Patents

Literature

83 results about "ICC profile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

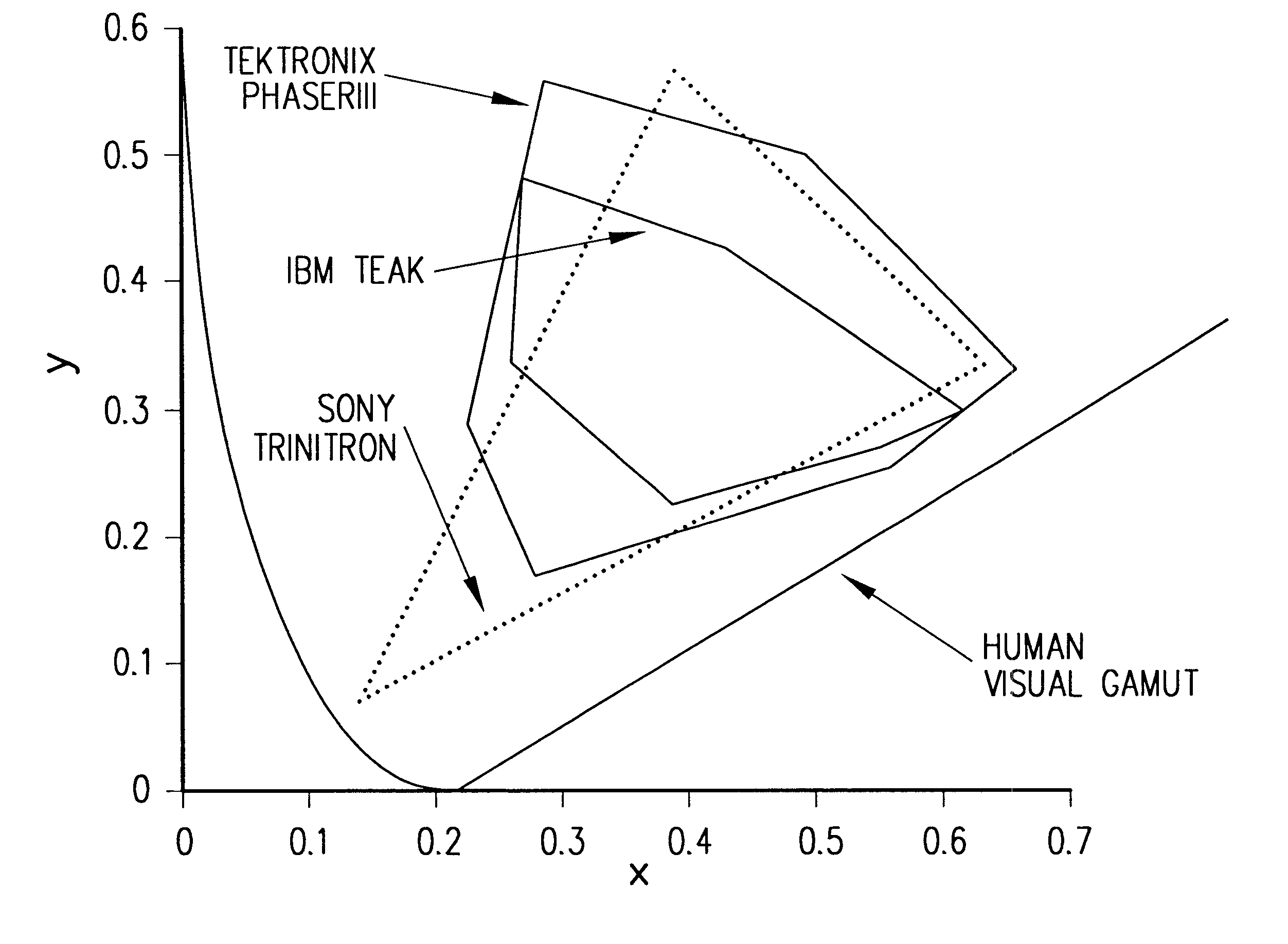

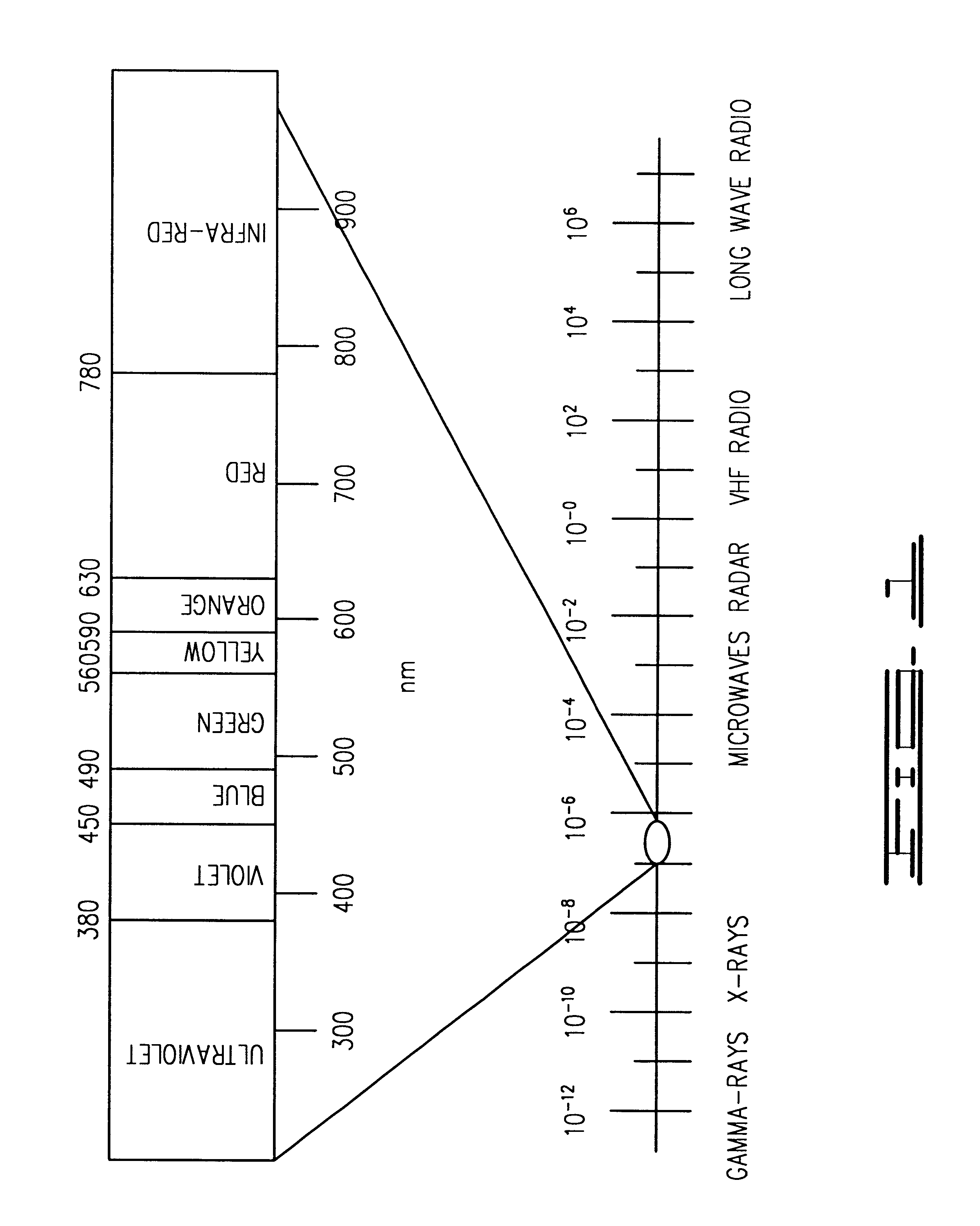

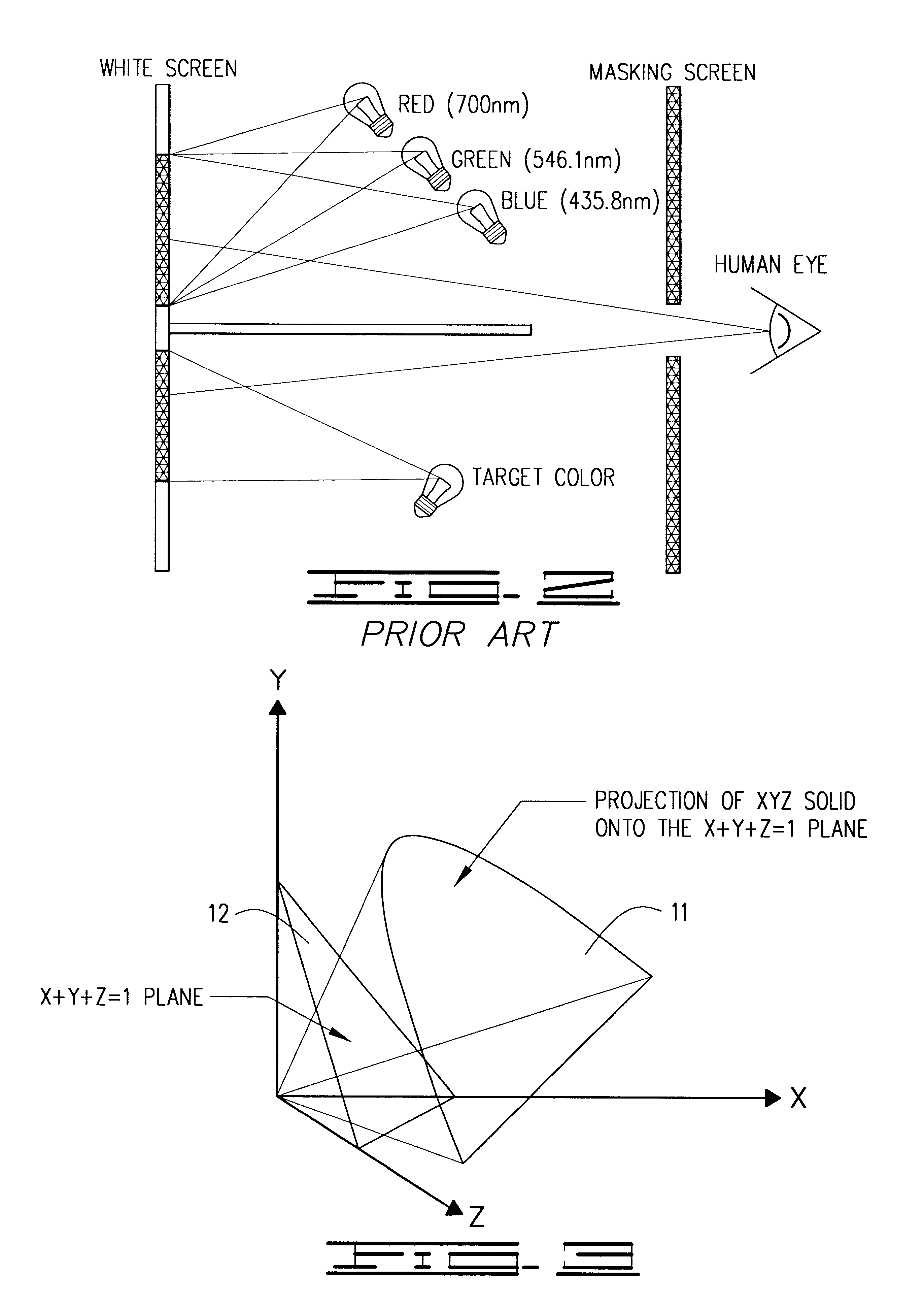

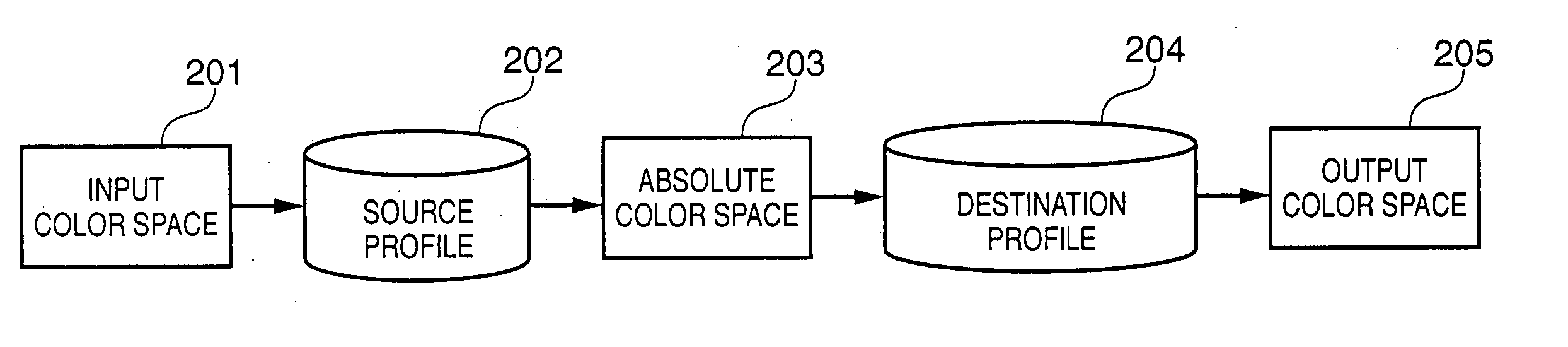

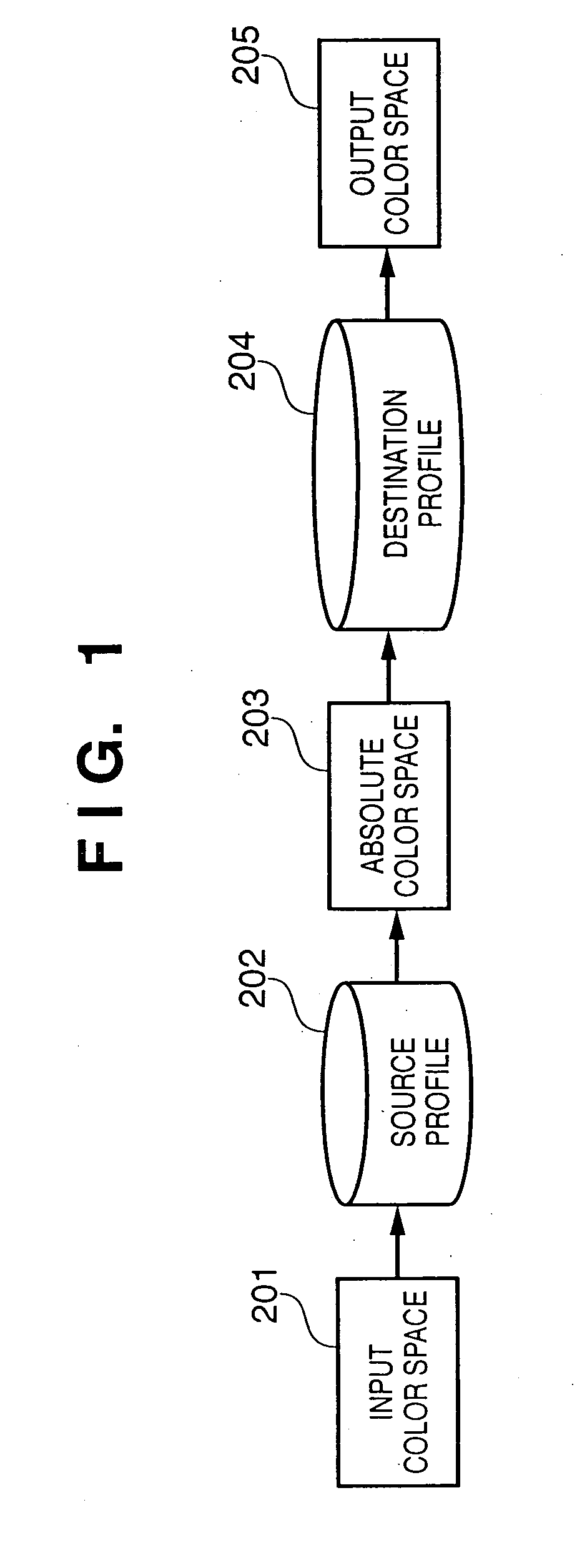

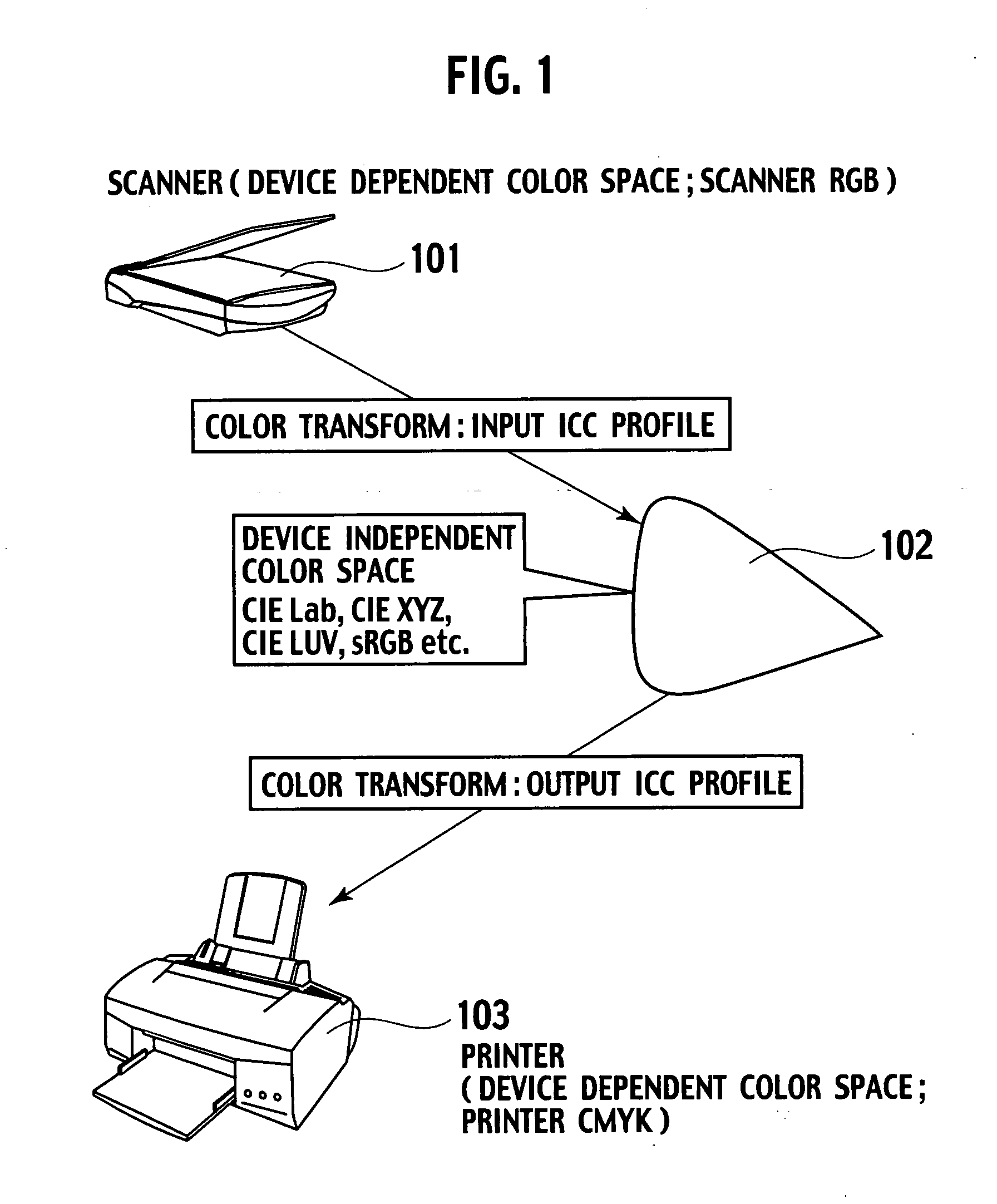

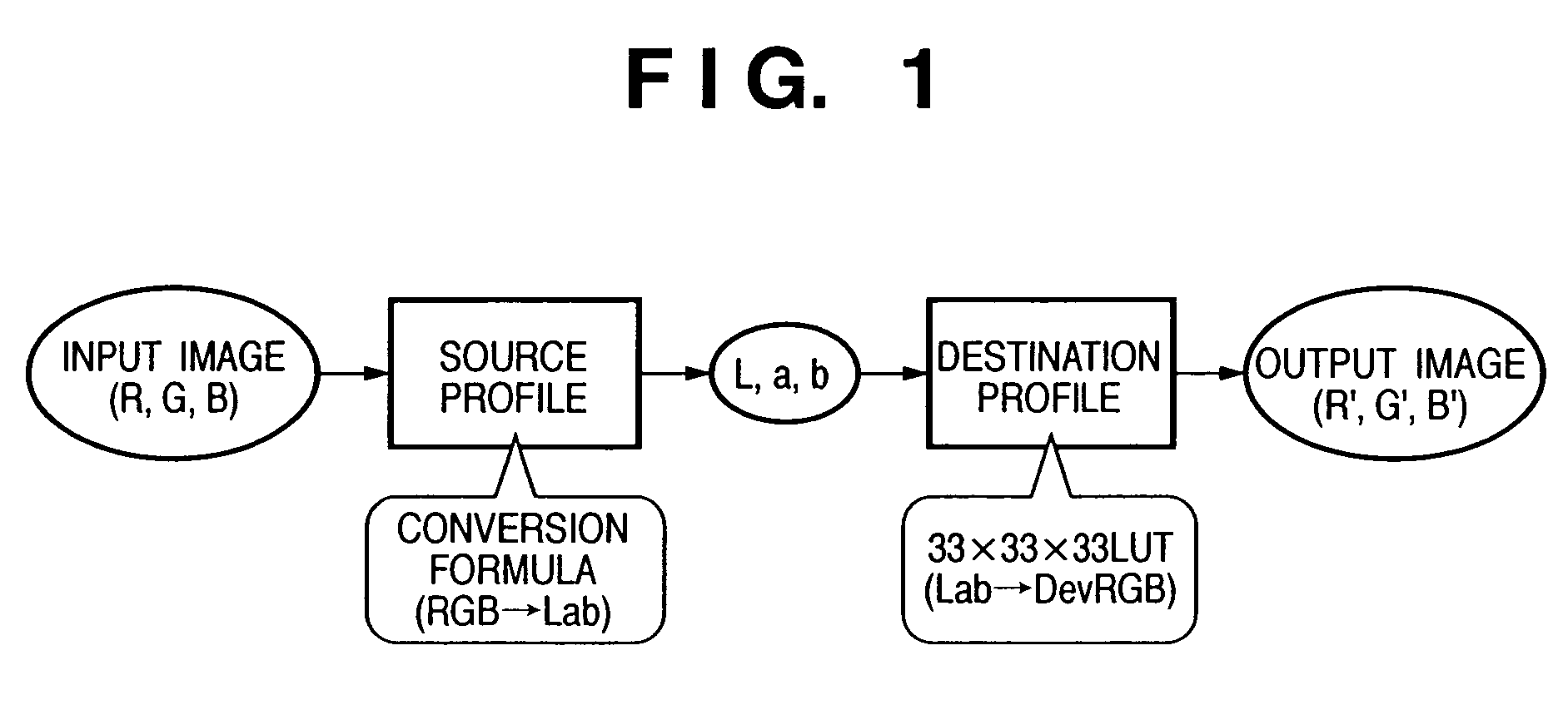

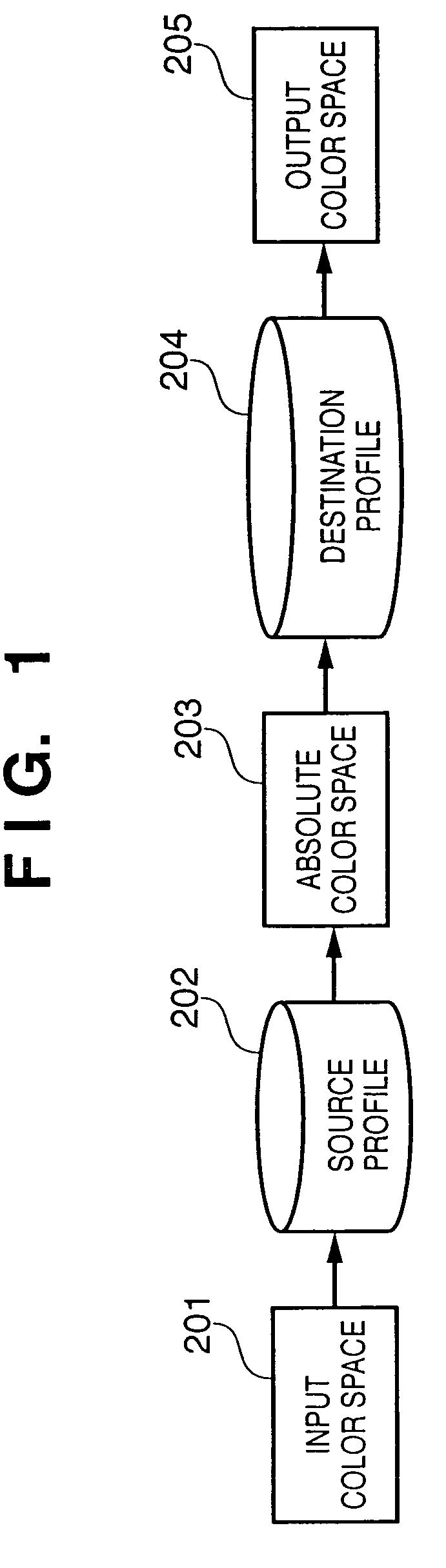

In color management, an ICC profile is a set of data that characterizes a color input or output device, or a color space, according to standards promulgated by the International Color Consortium (ICC). Profiles describe the color attributes of a particular device or viewing requirement by defining a mapping between the device source or target color space and a profile connection space (PCS). This PCS is either CIELAB (L*a*b*) or CIEXYZ. Mappings may be specified using tables, to which interpolation is applied, or through a series of parameters for transformations.

