Colored low polarizing film, colored low polarizing plate and lens, and their manufacturing method

A polarizing lens and polarizing film technology, which is applied in the direction of optical filters, optics, optical components, etc., can solve problems such as uneven thickness, damage to appearance, and large photoelastic constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 5

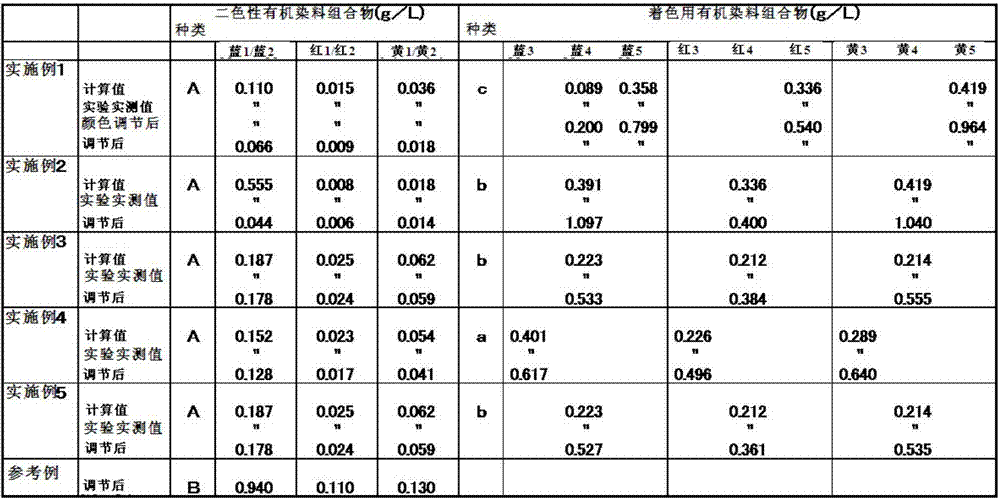

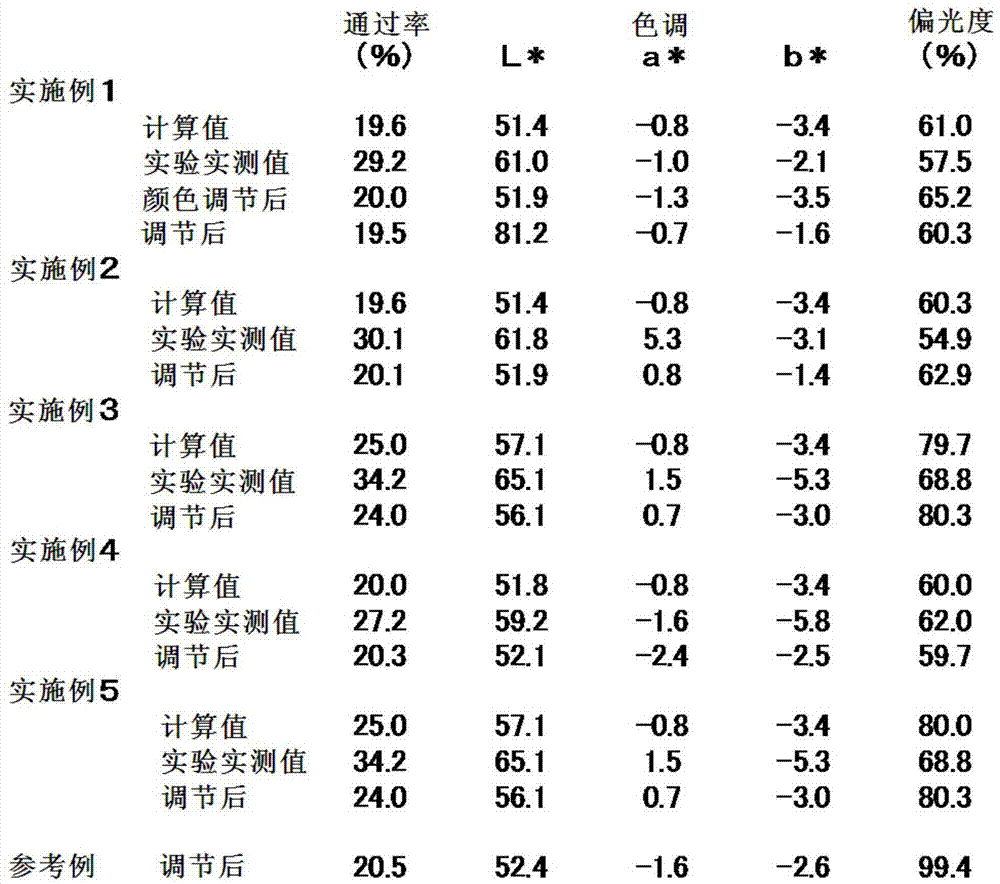

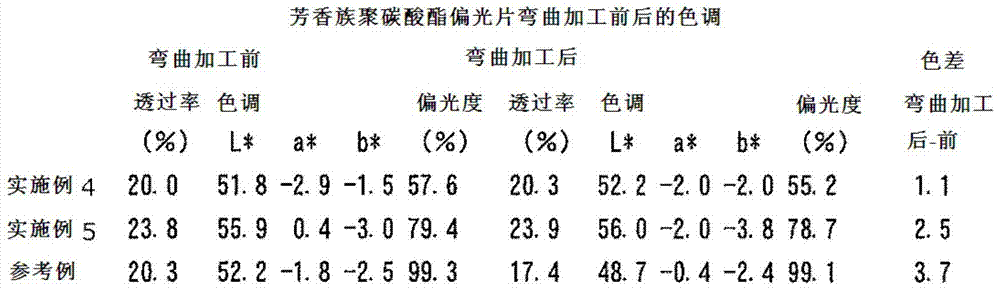

[0376] Examples 1 to 5 and Reference Examples

[0377] (1) Dichroic organic dye composition

[0378] Dichroic dye composition A:

[0379] Blue 1: C.I.Direct Blue 237(19.9), Red 1: C.I.Direct Red 81(22.0),

[0380] Yellow 1: C.I.Direct Orange 39 (23.6)

[0381] Dichroic dye composition B:

[0382] Blue 2: C.I.Direct Blue 78 (9.2), Red 2: C.I.Direct Red 254 (10.9),

[0383]Yellow 2: C.I.Direct Yellow 12 (9.0)

[0384] (2) Organic dye composition for coloring

[0385] Organic dye composition a for coloring:

[0386] Blue 3: Kayacion Blue CF-BL(1.3),

[0387] Red 3: Novacron Red C-2G (1.4), Yellow 3: C.I Reactive Yellow 145 (2.6)

[0388] Organic dye composition b for coloring:

[0389] Blue 4: C.I.Direct Blue 86(1.7),

[0390] Red 4: C.I.Direct Red 225 (2.6), Yellow 4: C.I Mordant Yellow 8 (1.7)

[0391] Organic dye composition c for coloring:

[0392] Blue 4: C.I.Direct Blue 86(1.7), Blue 5: C.I.Direct Blue 108(1.6),

[0393] Red 5: C.I.Direct Red 227(1.6), Yellow 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refraction | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com