steel plate 10 between the disc spring structure and the cap 1 is installed on the lower steel plate 11 between the disc spring structure below and the pile head of the pipe pile 2, and the cover is arranged on the outer side of the upper steel plate 10 and the lower steel plate 11. The flexible outer packaging shell 9, the concrete expansion head 5 poured at the pile head of the pipe pile 2, a number of caps connecting anchor bolts 6 and a number of pile head connecting anchor bolts 7,

[0016] Each set of disc spring structures is composed of an upper disc spring set 3 and a lower disc spring set 4 that are superimposed on each other by several disc-shaped disc springs, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com