Color printer characterization using optimization theory and neural networks

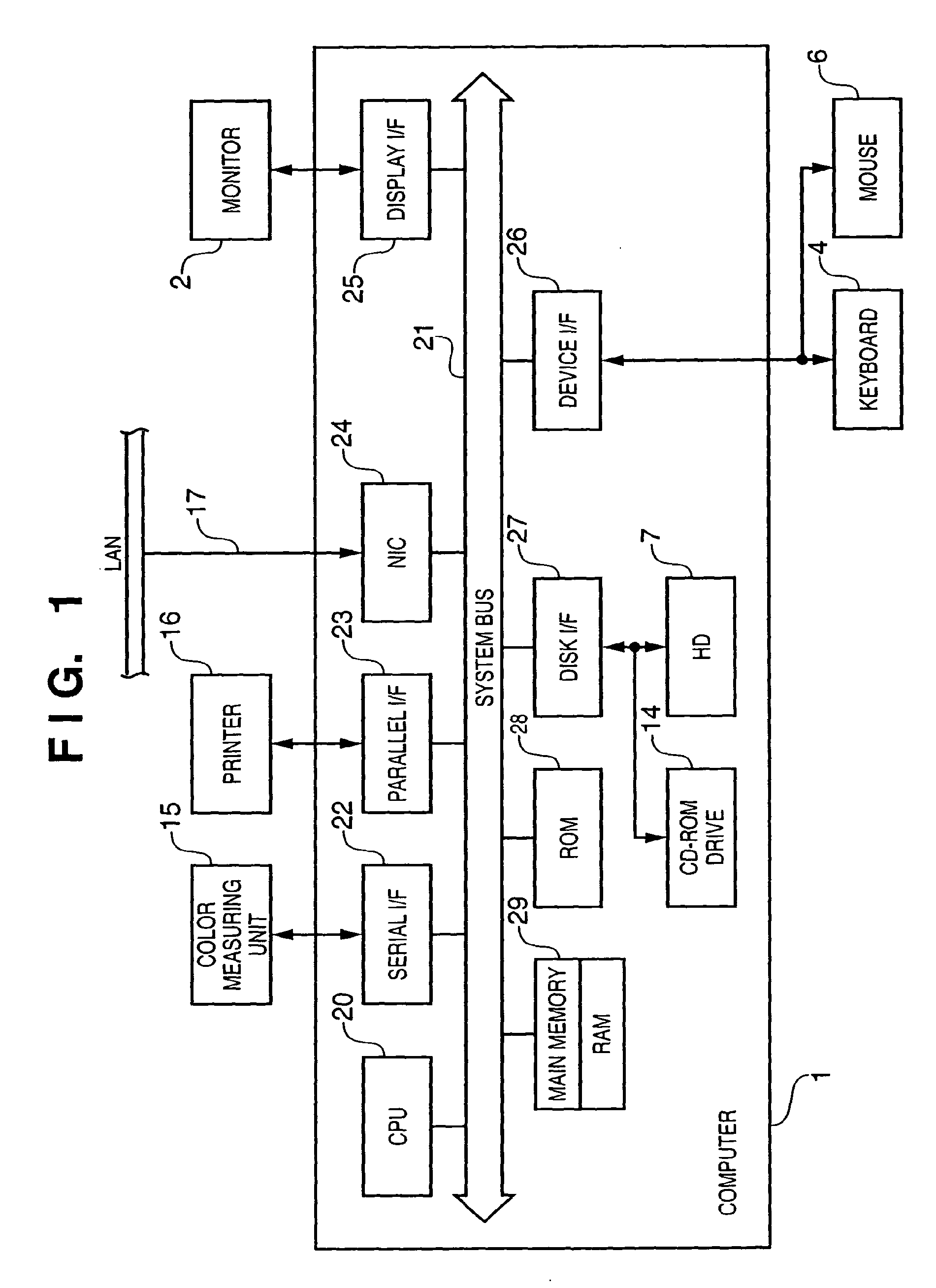

InactiveUS6480299B1Digitally marking record carriersDigital computer detailsPattern recognitionICC profile

A color management method / apparatus generates image color matching and International Color Consortium (ICC) color printer profiles using a reduced number of color patch measurements. Color printer characterization, and the generation of ICC profiles usually require a large number of measured data points or color patches and complex interpolation techniques. This invention provides an optimization method / apparatus for performing LAB to CMYK color space conversion, gamut mapping, and gray component replacement. A gamut trained network architecture performs LAB to CMYK color space conversion to generate a color profile lookup table for a color printer, or alternatively, to directly control the color printer in accordance with the a plurality of color patches that accurately. represent the gamut of the color printer. More specifically, a feed forward neural network is trained using an ANSI / IT-8 basic data set consisting of 182 data points or color patches, or using a lesser number of data points such as 150 or 101 data points when redundant data points within linear regions of the 182 data point set are removed. A 5-to-7 neuron neural network architecture is preferred to perform the LAB to CMYK color space conversion as the profile lookup table is built, or as the printer is directly controlled. For each CMYK signal, an ink optimization criteria is applied, to thereby control ink parameters such as the total quantity of ink in each CMYK ink printed pixel, and / or to control the total quantity of black ink in each CMYK ink printed pixel.

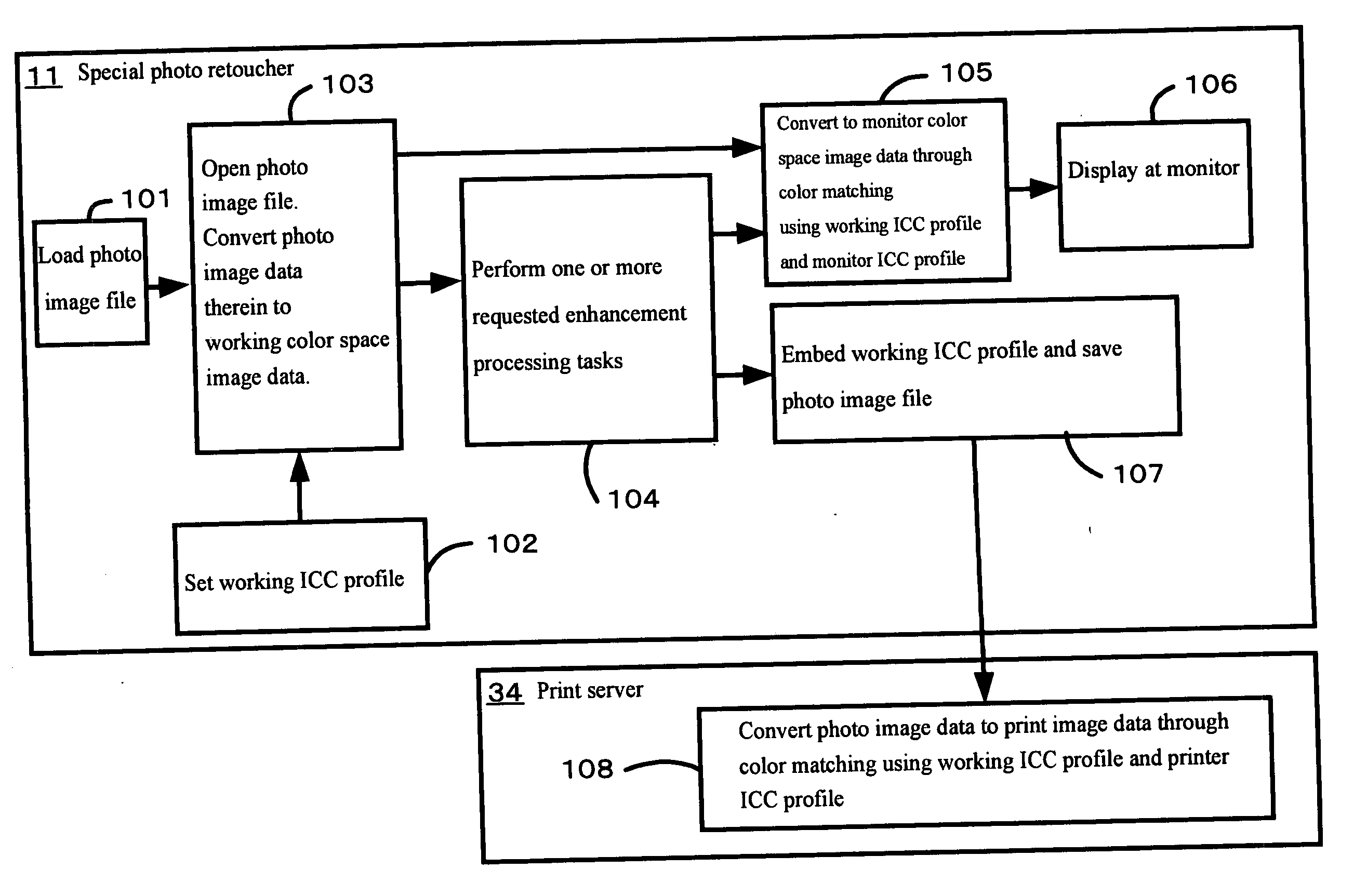

Owner:UNIV OF COLORADO THE REGENTS OF

Image retouching program

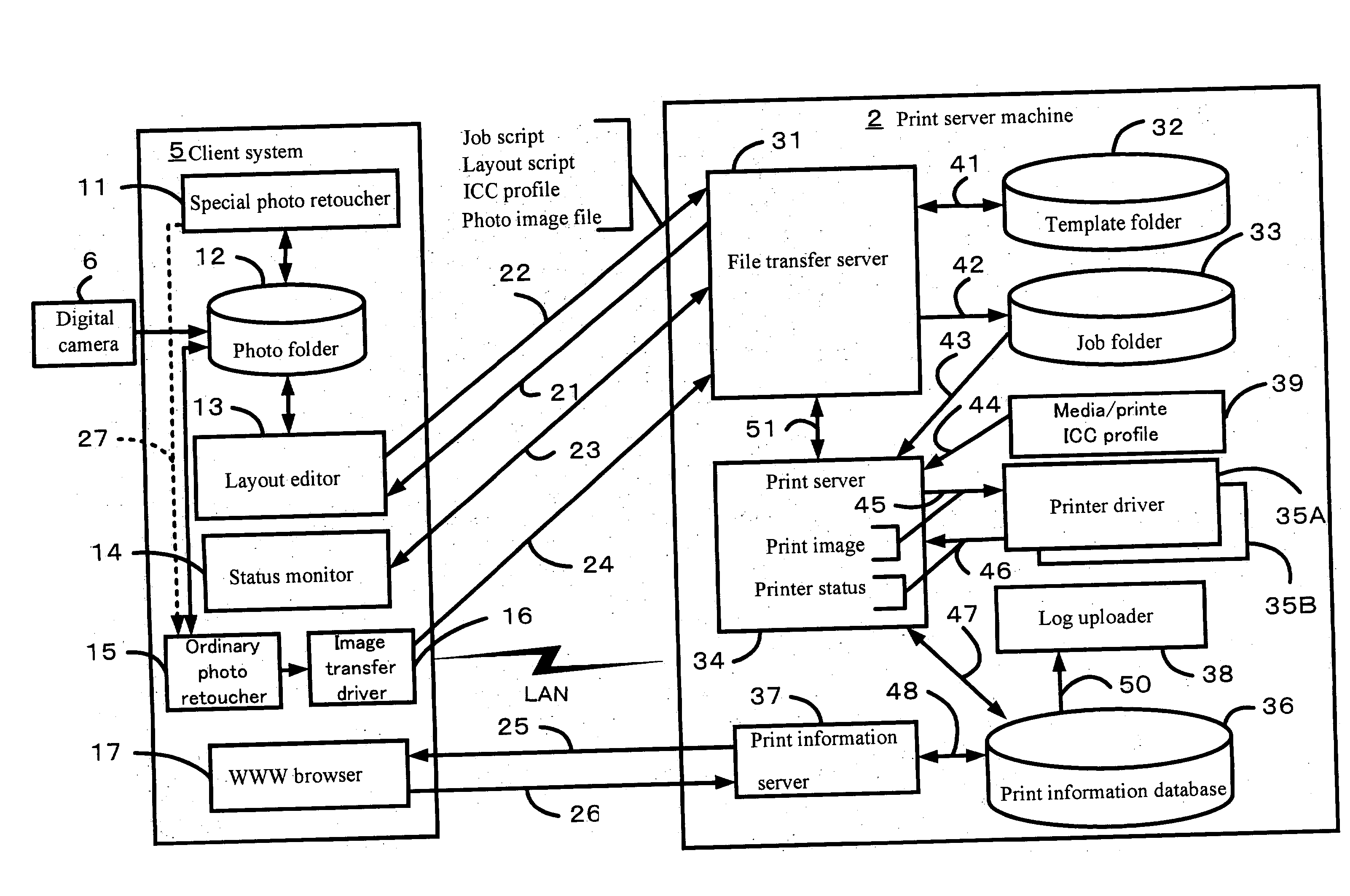

Provided is photo retouching software which is easy for photo studio personnel to use. Upon opening photo image(s), special photo retoucher 11 converts photo image data thereof to working color space image data. At such time(s), if working ICC profile(s) is / are set which is / are different from ICC profile(s) previously embedded in such photo image file(s), color perceptual matching is carried out on the photo image data thereof based on such embedded ICC profile(s) and working ICC profile(s) when such photo image file(s) is / are opened. Furthermore, when such photo image(s) is / are displayed at monitor(s), such image data is converted to monitor color space image data through color matching using working ICC profile(s) and monitor ICC profile(s).

Owner:138 EAST LCD ADVANCEMENTS LTD

Image retouching program

InactiveUS20070030506A1Easy to useDigitally marking record carriersDigital computer detailsICC profileData translation

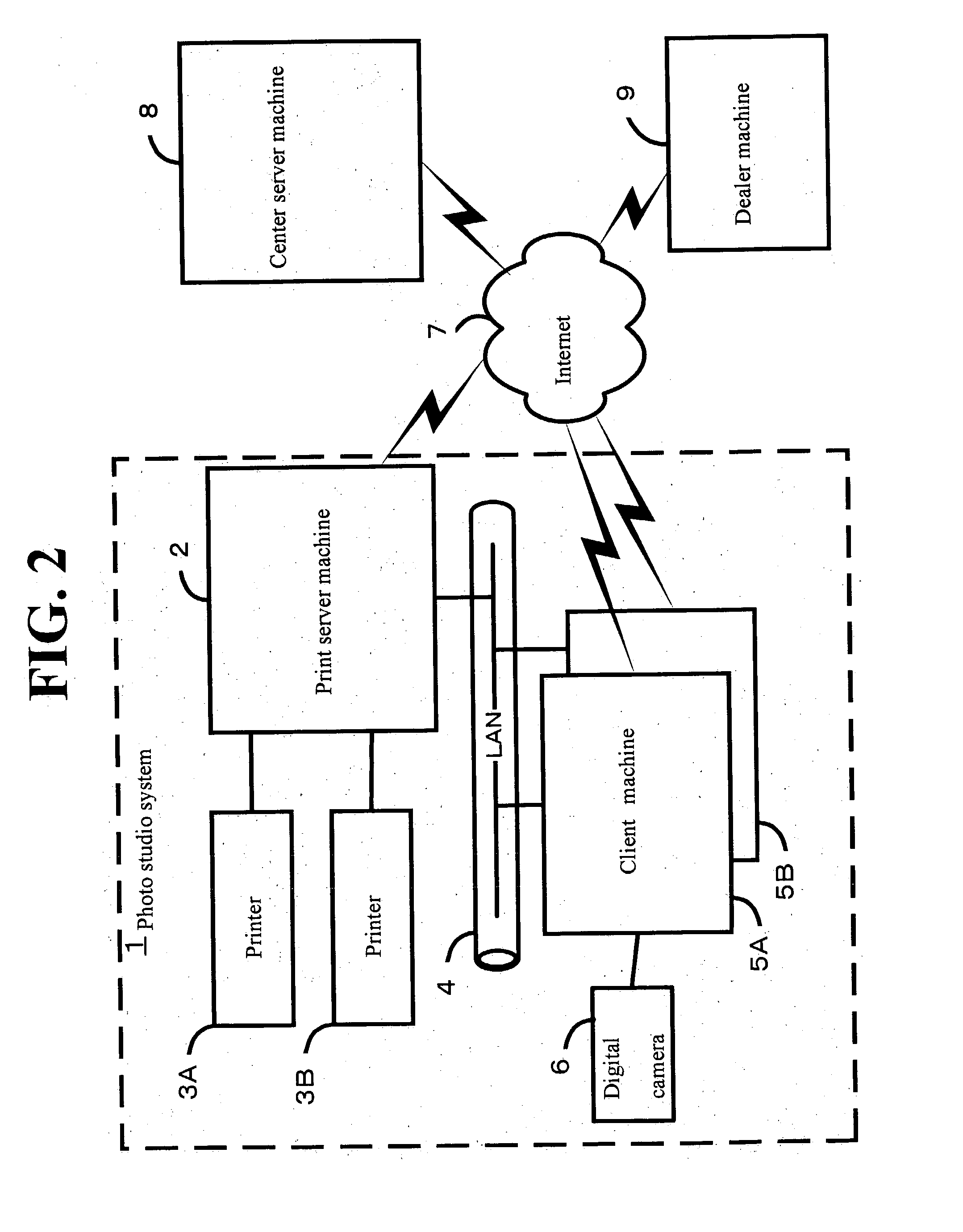

Provided is photo retouching software which is easy for photo studio personnel to use. Upon opening photo image(s), special photo retoucher 11 converts photo image data thereof to working color space image data. At such time(s), if working ICC profile(s) is / are set which is / are different from ICC profile(s) previously embedded in such photo image file(s), color perceptual matching is carried out on the photo image data thereof based on such embedded ICC profile(s) and working ICC profile(s) when such photo image file(s) is / are opened. Furthermore, when such photo image(s) is / are displayed at monitor(s), such image data is converted to monitor color space image data through color matching using working ICC profile(s) and monitor ICC profile(s).

