Color management method and device for laminated printed products

A technology of color management and printed matter, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of waste of printing machine capacity, poor effect, and difficulty in mass production of printing, and achieve high stability and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

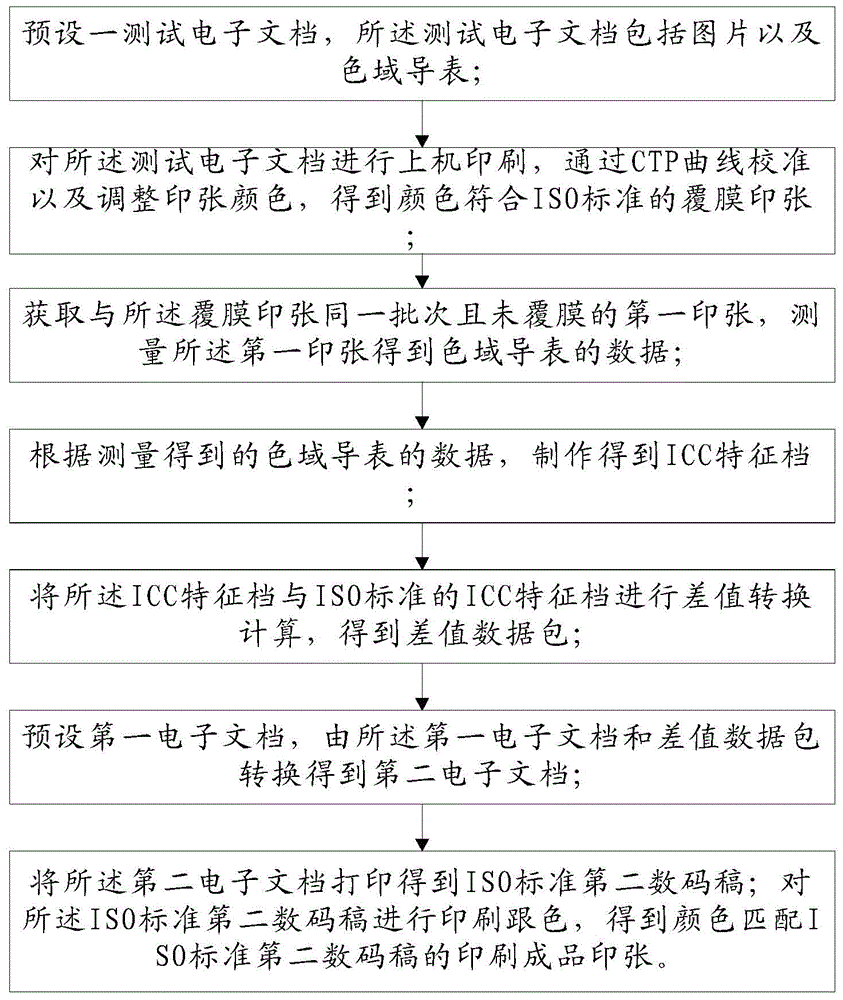

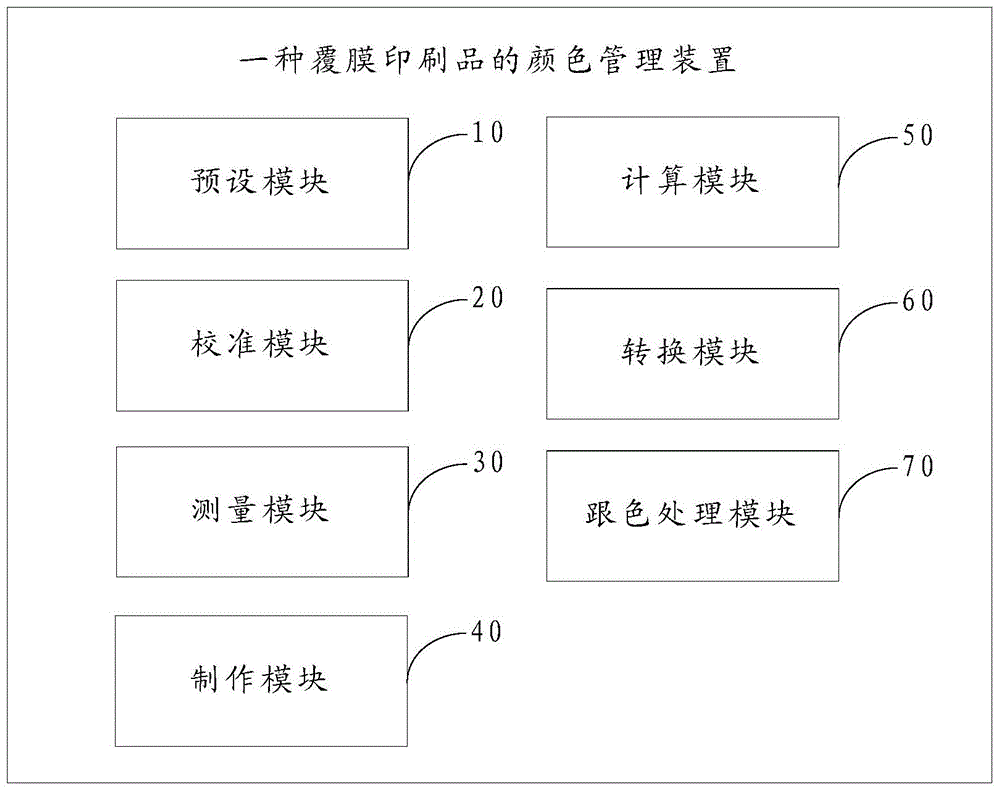

Method used

Image

Examples

Embodiment 1

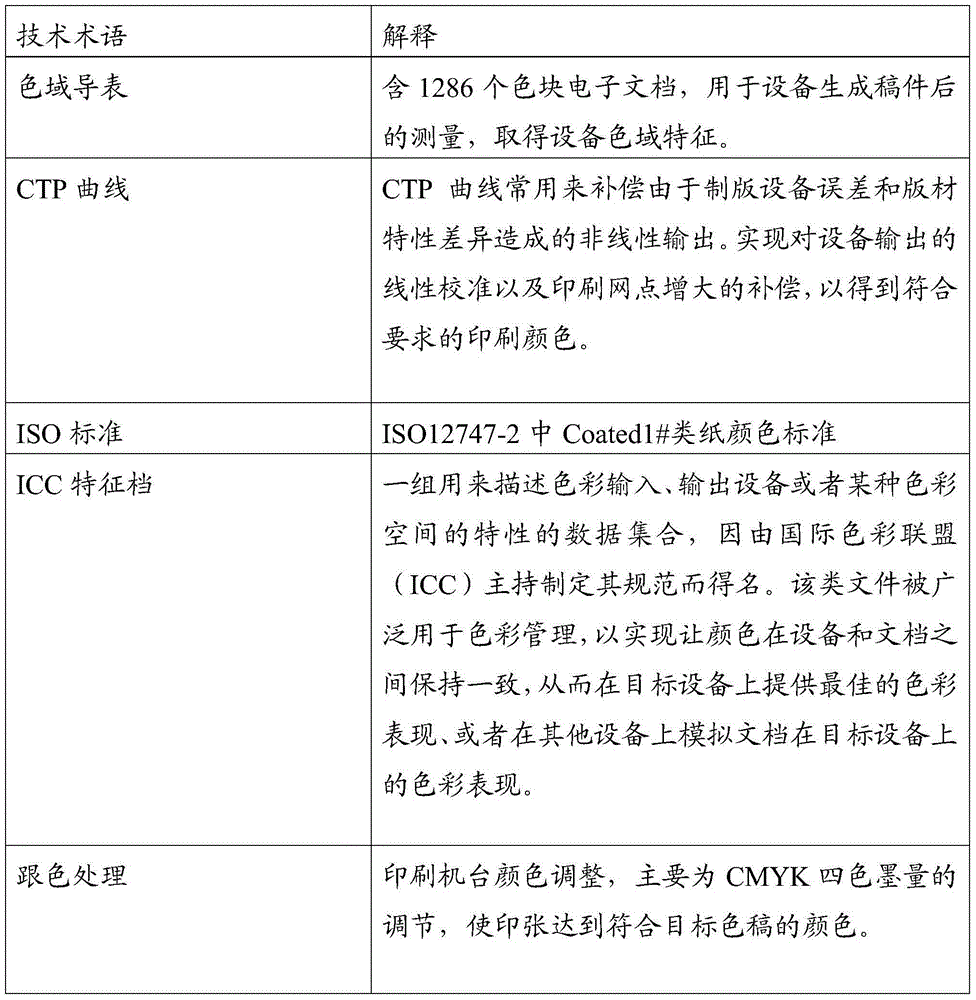

[0068] 1. Measurement of color gamut guide table

[0069] After the electronic document is printed, when the film is produced, the color difference before and after the film is relatively large. Print electronic documents including pictures and IT8 color gamut guide table through the machine, print several copies (usually 100 copies), calibrate the CTP curve and adjust the color of the printed sheet through the G7 method, so that the color of one of the several copies after lamination matches ISO standard digital manuscript (at this time the main data of the color gamut guide table conforms to the ISO standard), take several uncoated sheets at this time, and use the X-Rite series of automatic measuring instruments, such as Eye-one iSis to conduct the color gamut guide table Data measurement to get the data of the current color gamut guide table.

[0070] What needs to be explained is:

[0071] 1) The color of the coated printed sheet matches the ISO standard digital draft, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com