A returnable fully flexible wrench for narrow operating space and its realization method

A technology of operation space and realization method, applied in the direction of wrench, screwdriver, manufacturing tools, etc., can solve the problem of low work efficiency and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

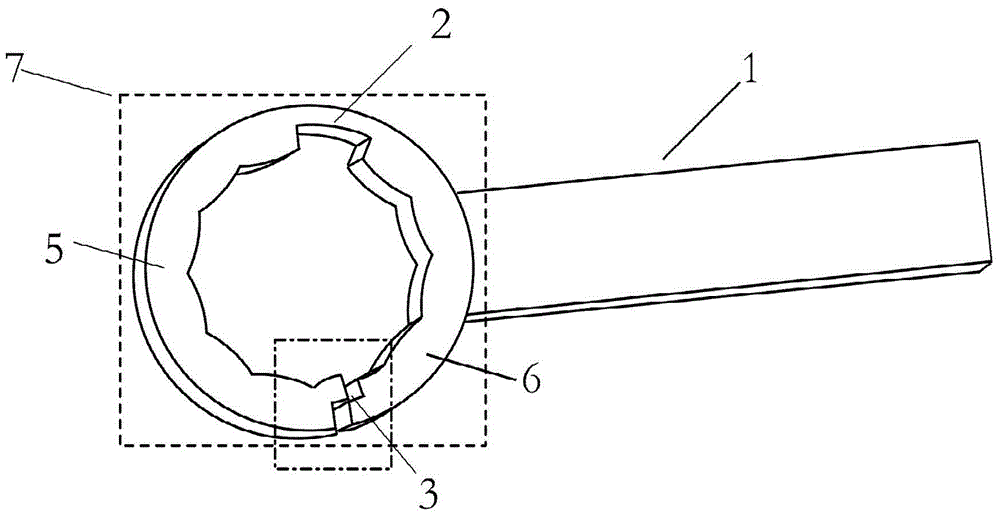

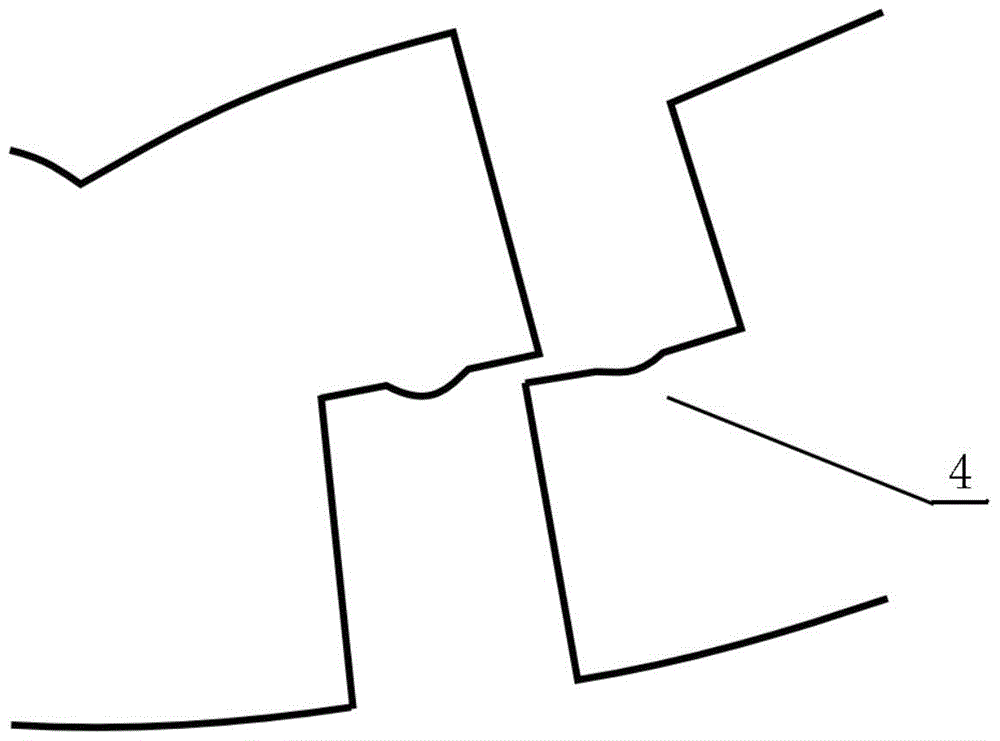

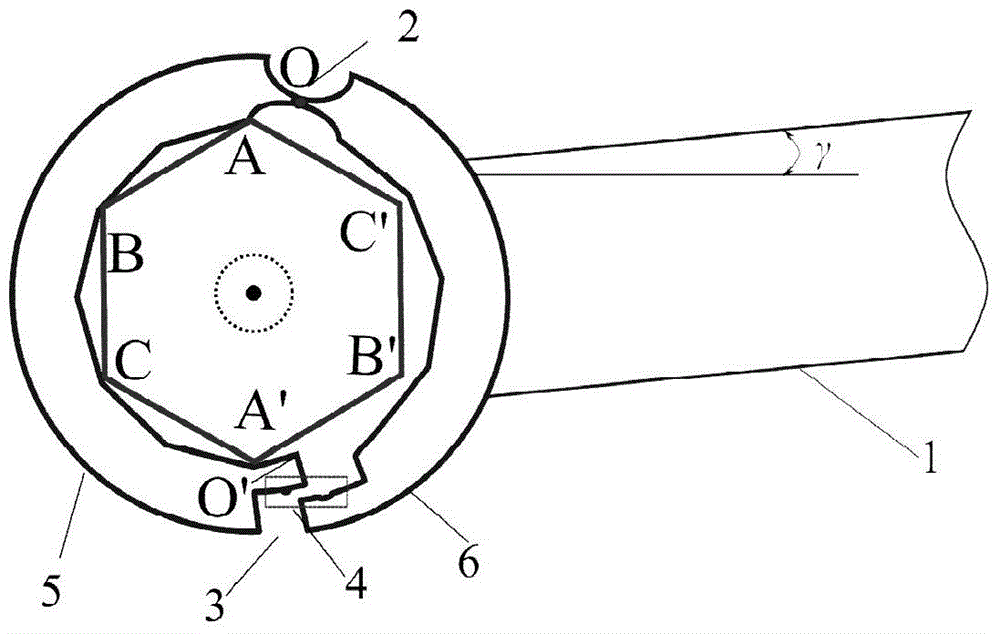

[0022] Since the threaded fastener is a symmetrical structure, the matching relationship between the wrench and the threaded fastener changes periodically, and a cycle is used to describe it.

[0023] Such as Figure 1A and Figure 1B As shown, the returnable fully flexible wrench used in a narrow operating space includes a handle 1 and a wrench head 7, and the handle 1 and the wrench head 7 are connected as one; wherein the wrench head 7 is divided into two parts by the opening 3 and the flexible hinge 2, and one part is The superior arc part 5 of the wrench head, the other part is the inferior arc part 6 of the wrench head, one end of the superior arc part 5 of the wrench head is connected to the inferior arc part 6 of the wrench head through the opening 3, and the other end of the superior arc part 5 of the wrench head is formed by a flexible The hinge 2 connects the inferior arc portion 6 of the wrench head.

[0024] The inner ring of the wrench head 7 is composed of a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com