Owner:138 EAST LCD ADVANCEMENTS LTD

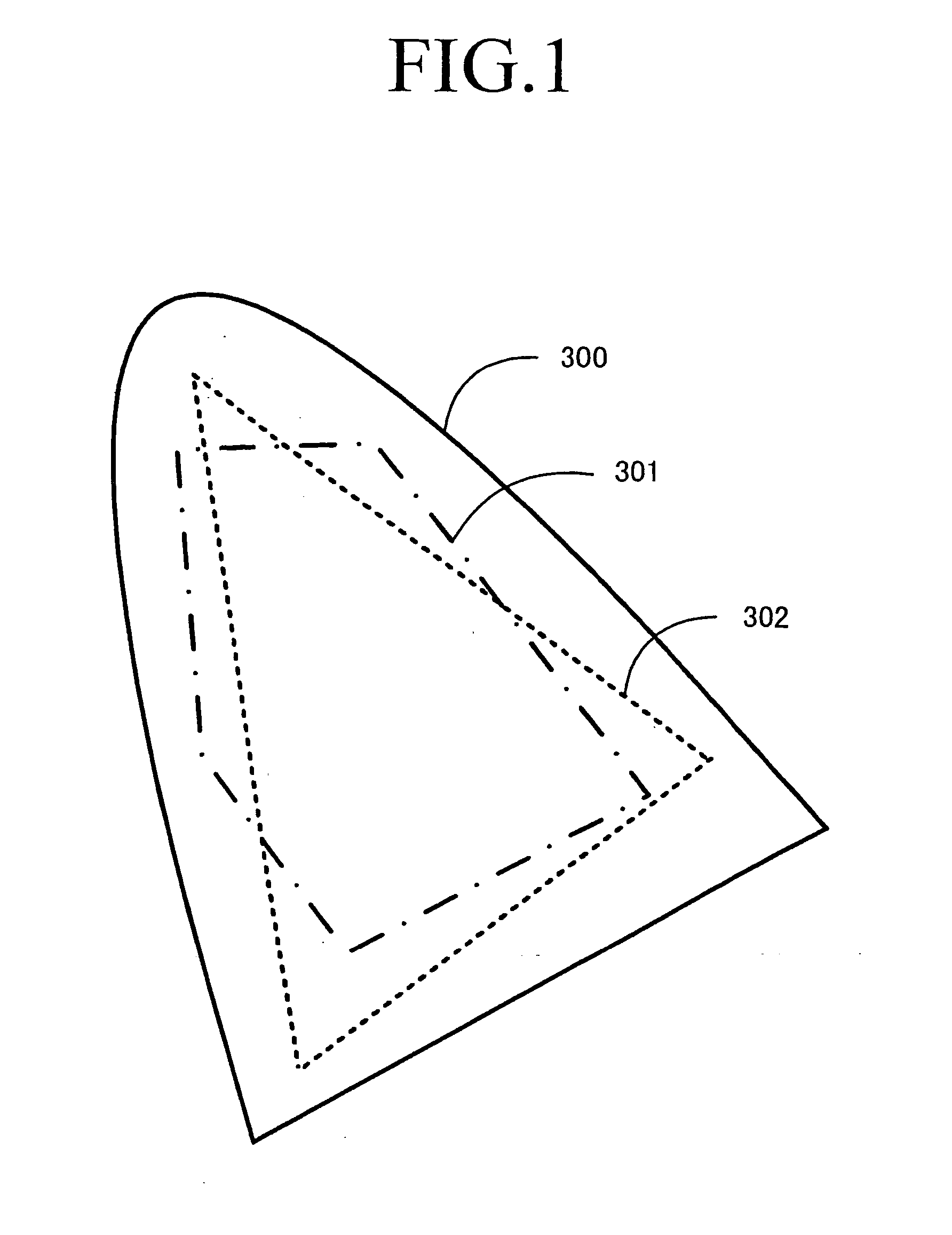

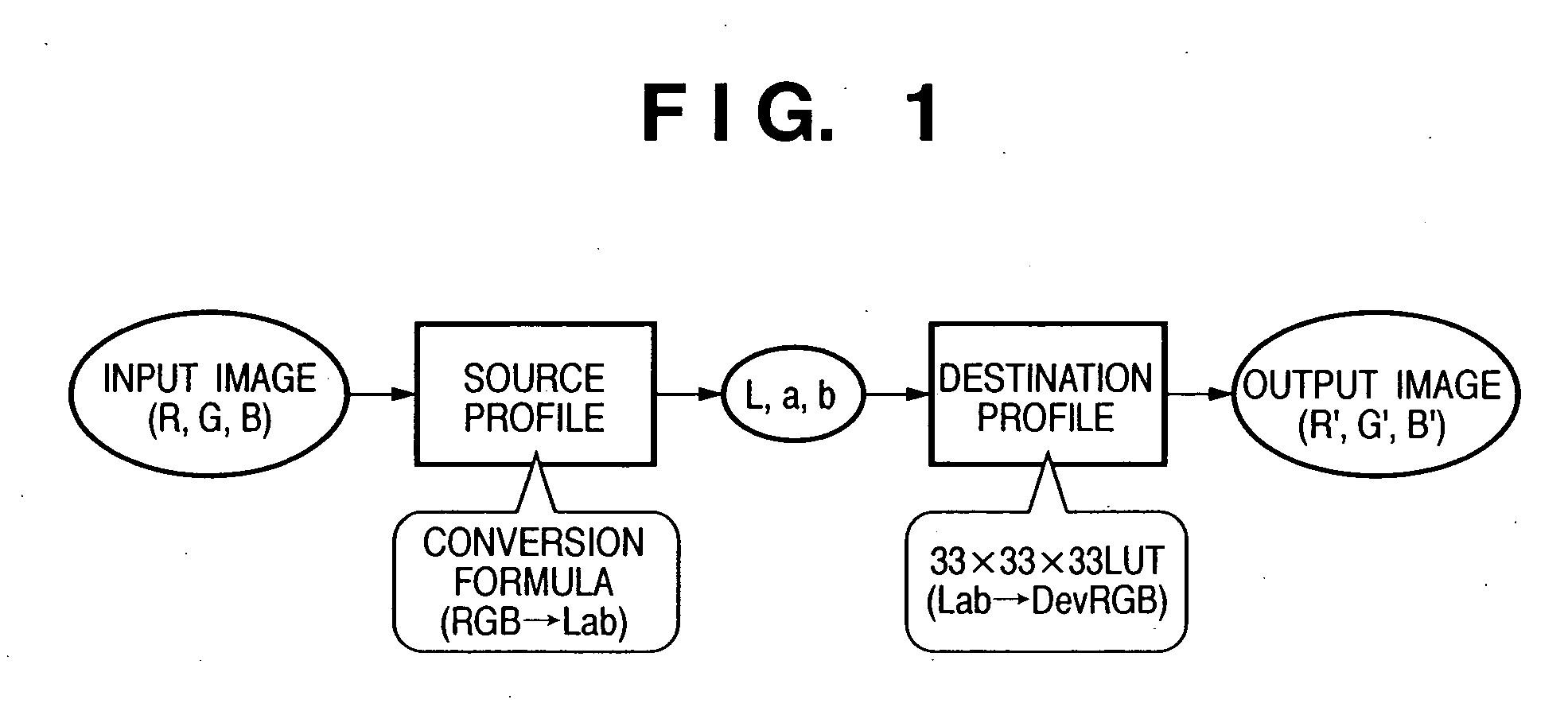

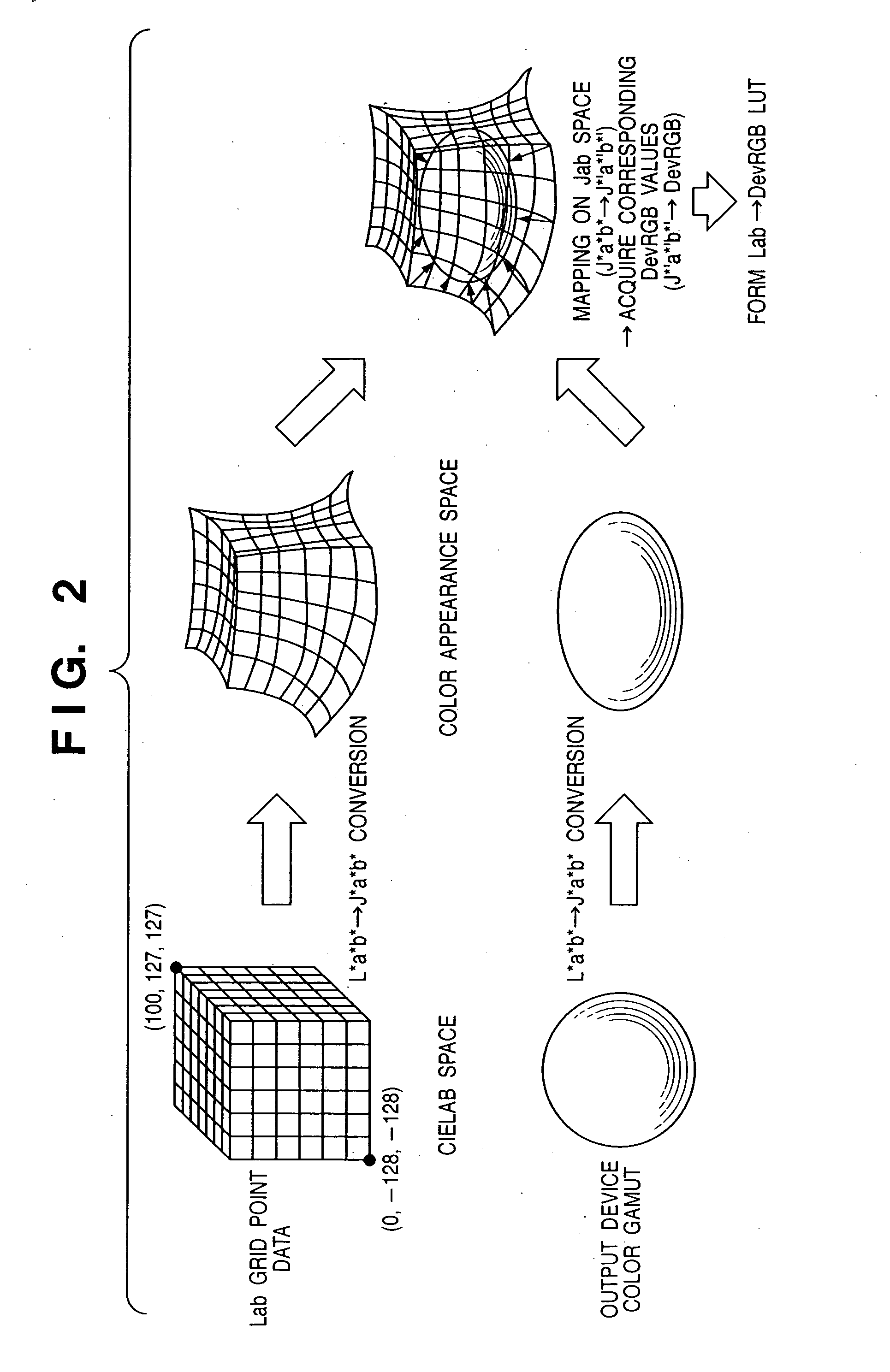

Color processing method and apparatus thereof

InactiveUS20050219585A1High quality imagingDigitally marking record carriersDigital computer detailsICC profileGamut

