Anti-slip fixed fitting

A technology for fixing hardware and anti-vibration hammers, which is applied in the field of hardware, can solve problems such as the sliding of anti-vibration hammers, achieve the effects of reducing risks, reducing high-altitude liveline work, and ensuring the safety of people and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

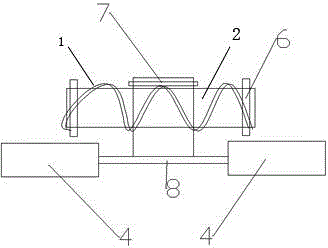

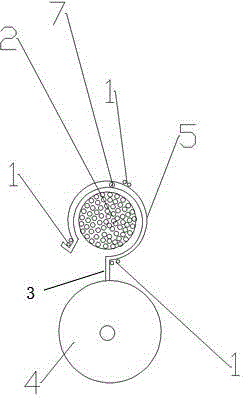

[0016] Such as Figure 1-2 As shown, it includes the anti-vibration hammer 4, the anti-vibration hammer connecting rod 8 and the buckle 5, the two ends of the anti-vibration hammer connecting rod 8 are respectively connected to the anti-vibration hammer 4, the anti-vibration hammer connecting rod 8 is connected to the buckle 5 through the clamp plate 3, and the buckle 5 is Split-type pipe collar, the arc of the buckle matches the wire, and there is a rotating shaft 7 between the inner surface of the buckle and the wire. The two ends of silk are fixed by steel hoop 6.

[0017] The open-close pipe clamp clamps the wire by closing. When the shock absorber is installed, the skein wire is wound along the outer surface of the buckle and extends out of the two ends of the buckle. It can prevent the anti-vibration hammer from sliding without wasting materials. The two ends of the twisted wire are fixed by steel hoops 6 to prevent the twisted wire from bouncing, thereby preventing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com