A wiper connector and its matched wiper arm and its assembly method

A technology for connecting parts and wiper arms, applied in the field of wiper connecting parts, wiper arms and their assembly, can solve problems such as wiper blade prolapse, customer dissatisfaction, and inability to completely eliminate gaps, so as to avoid prolapse and ensure reliable clamping. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the following, with reference to the accompanying drawings and preferred embodiments, the specific implementation, features and functions of a wiper connector, a matched wiper arm and its assembly method according to the present invention will be described in detail as follows.

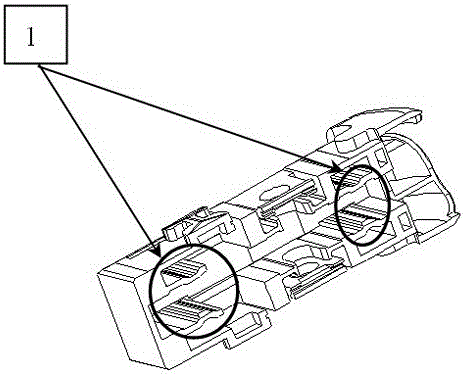

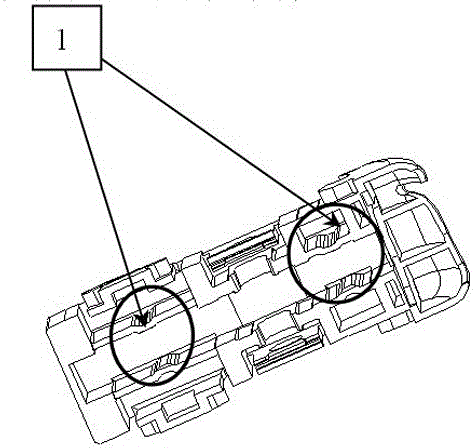

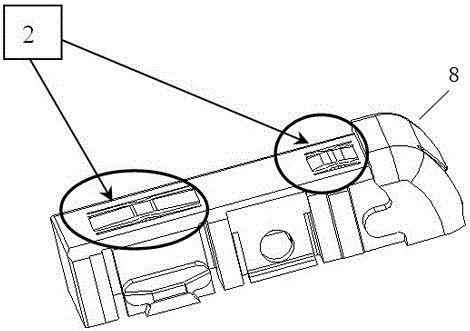

[0038] see Figure 1-14 , a wiper connector, comprising a connector body 8 and a metal connector 9, the metal connector 9 is connected to a bracket 10, and the outer side of the vertical vertical wall in the middle of the metal connector 9 is matched with a strip-shaped groove in the inner cavity of the connector; The inner cavity of the connector main body 8 is provided with an elastic structure A1, which is set as a two-sided connection structure or a cantilever structure. The elastic structure A1 is 0.15-0.35mm higher than the inner cavity plane, and the vertical structure A1 is in the middle of the metal connector 9. The purpose of matching the two outer sides of the vertical wall is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com