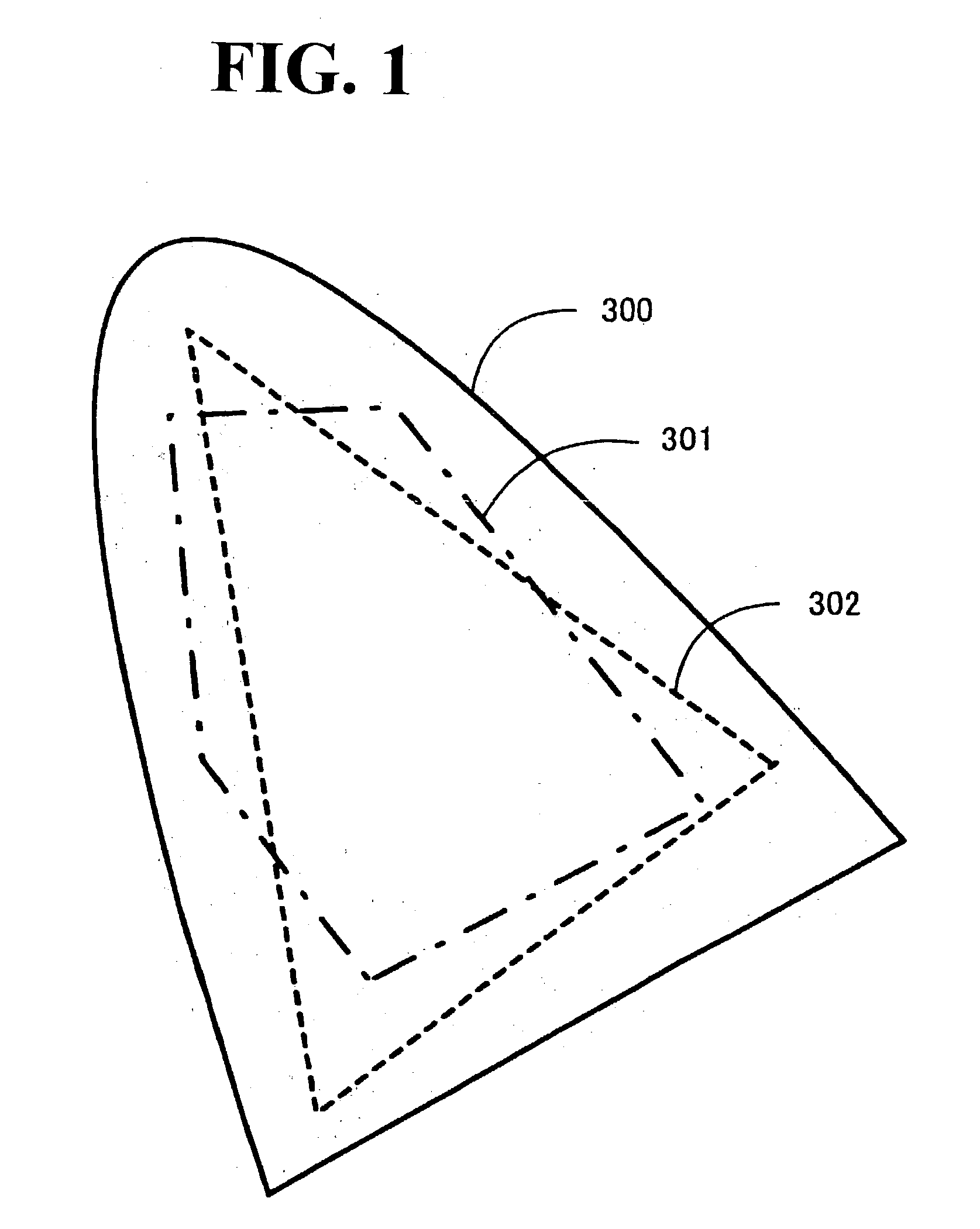

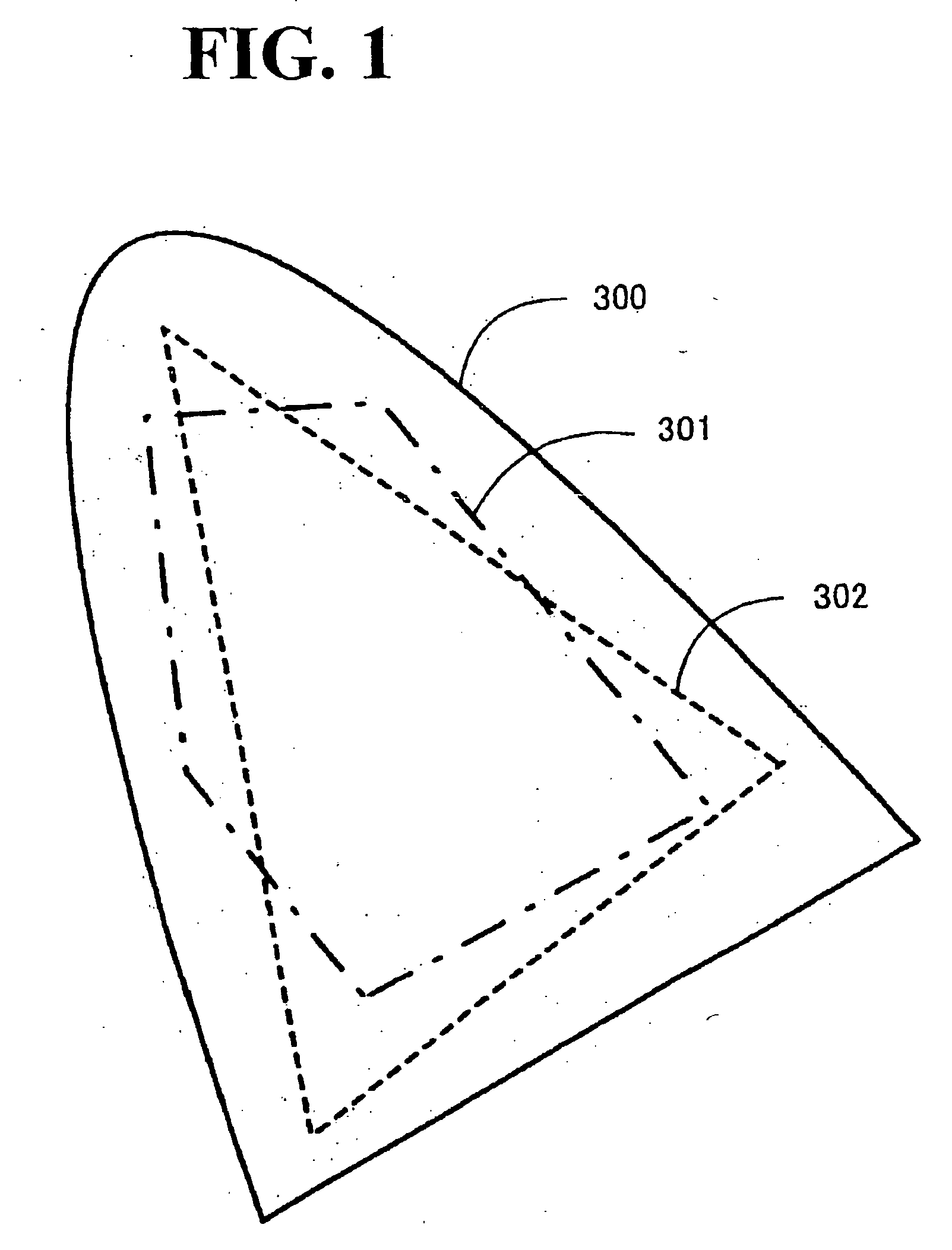

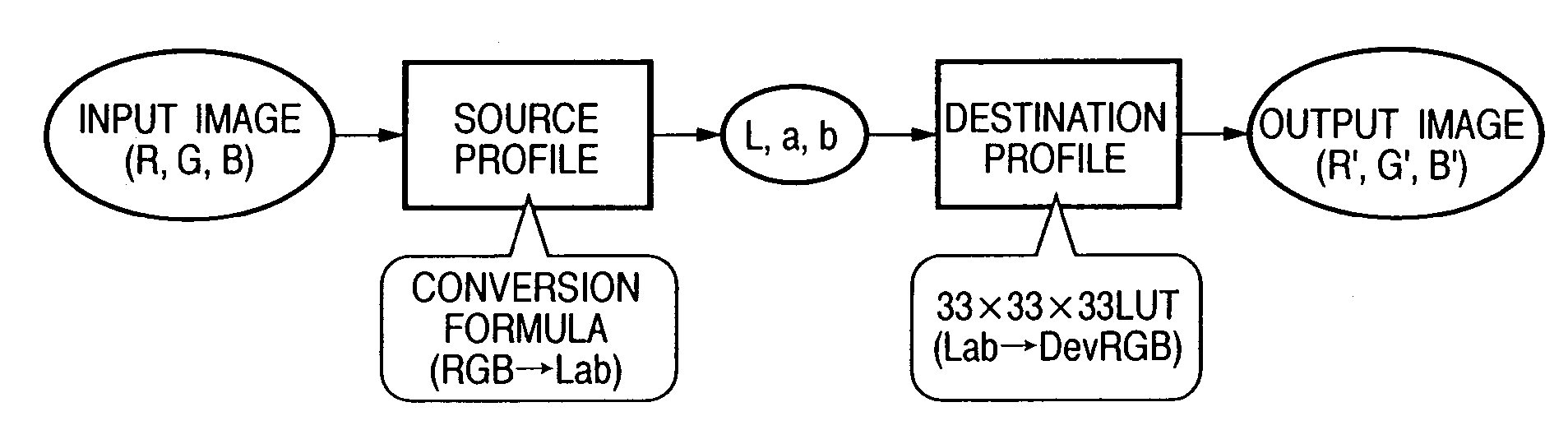

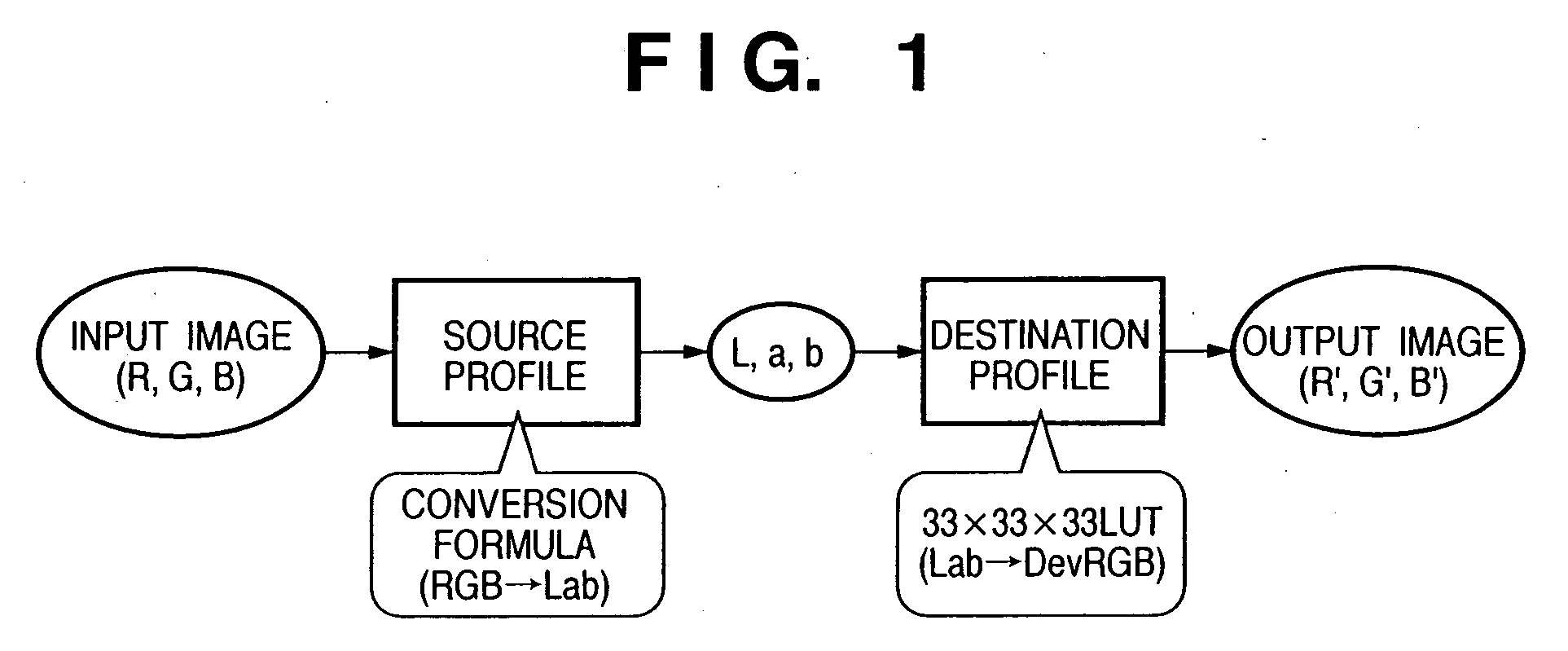

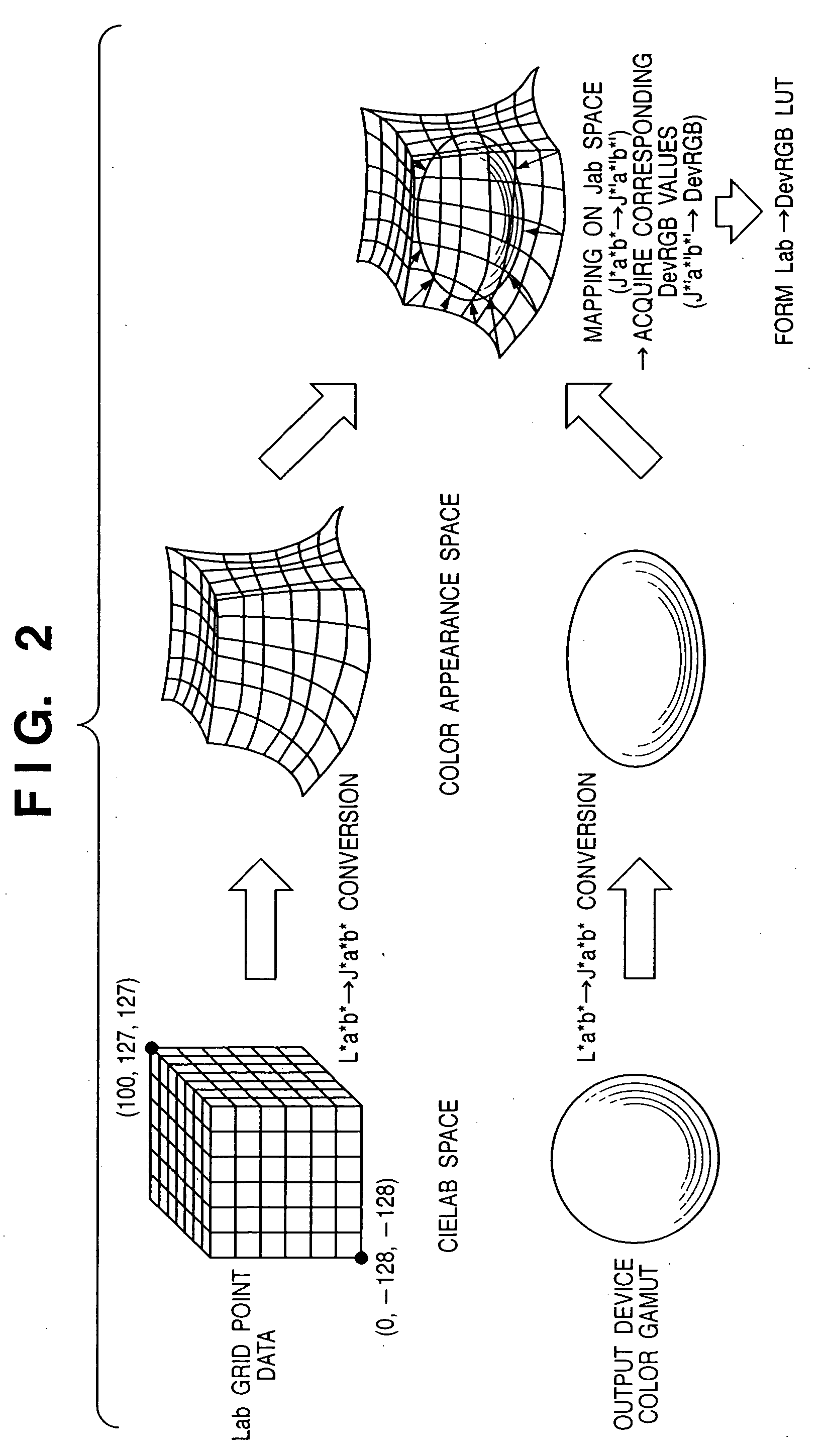

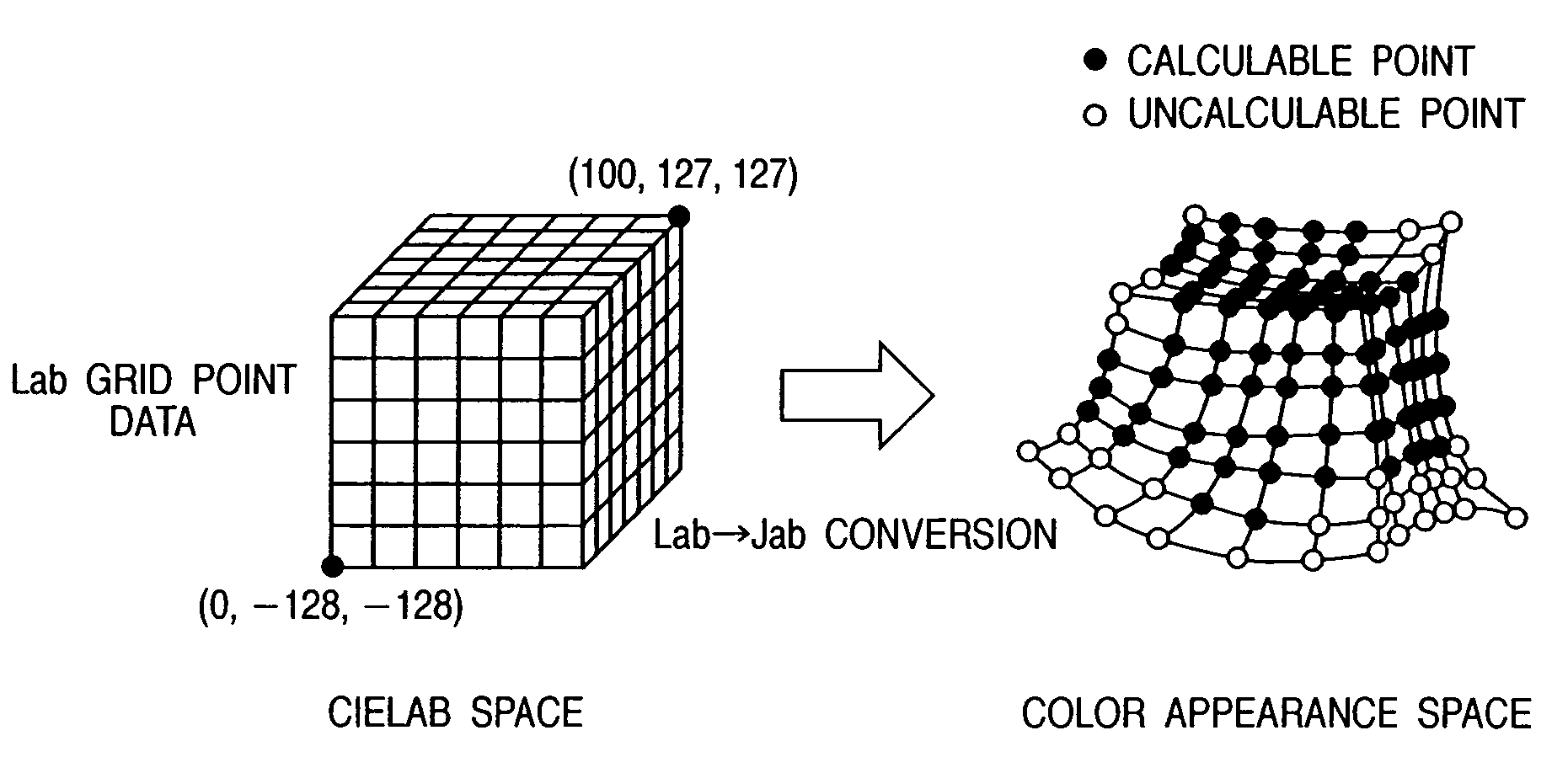

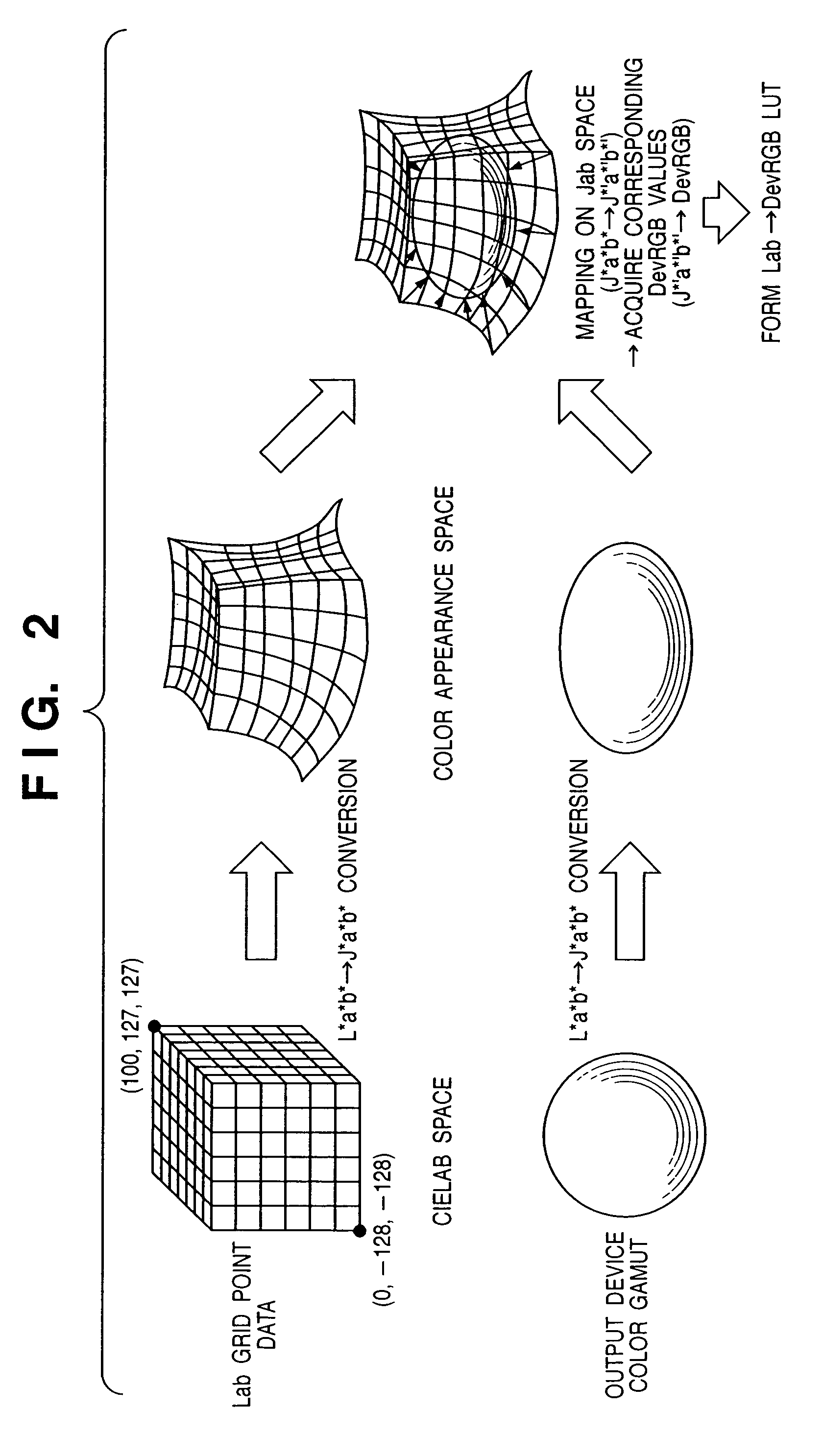

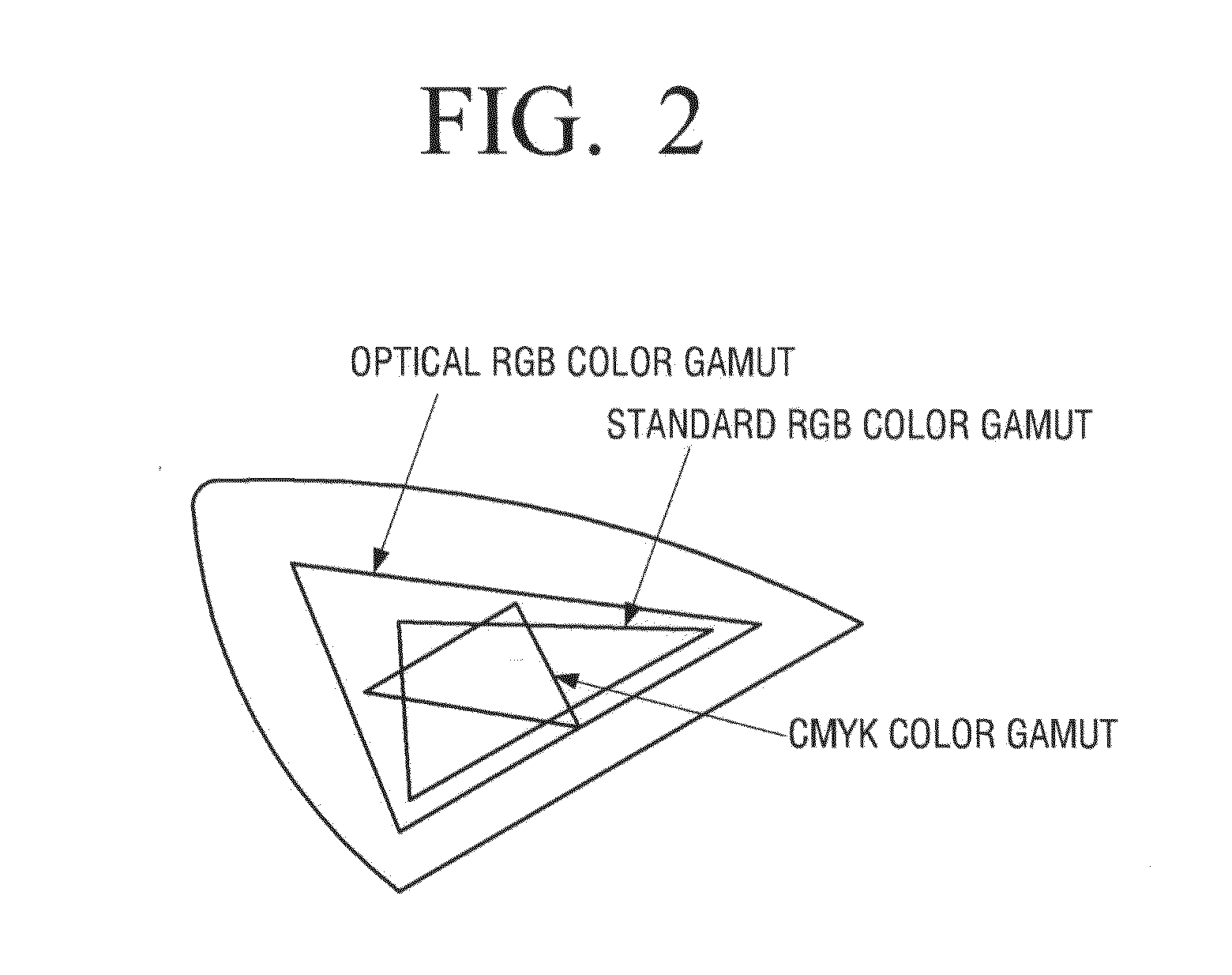

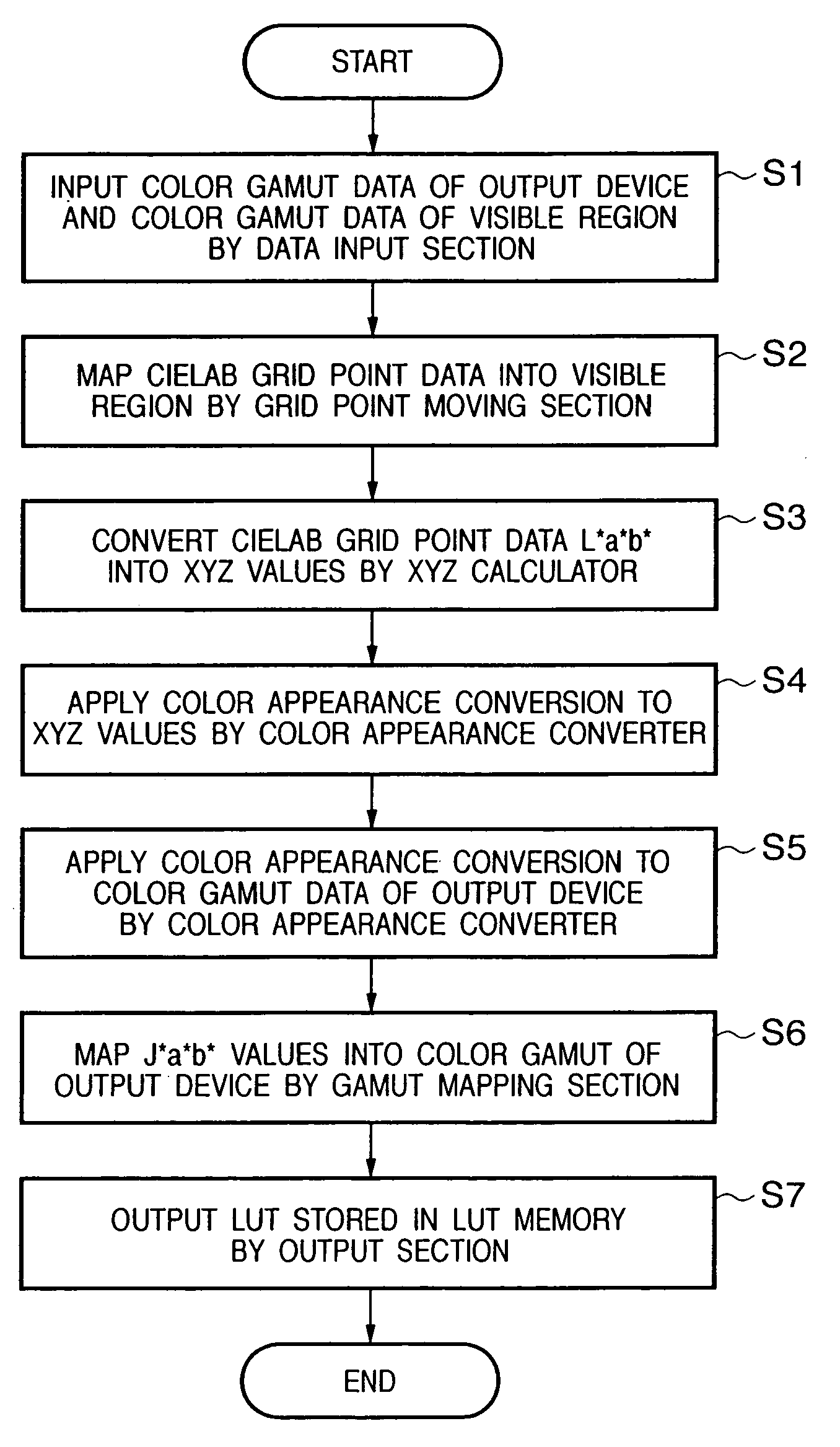

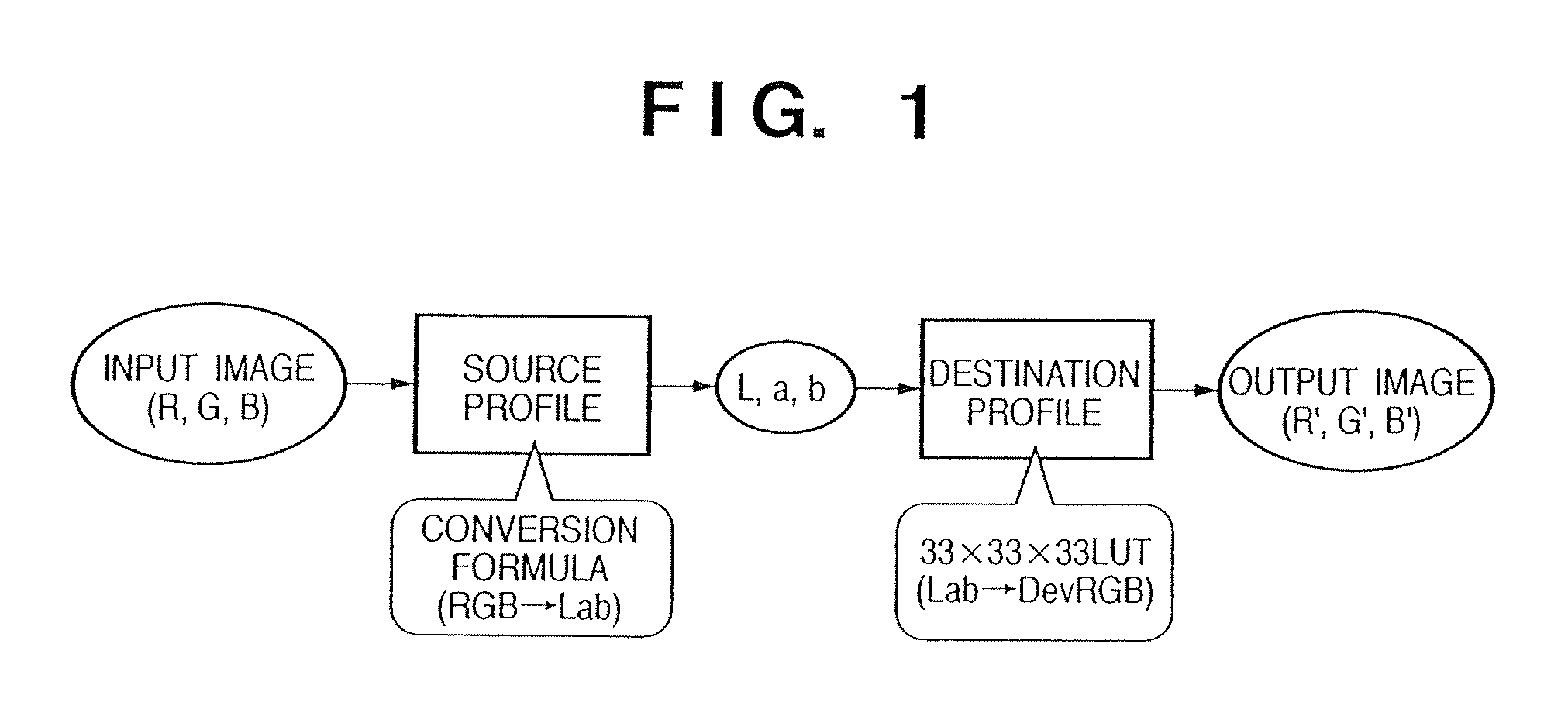

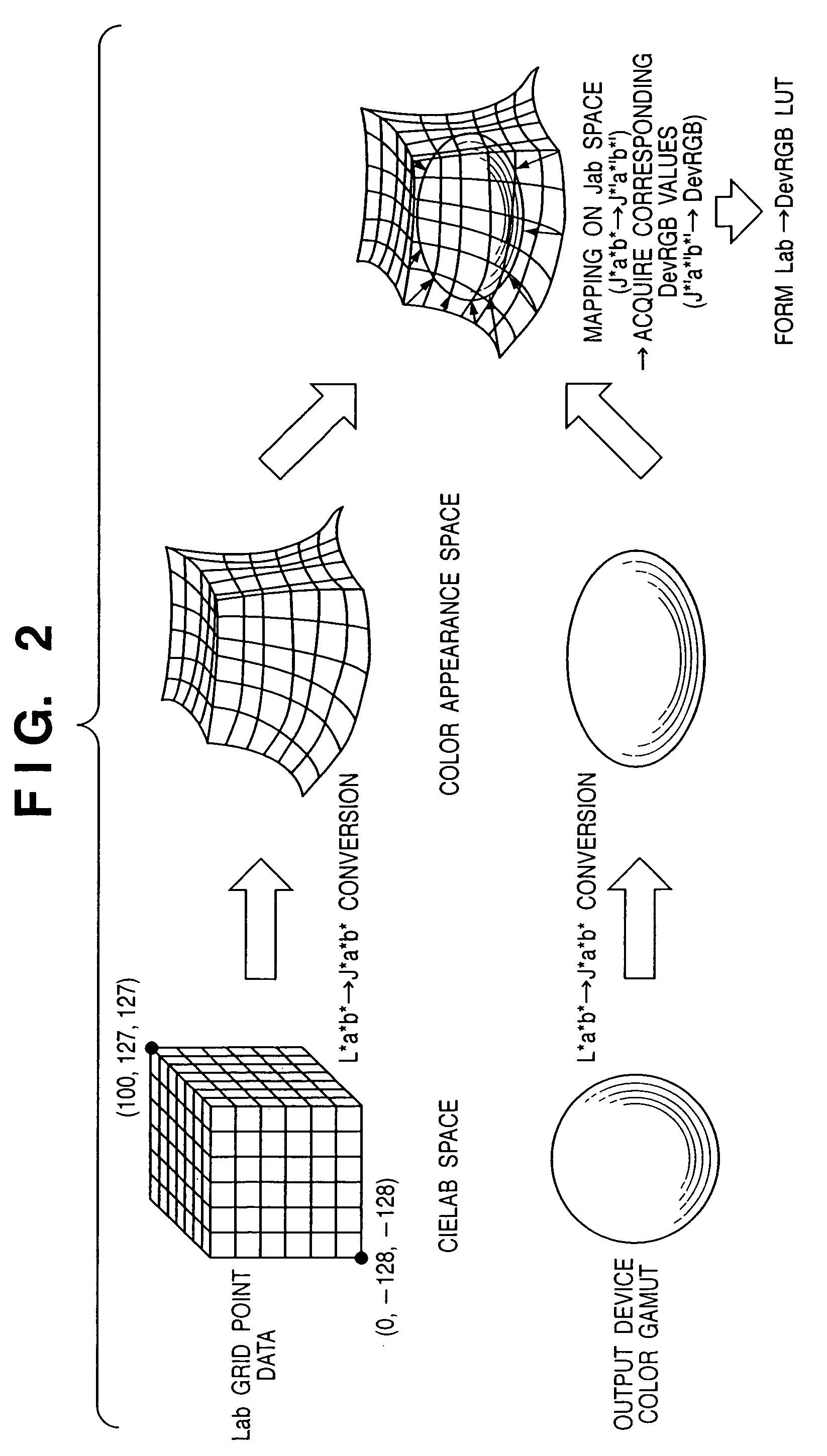

It is desired to adopt gamut mapping using a color appearance space in the processing system of an ICC profile. Upon generating an LUT complying with the ICC profile format, a grid point outside of the visible region on the CIELAB space is moved into the visible region. The Lab values of the grid point are converted into XYZ values, which undergo color appearance conversion to acquire color appearance values. The acquired color appearance values are mapped on the color gamut of a predetermined device.

Owner:CANON KK

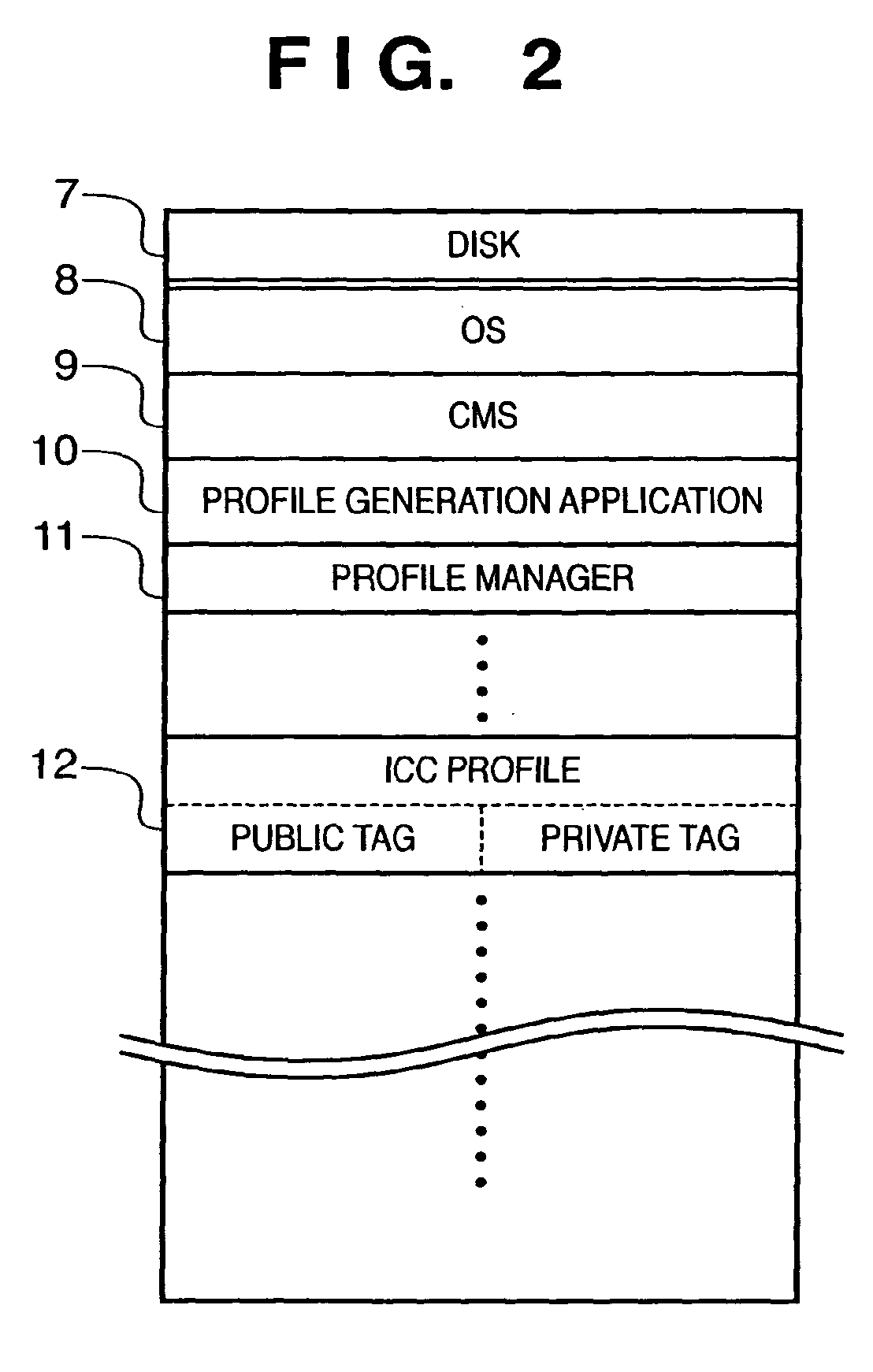

Image processing apparatus and its method, and control method

InactiveUS7369271B2Accurate descriptionDigitally marking record carriersDigital computer detailsICC profileImaging processing

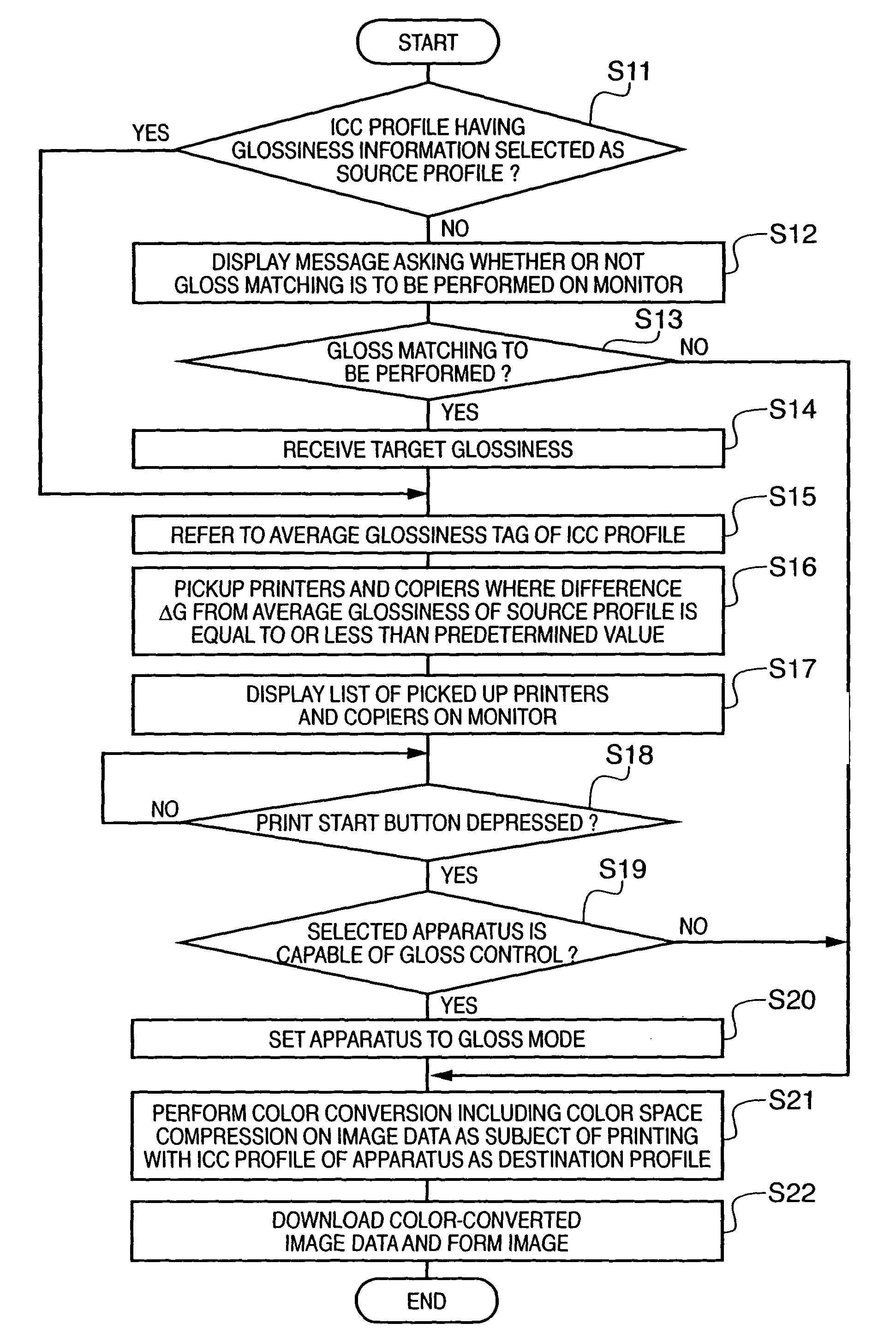

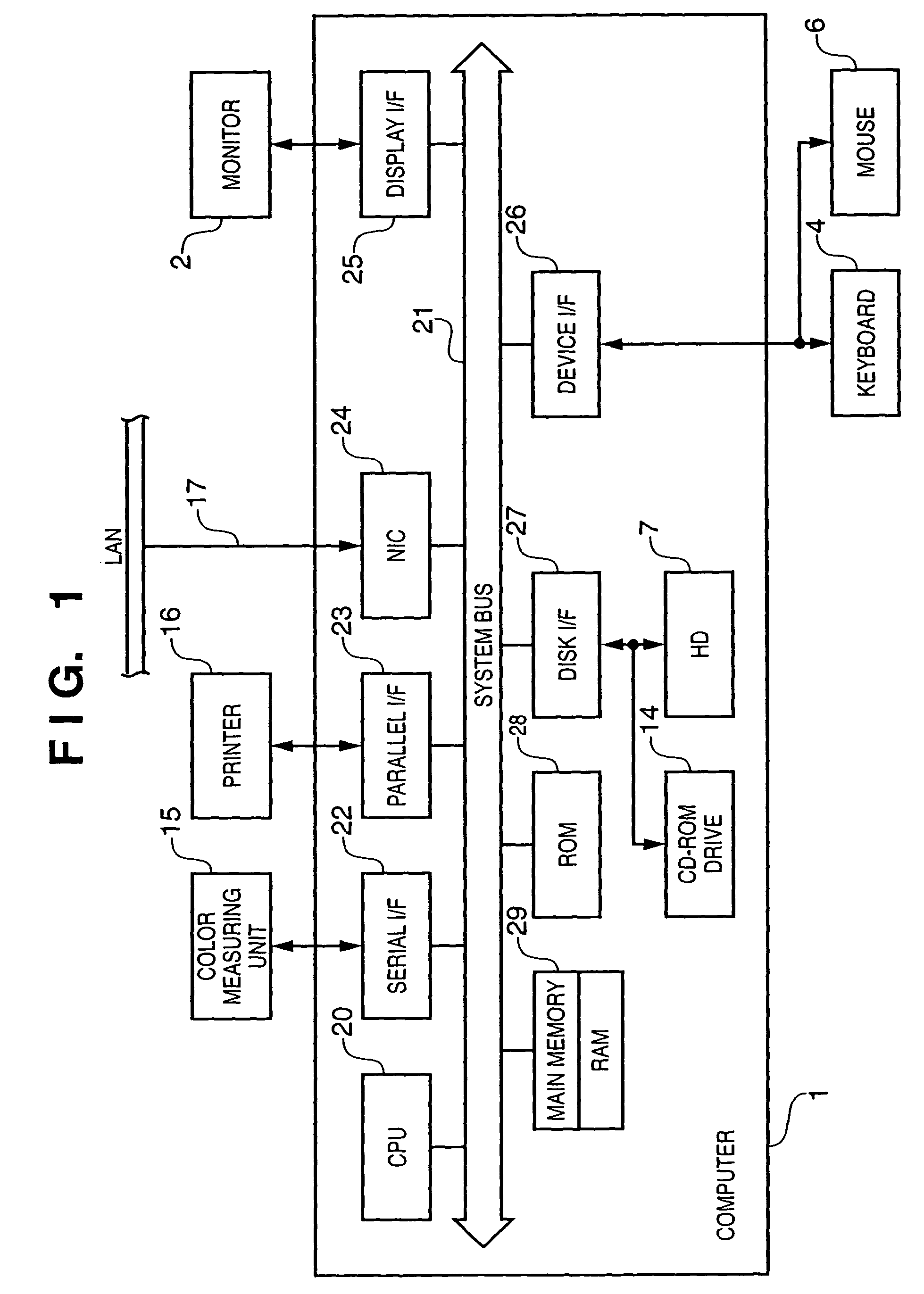

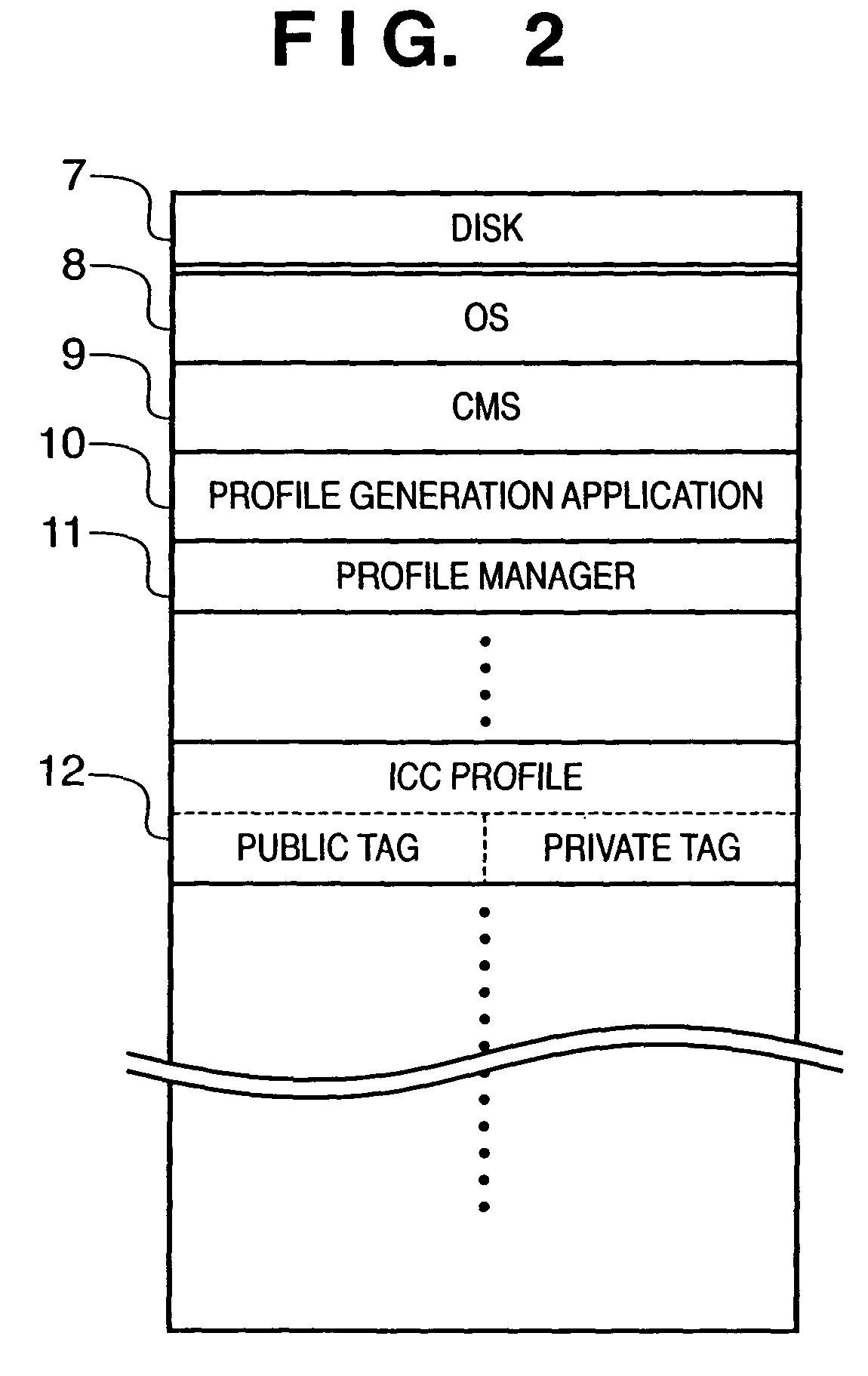

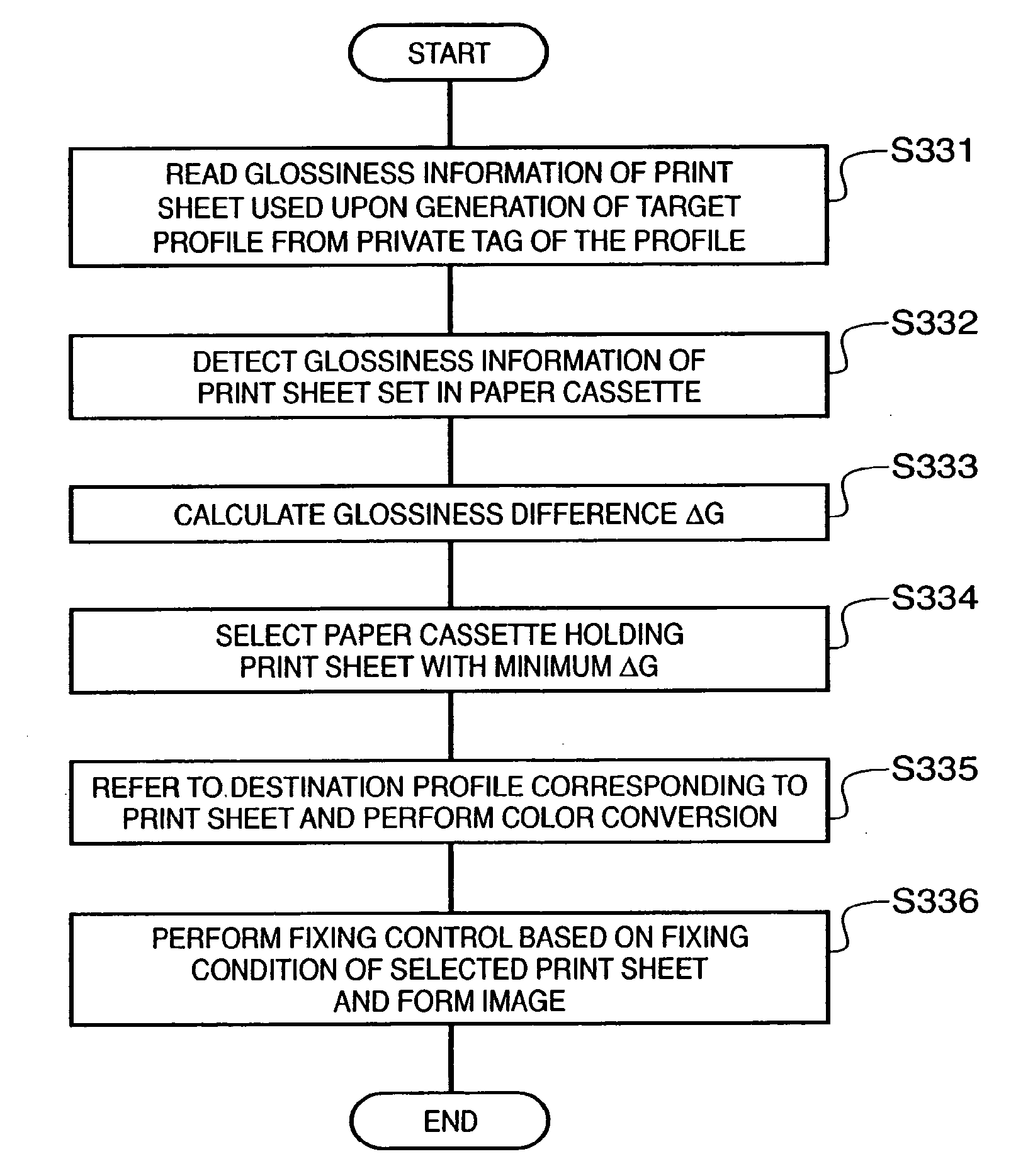

An ICC profile includes brief gloss information indicating glossy / matte attribute as attribute information, however, gloss matching cannot be performed with the 2 options. In a case where embedding of glossiness information into the ICC profile is designated, glossiness information is obtained from a color chart placed on an original plate of a color copier, and the obtained glossiness information is described in a private tag of the ICC profile.

Owner:CANON KK

Method to retrieve a gamut mapping strategy

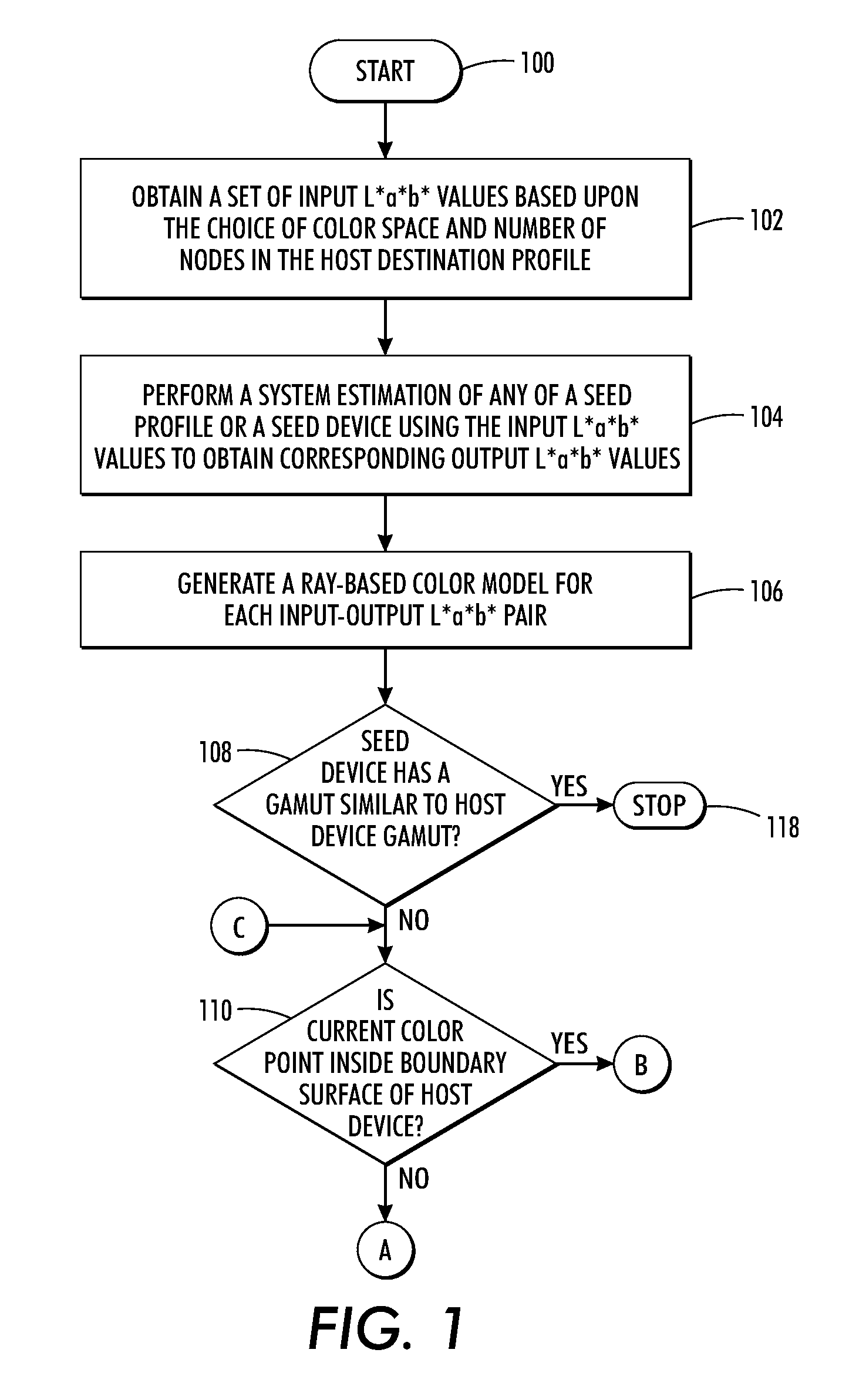

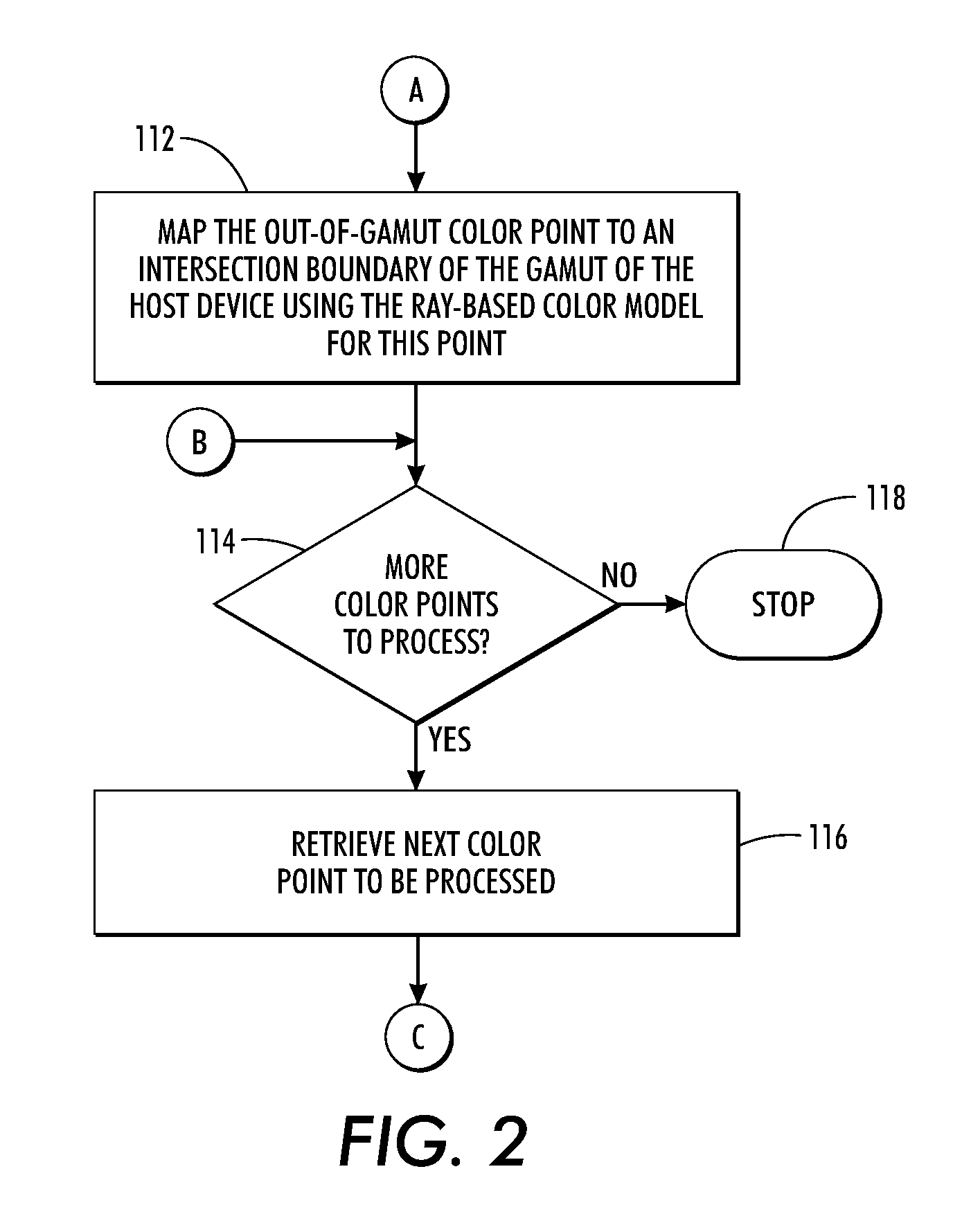

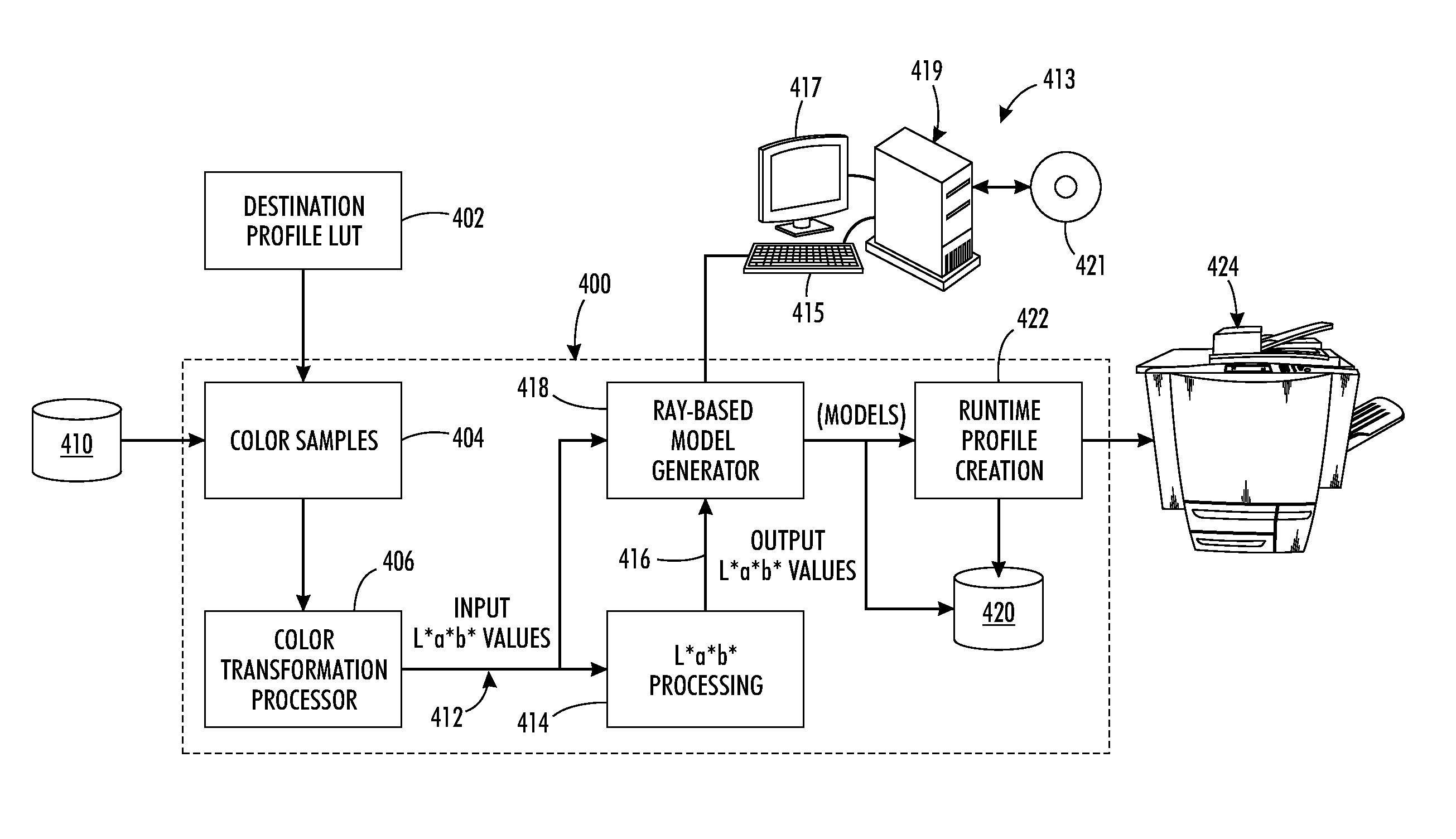

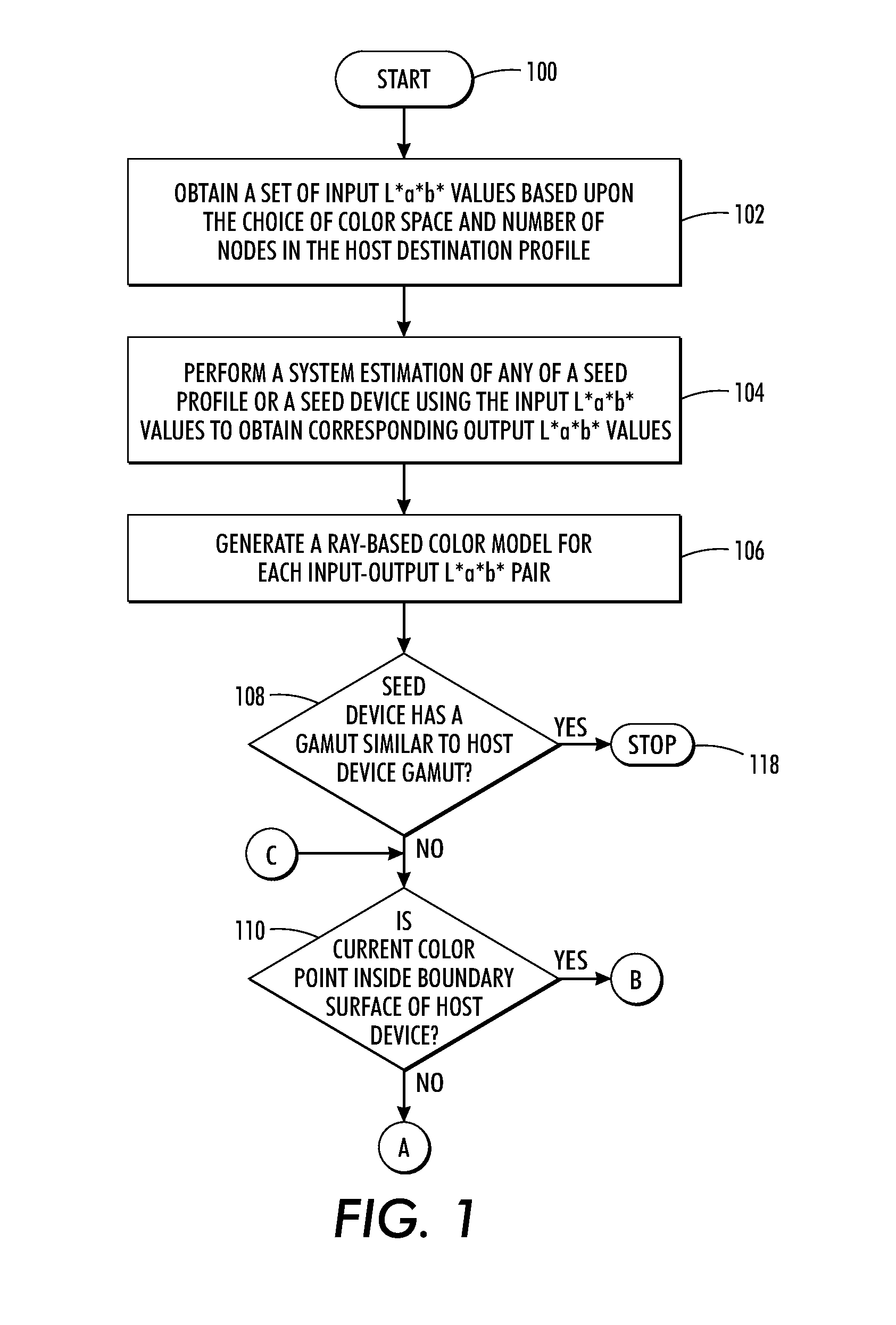

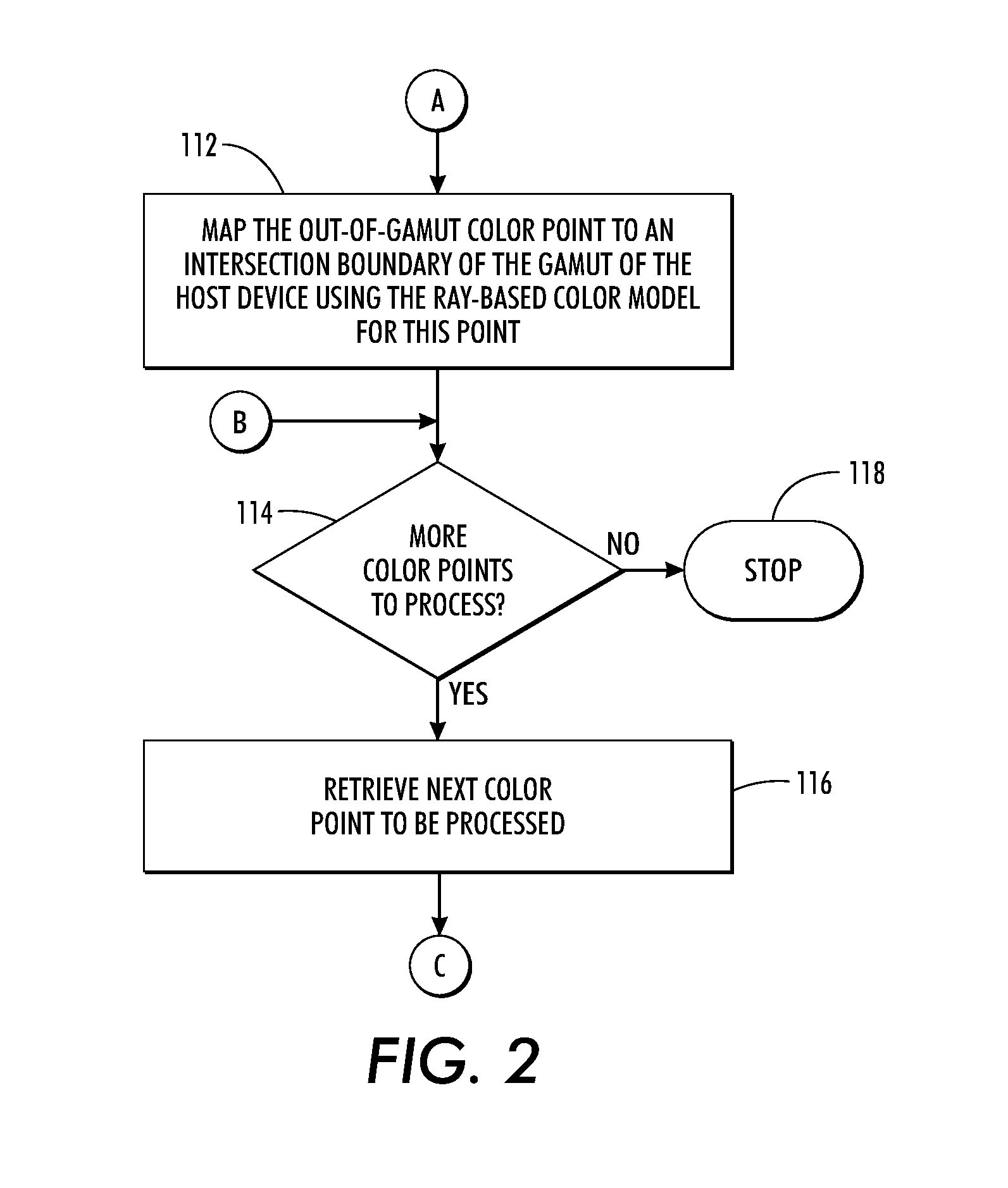

ActiveUS8379267B2Exact reproductionDigitally marking record carriersDigital computer detailsHard codingICC profile

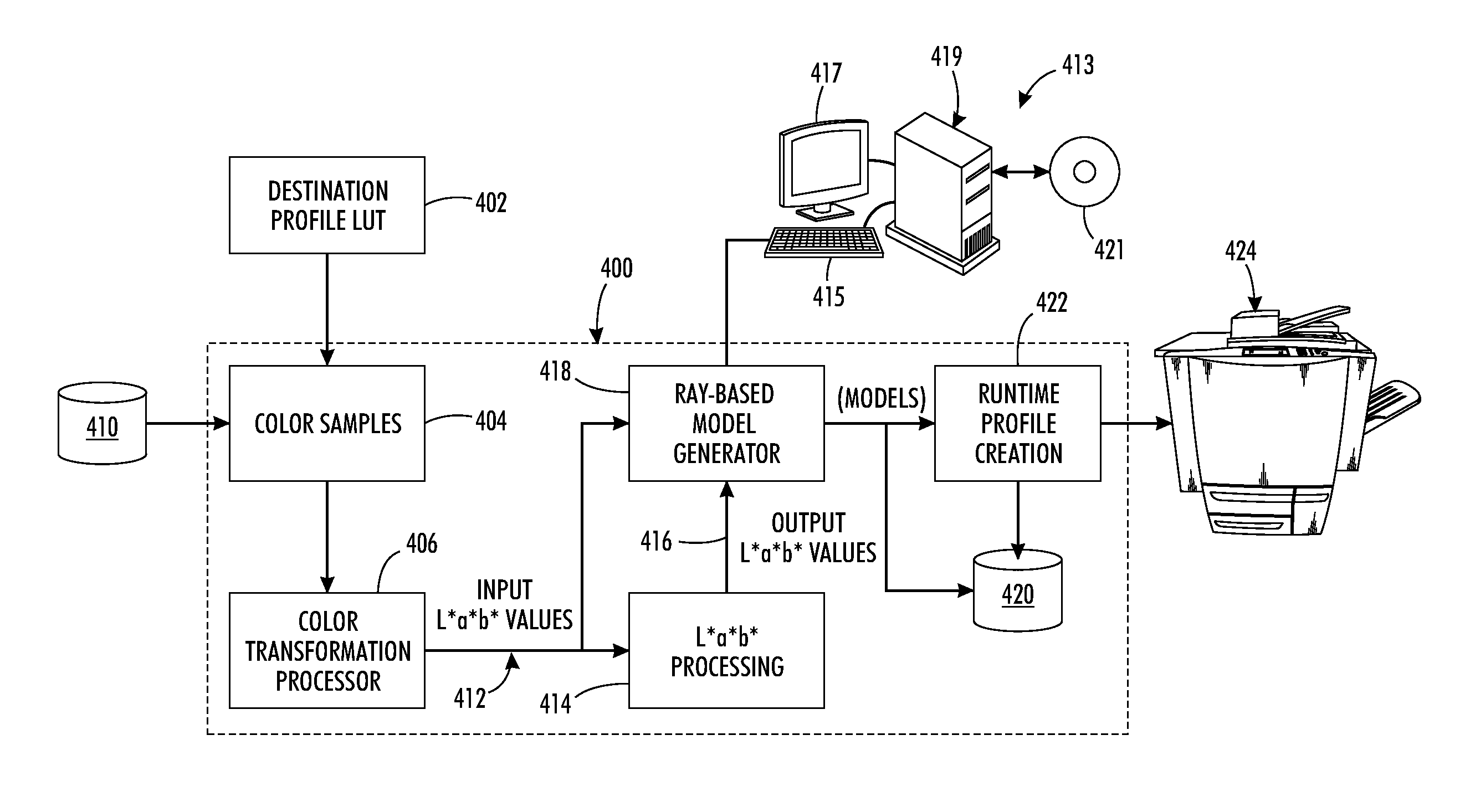

What is disclosed is a novel system and method for retrieving a gamut mapping for a color device. A ray-based model is derived from a system estimation of either a seed profile or a seed device. The model is hard coded inside a run-time ICC profile creation algorithm. The runtime profile generation code can be optimized for a variety of gamut mapping scenarios. The generated profile is provided to an imaging system wherein out-of-gamut colors are mapped to the color gamut of the host device. The present method provides an accurate way to reproduce colors of images by retrieving the gamut mapping from profiles or from the color device that use destination profiles for rendering images.

Owner:XEROX CORP

Colour management method in digital proofing

InactiveCN1467566AOvercoming the defects of unsatisfactory resultsColour-separation/tonal-correctionColor testICC profile

The invention discloses a color management method for the digital printing which comprises, printing IT8 color test table using the digital output equipment and printing equipment, performing measurement using color measuring spectrometer respectively, obtaining the ICC profile of the printing equipment and the ICC profile of the digital output equipment for color adjustment, acquiring the revised ICC profile, proceeding second revision, obtaining the digital sample manuscript of the digital output equipment.

Owner:SHANGHAI LONGYING COLOR PLATE MAKING

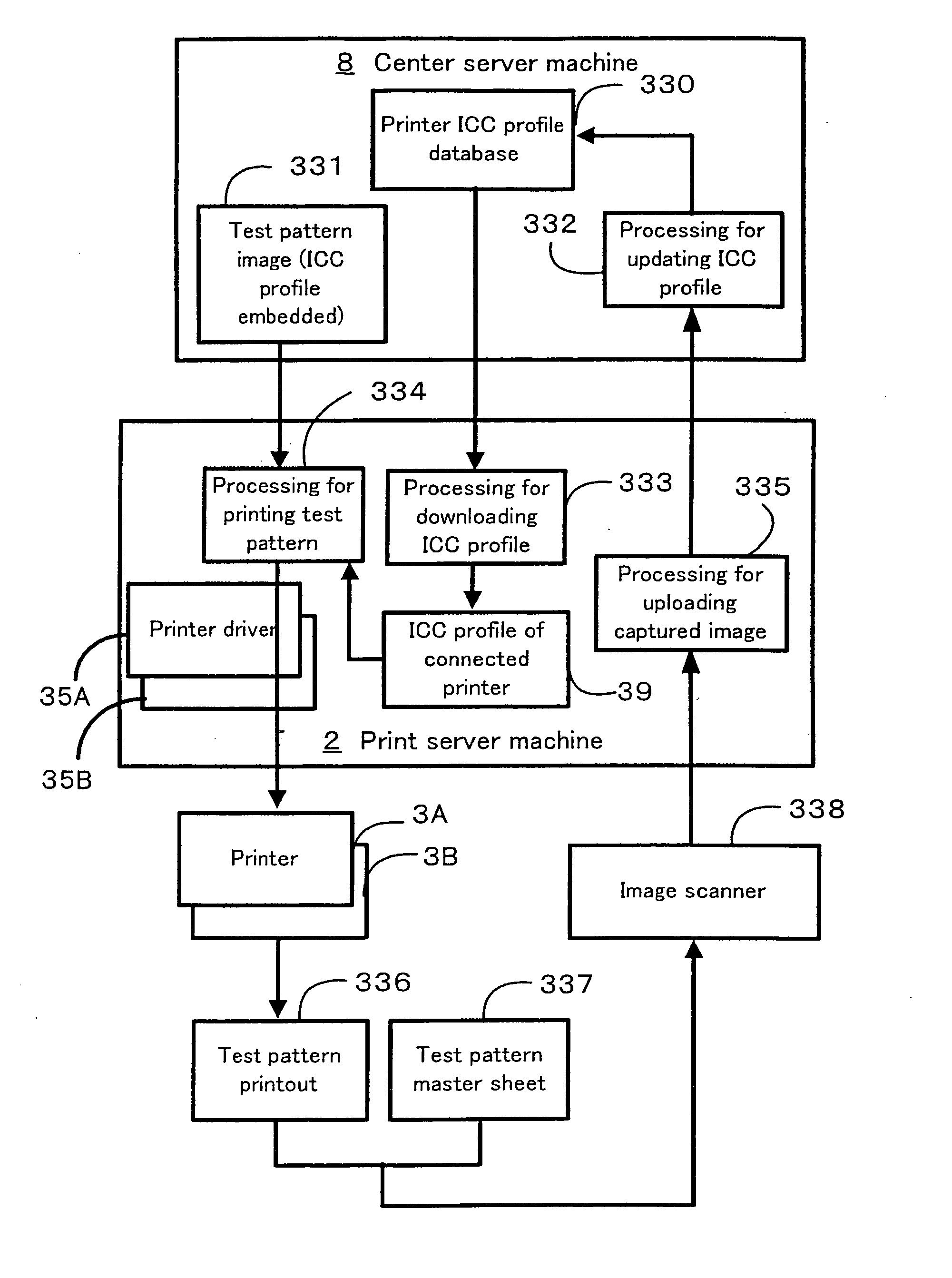

Print system and color print method

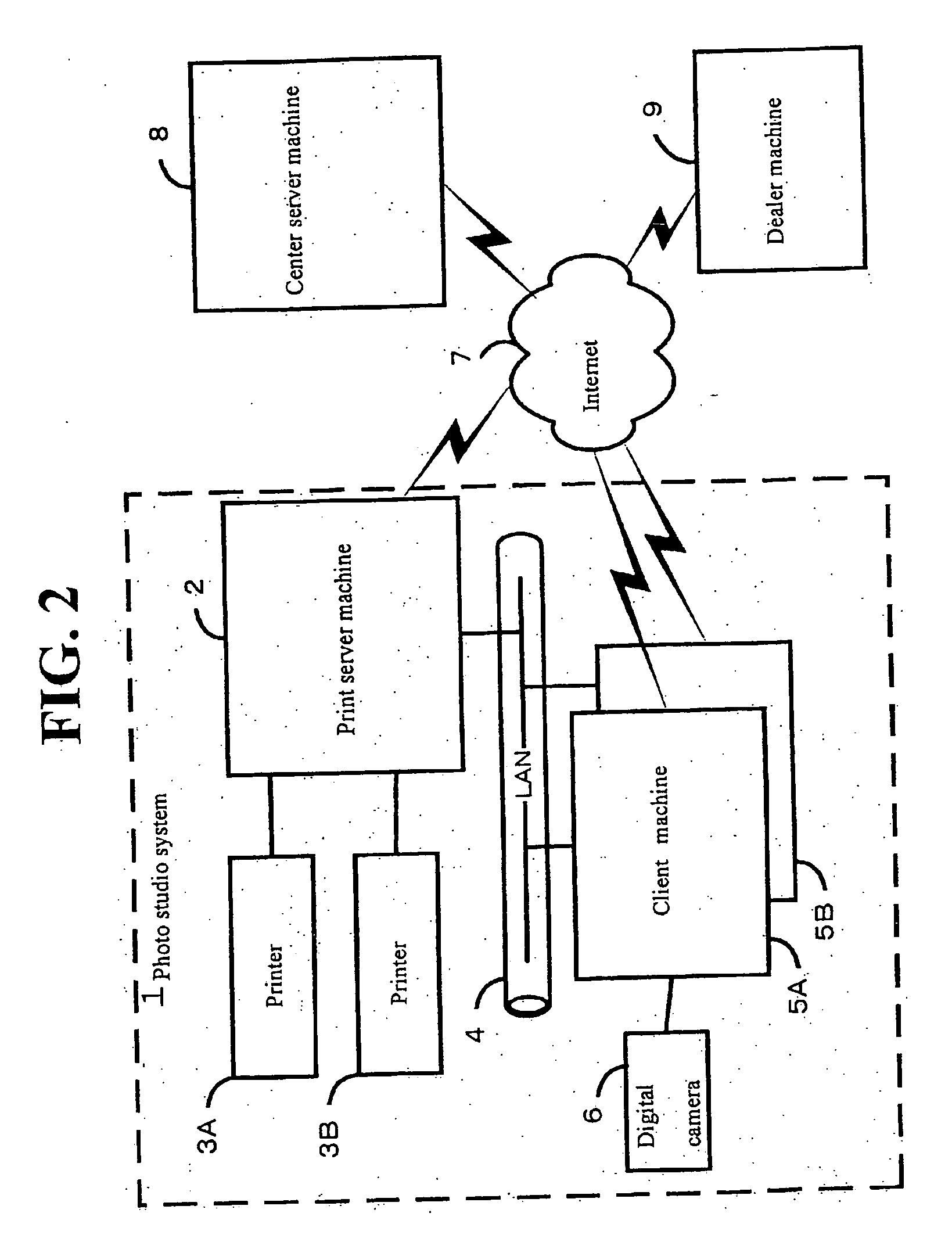

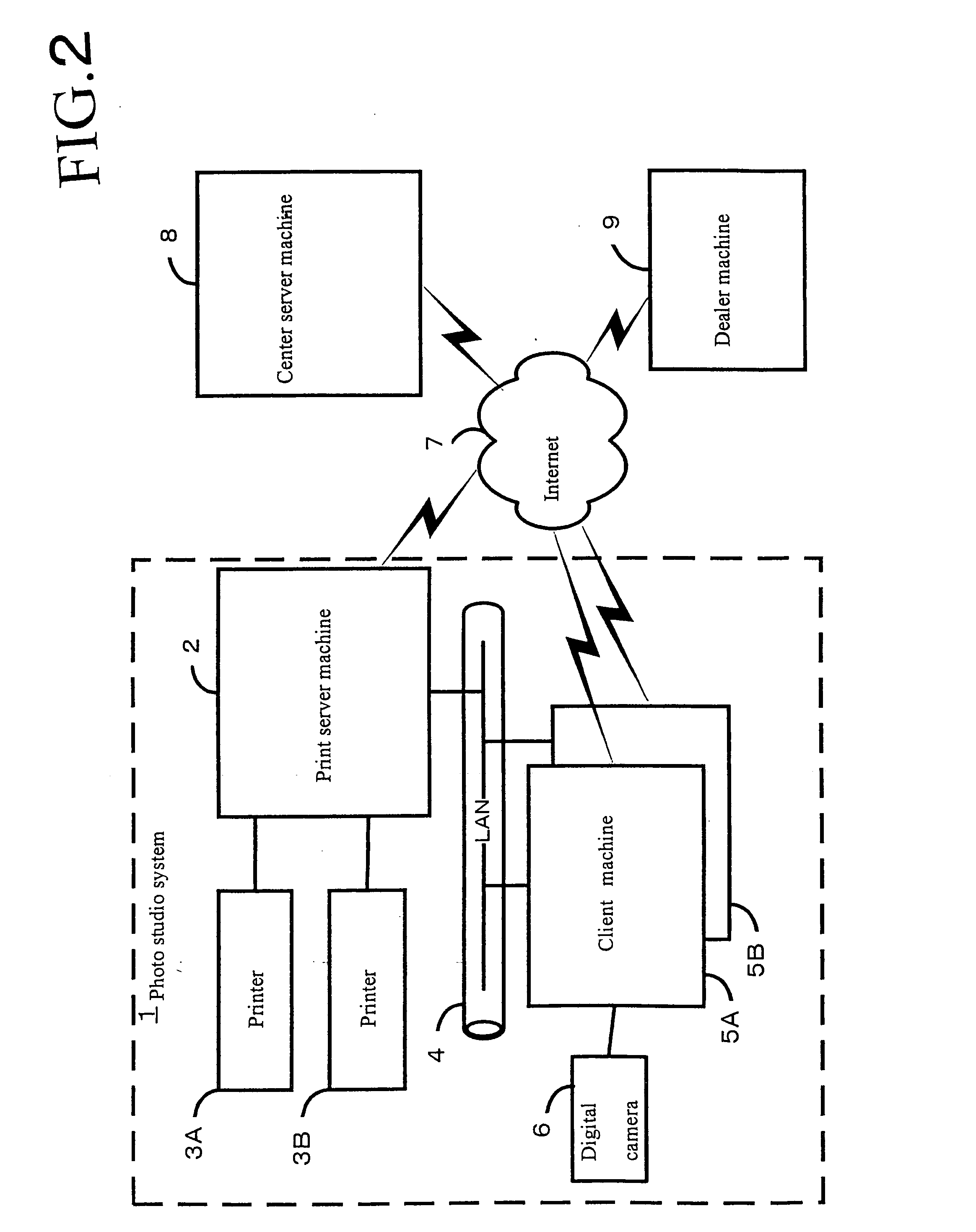

InactiveUS20050036157A1Performs betterSatisfactory coloringDigitally marking record carriersDigital computer detailsICC profileComputer graphics (images)

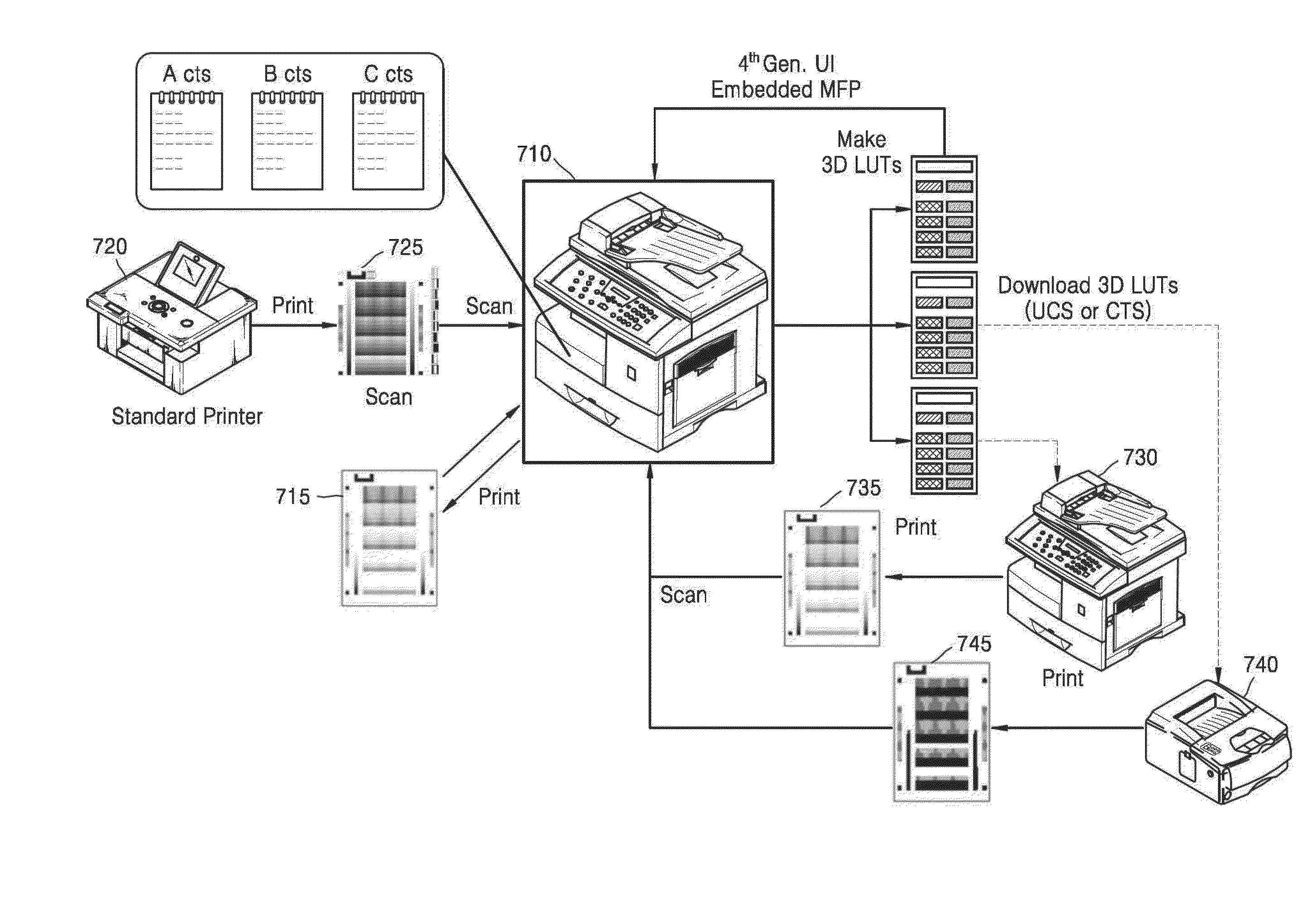

Provided is color printing technology capable of accommodating variation(s) in printer color space(s). User(s) may place test pattern printout(s) 336 and test pattern master sheet(s) 337 next to each other on platen(s) of image scanner(s) 338, and may cause image scanner(s) 338 to scan such printout(s) 336 and master sheet(s) 337 in a single image scanning run. Captured image data output from image scanner(s) 338 may be acquired by print server machine(s) 2 and may be uploaded to center server machine(s) 8. Center server machine(s) 8 is or are such that any difference(s) in color(s) between test pattern printout(s) 336 and master sheet(s) 337 is or are detected based on such uploaded captured image data; furthermore, based on results of such detection, new printer ICC profile(s) is or are created which represents or represent the current color space(s) of printer(s) 3A, 3B being investigated, and corresponding printer ICC profile(s) within printer ICC profile database 330 is or are updated

Owner:SEIKO EPSON CORP

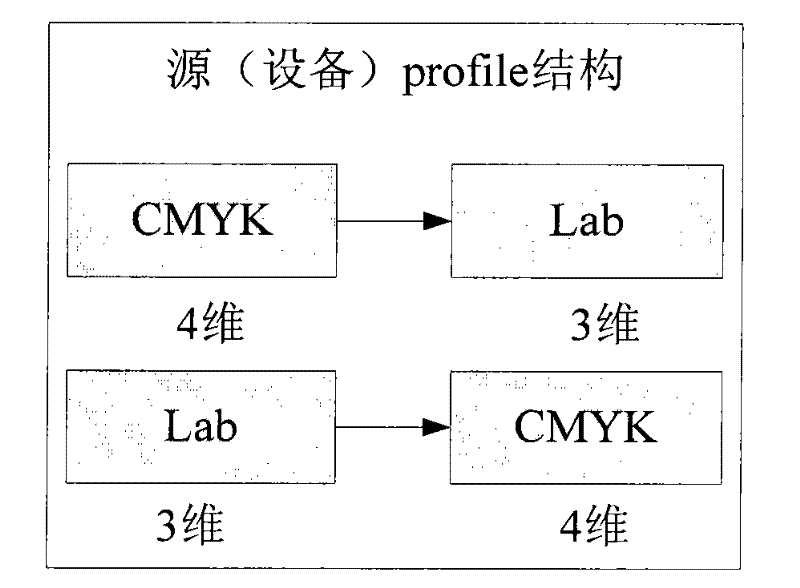

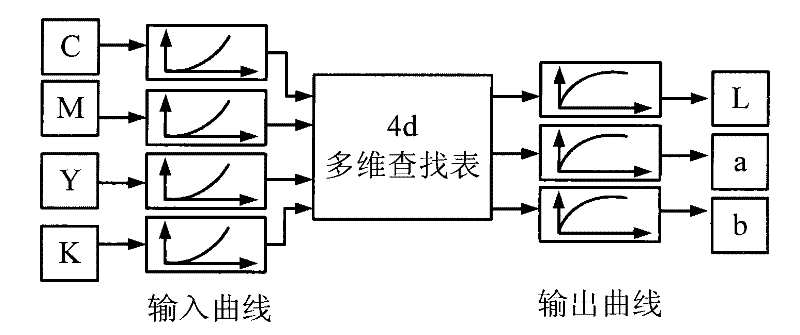

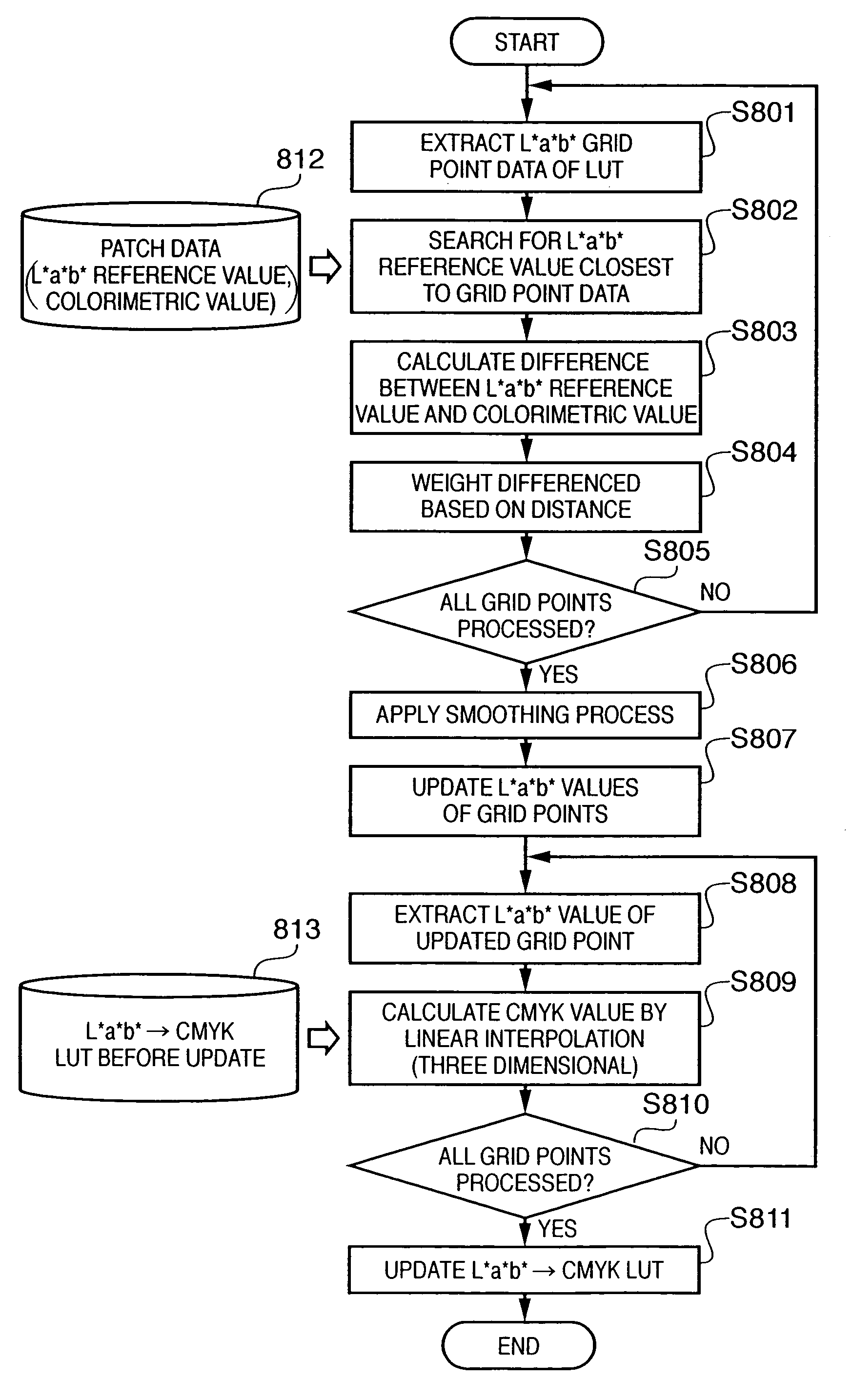

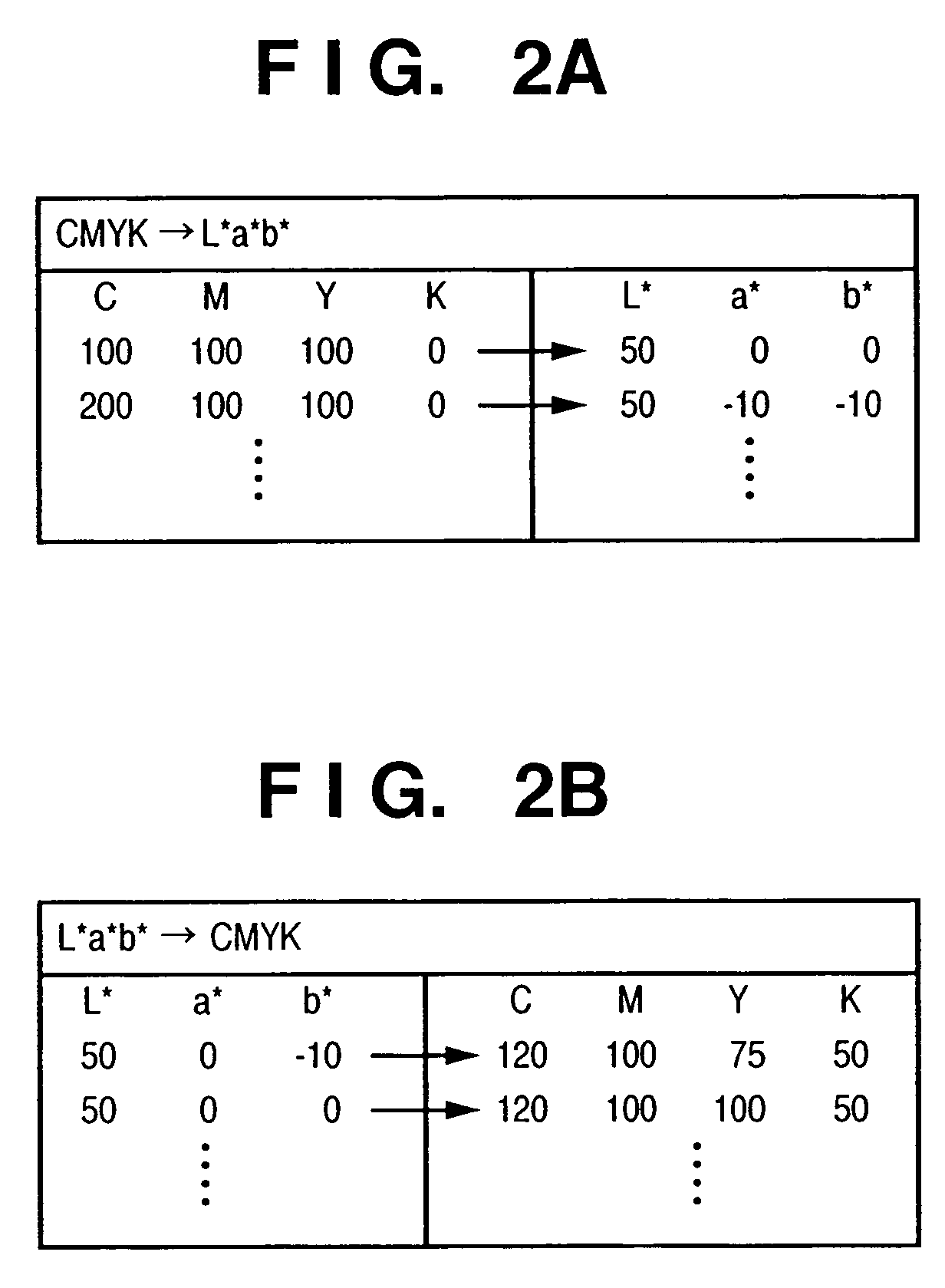

Image processing apparatus and its method

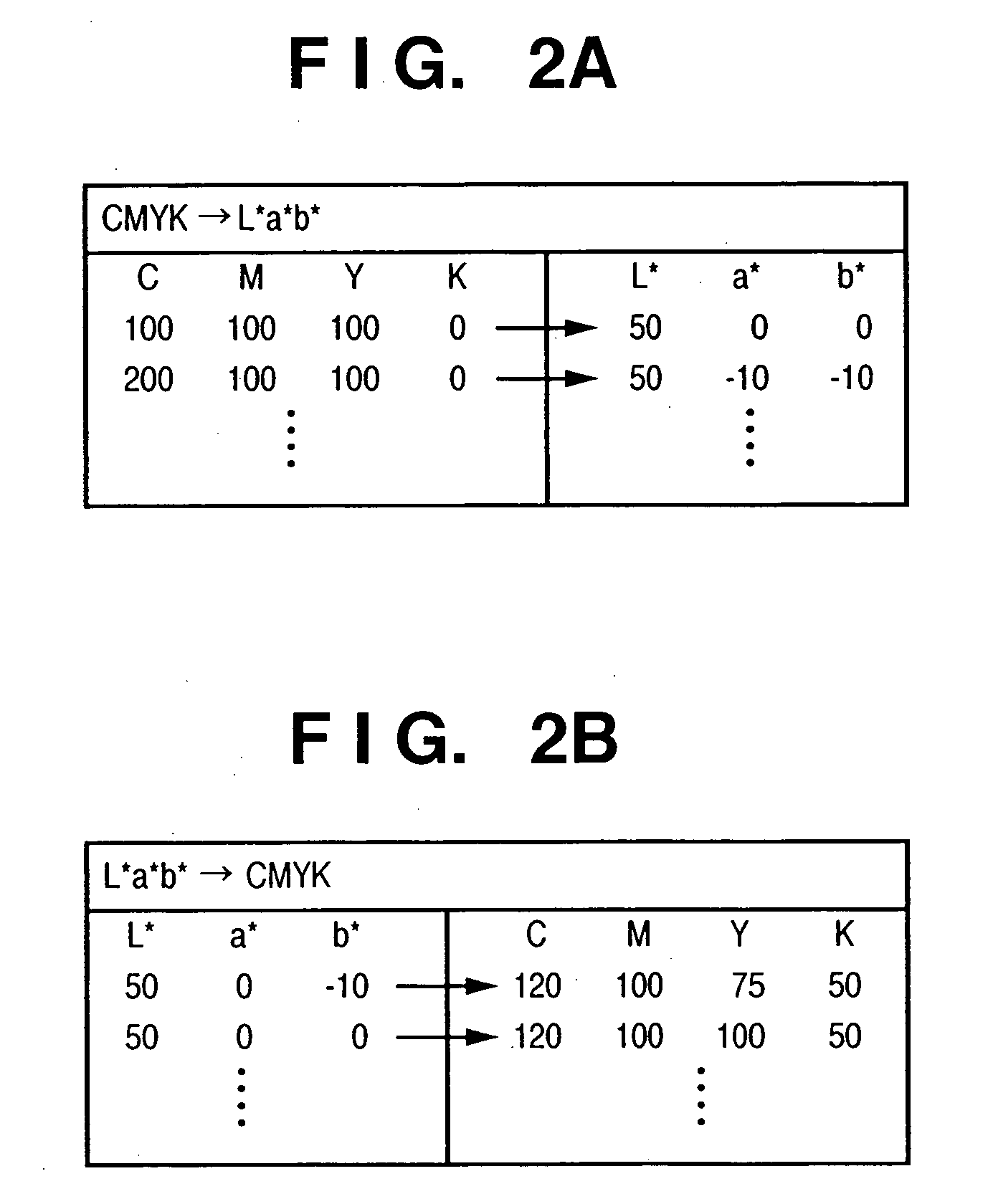

InactiveUS20060007457A1Easy to adjustDigitally marking record carriersTexturing/coloringLab color spaceICC profile

Since many ICC profile generation tools print and measure a large number of color patches and then make profile generation calculations, profile re-generation requires a long time. Hence, patch data are generated, calorimetric values corresponding to the patch data are obtained. Reference values of an Lab color space, which correspond to the patch data, are calculated using a conversion lookup table from a CMYK color space to the Lab color space, which is included in a profile. A conversion lookup table from the Lab color space to the CMYK color space, which is included in the profile, is updated using the calorimetric values and reference values.

Owner:CANON KK

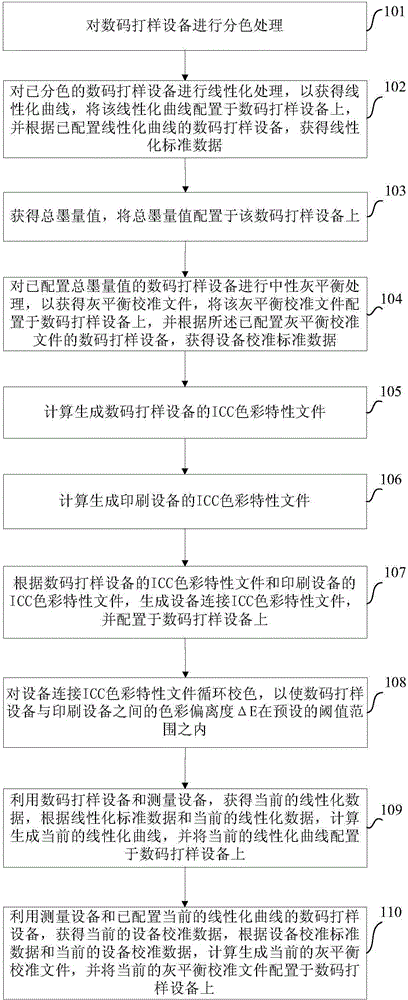

Color correction method for digital sample printing equipment

The invention provides a color correction method for digital sample printing equipment. The method comprises the following steps: generating and configuring a linear curve, total ink and a grey balance calibration file of the digital sample printing equipment in sequence; generating an equipment connection ICC profile according to a generated ICC profile of the digital sample printing equipment and a generated ICC color profile of printing equipment in order to finish primary color correction; and when a trigger condition is satisfied, regenerating a linear curve and a grey balance calibration file in a current sample printing environment by using relevant parameters recorded during primary color correction, and configuring the regenerated linear curve and grey balance calibration file on the sample printing equipment. During secondary color correction of the sample printing equipment, a total ink value and a color separation file do not need to be reconfigured, and color matching between the digital sample printing equipment and the printing equipment does not need to be performed once again, so that color correction flow is simplified, and the color correction time is saved.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

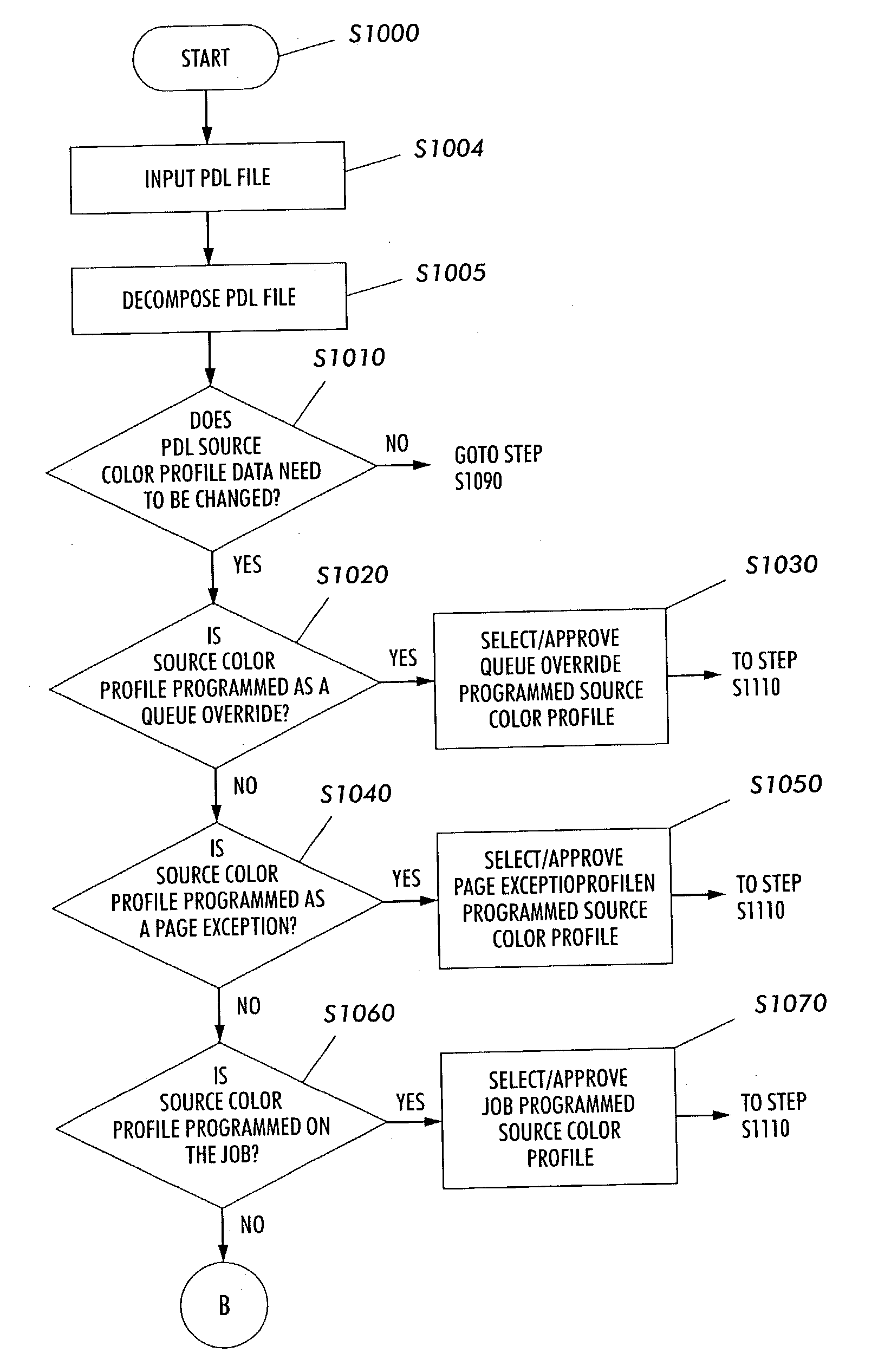

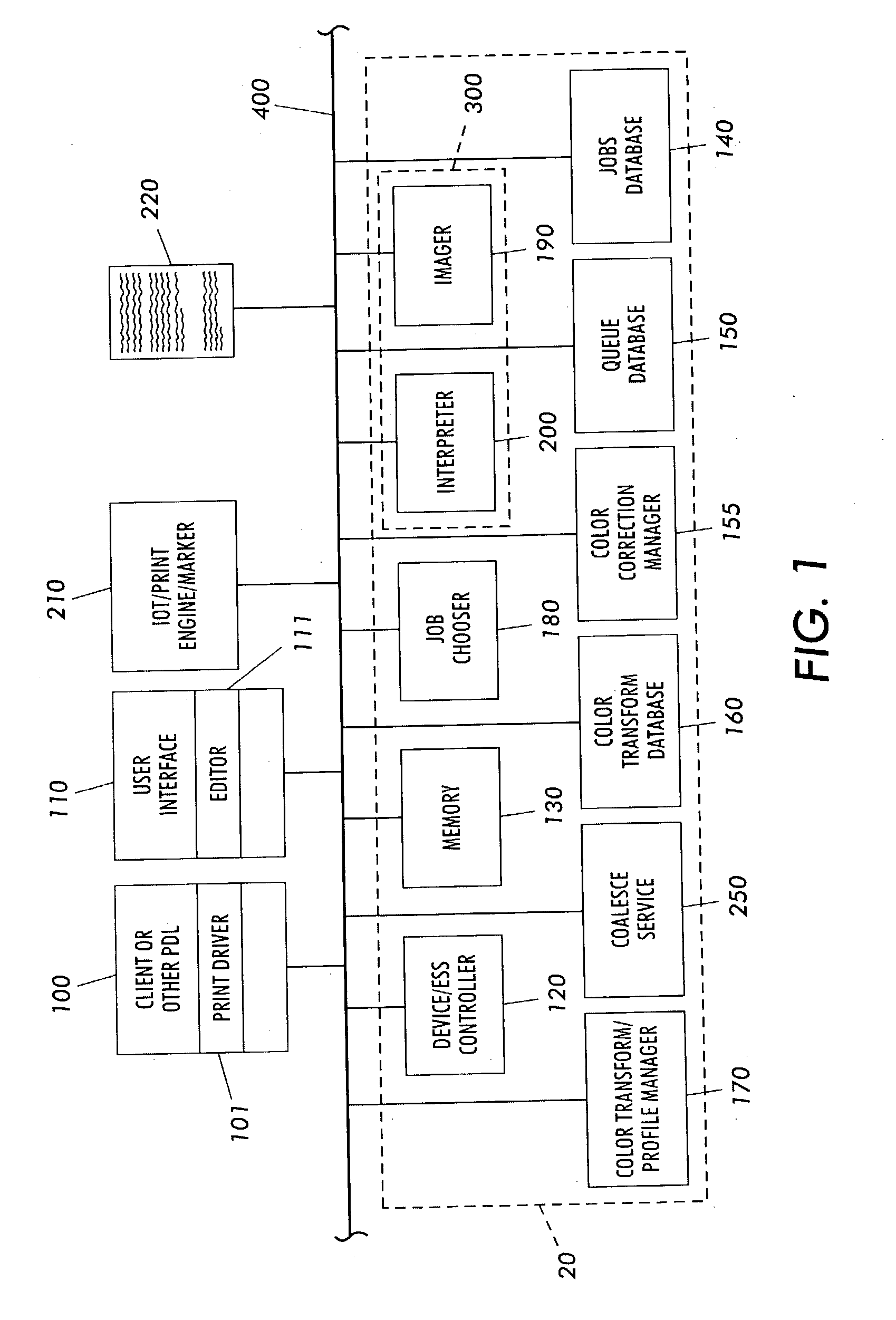

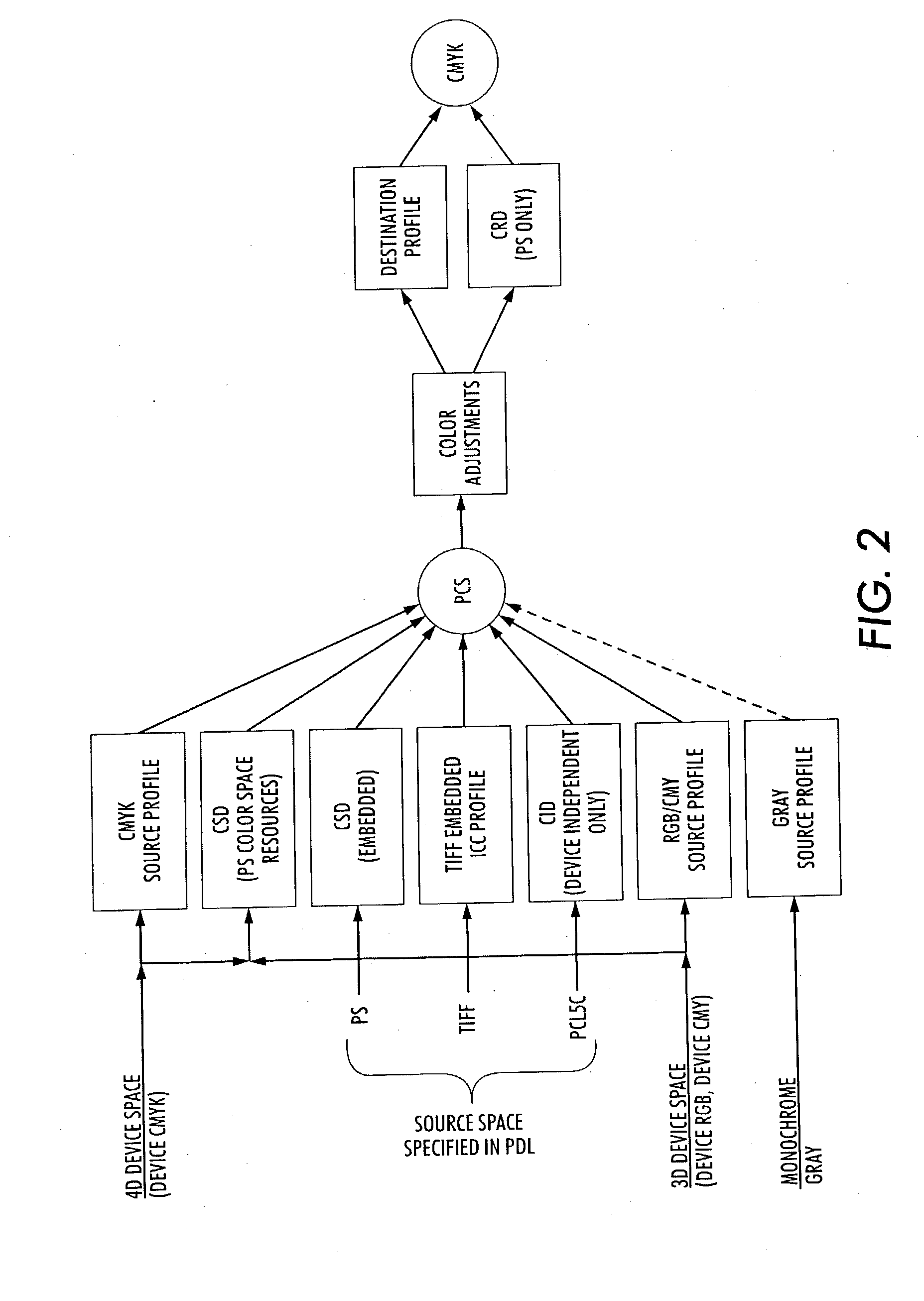

Systems and methods for generating source color space interpretations

Systems and methods are disclosed for enabling page description language (PDL) specified image processing files to be overridden by a user / operator of a digital color copier / printer at raster input scanning time on a job or page basis. A user can specify an input color space profile that is unspecified or when to override a specified input color space profile for desired results. This allows a user to identify treatment of source data in a file, as well as to override embedded ICC profiles. A precedence model is used to determine which source profile to use among a number of possible source profile sources, including queue, job, page and object sources.

Owner:XEROX CORP

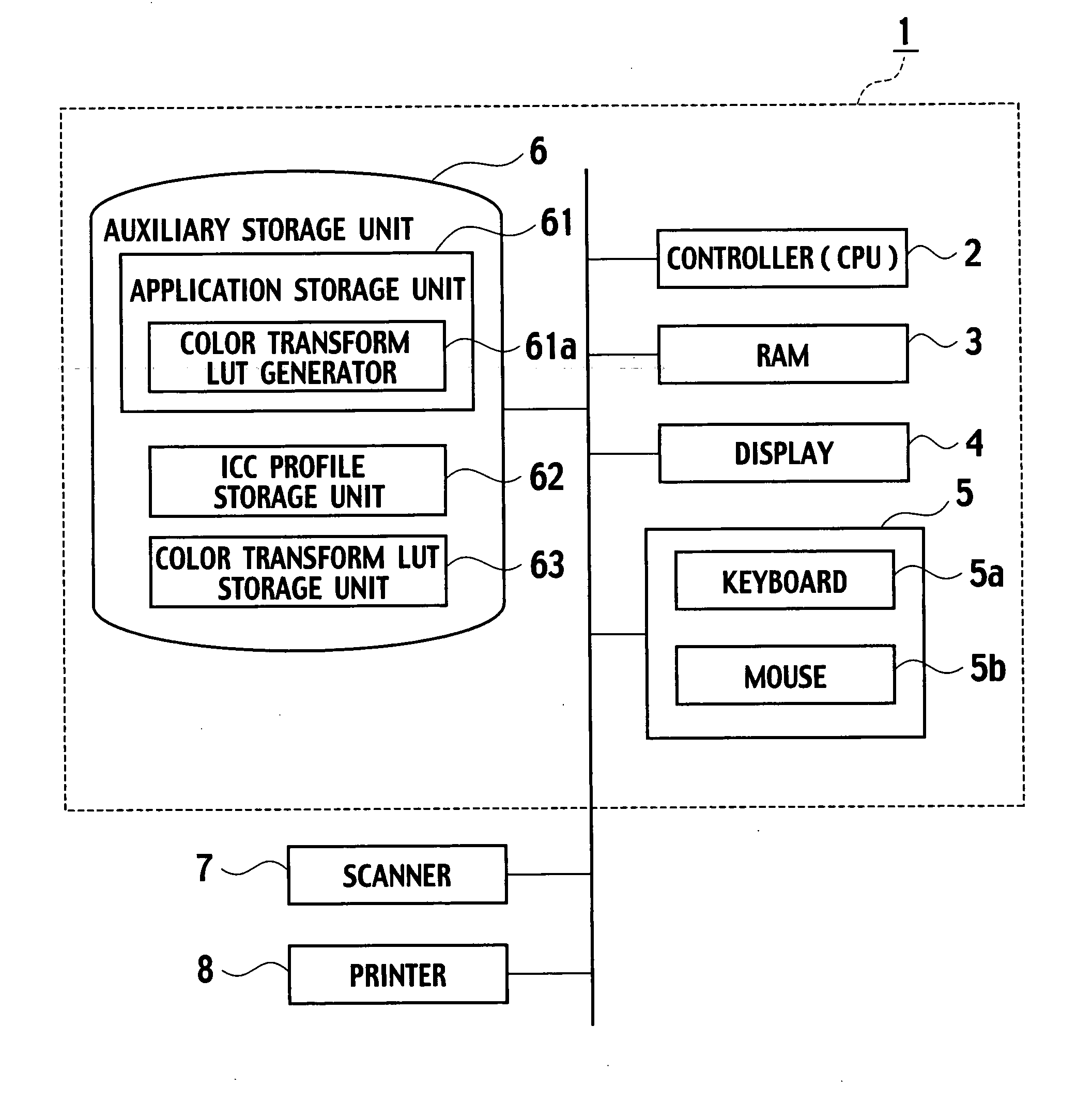

Color processing apparatus and method

Owner:CANON KK

Image processing method and image processing device

InactiveUS20060001892A1High accuracy of color reproductionTrue colorDigitally marking record carriersTexturing/coloringImaging processingICC profile

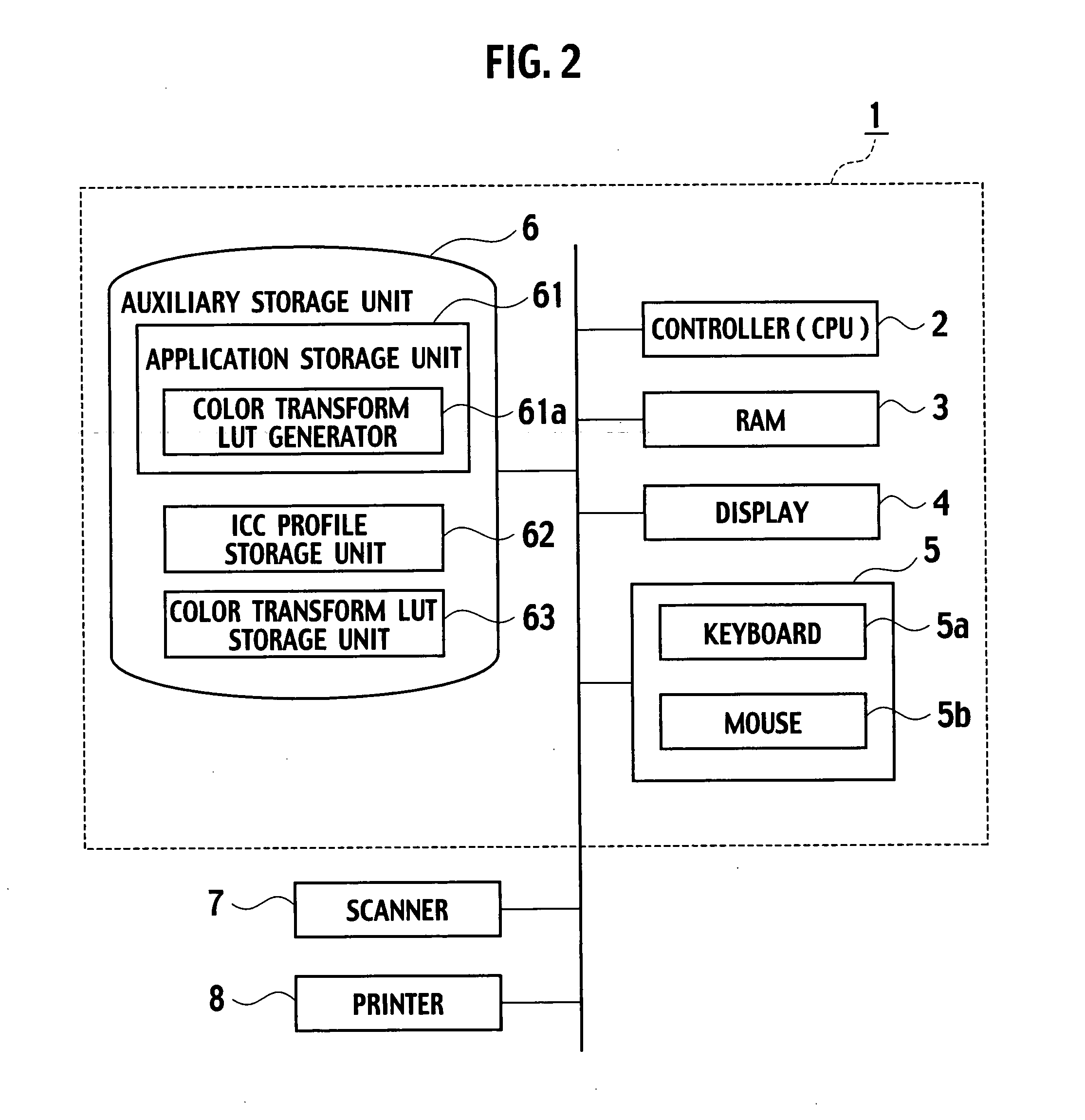

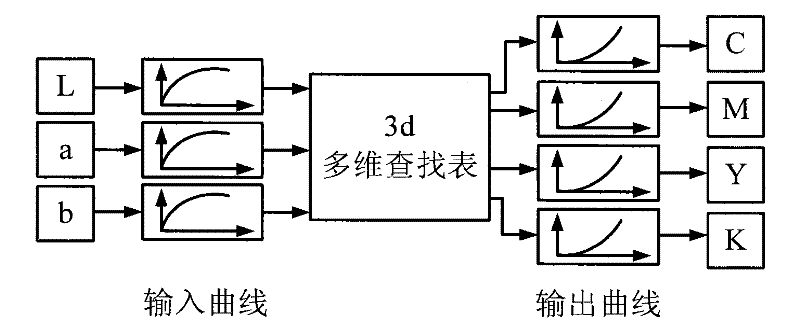

The present invention provides an image processing method and an image processing device for relative accurate color transforming as well as extremely high-speed processing. The image processing method for transforming image data of a scanner RGB color space obtained by a scanner into image data of a printer CMYK color space of a color printer, the image processing method including preparing a color transform look-up table in accordance with an Input ICC profile of the scanner and Output ICC profile of the color printer, and transforming the image data of the scanner RGB color space of the scanner into the image data of the CMYK color space of the color printer by referring to the color transform look-up table. According to the method, the amount of time for the image processing is decreased and the storage volume for storing the color transform look-up table is reduced.

Owner:RISO KAGAKU CORP

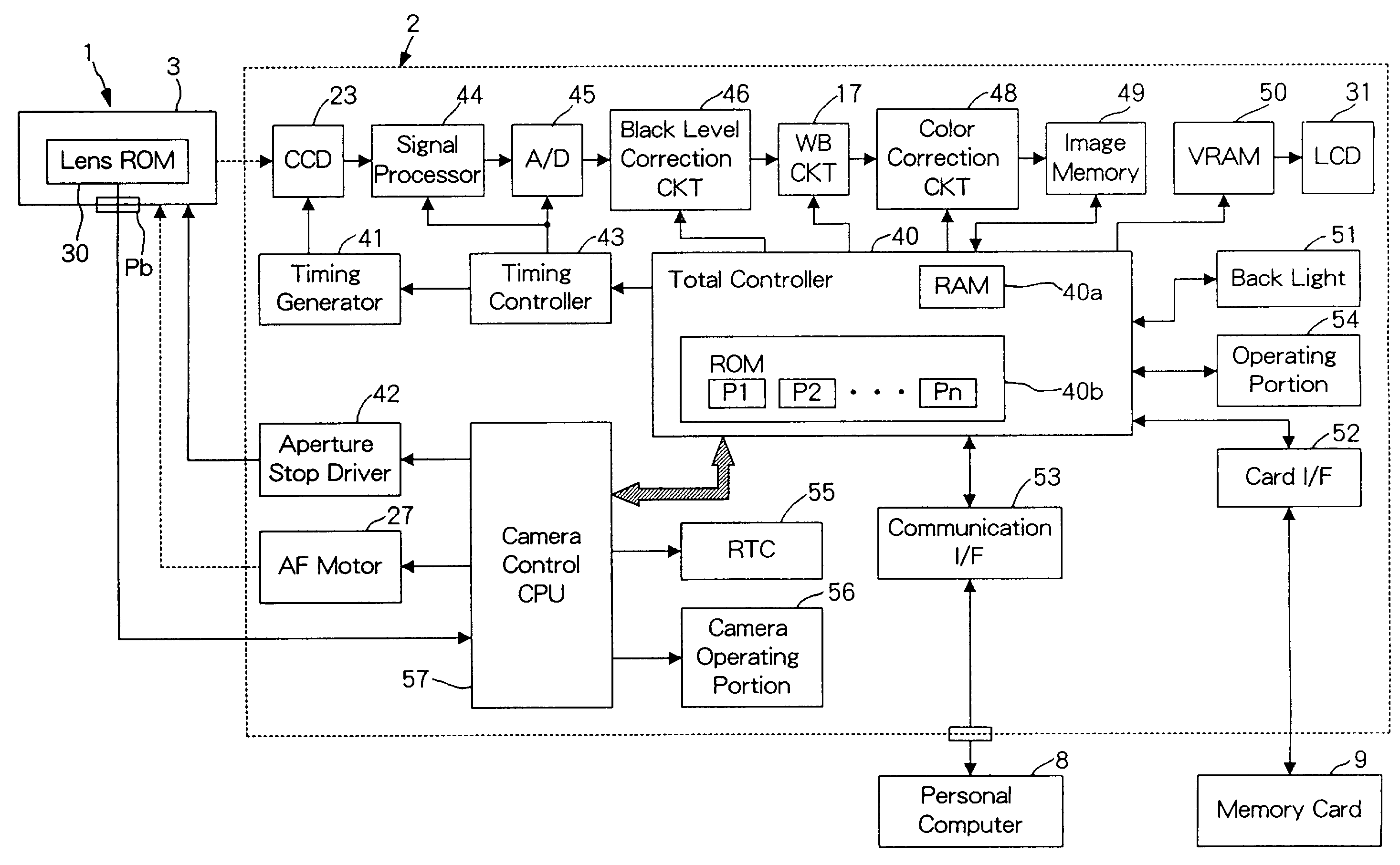

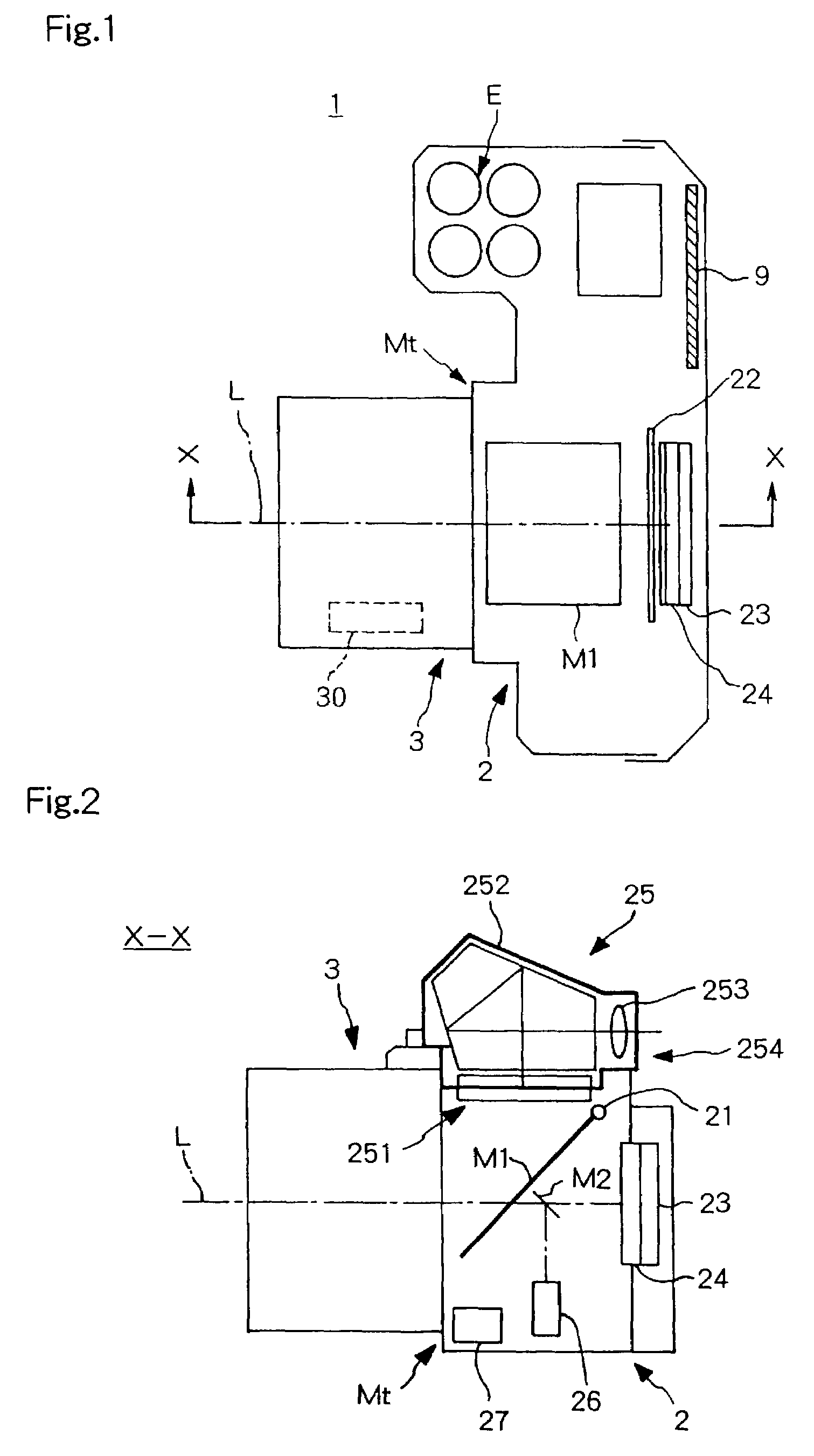

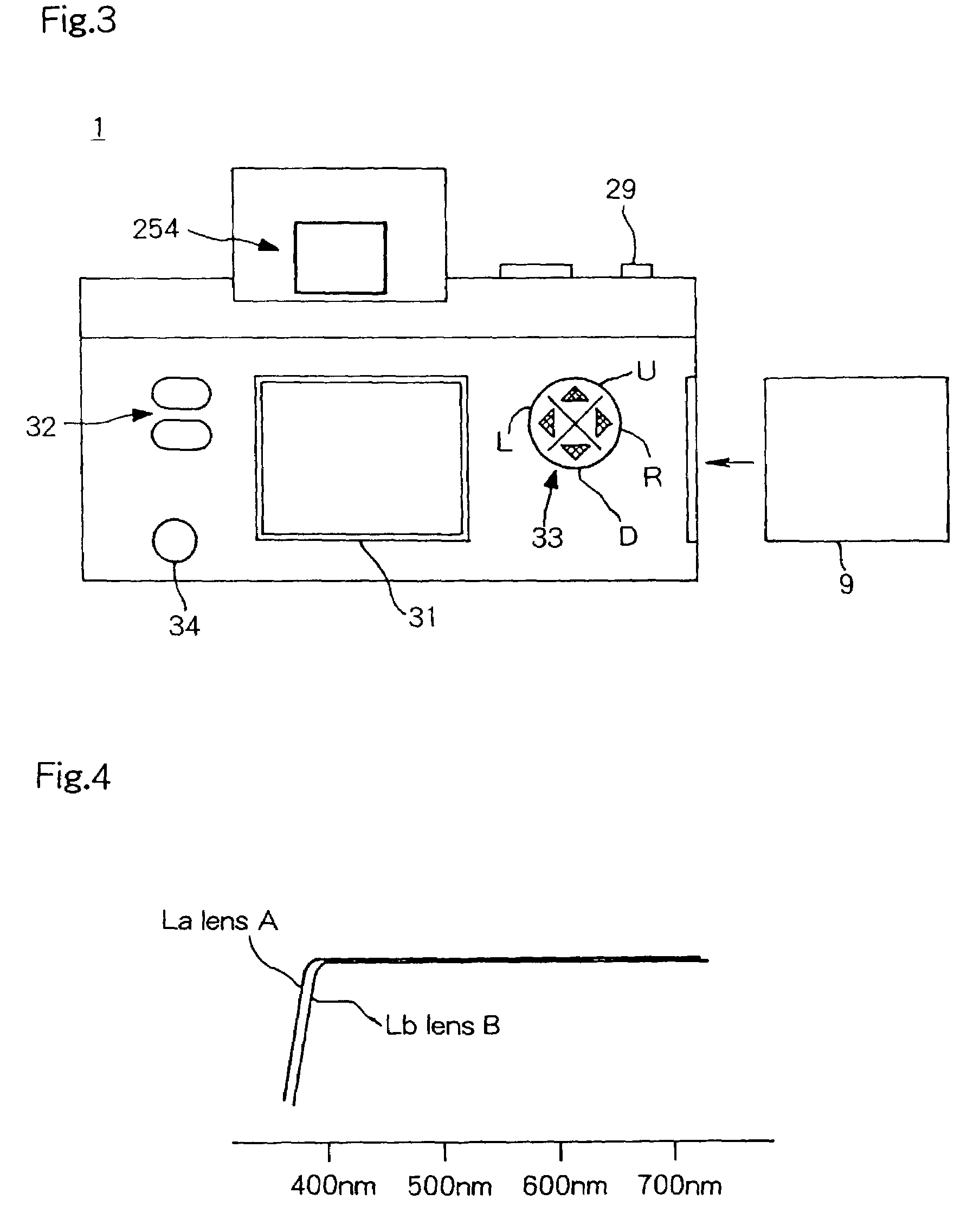

Camera body and interchangeable lens of a digital camera with image-dependent color compensation

InactiveUS7148928B2Avoid associationTelevision system detailsPicture signal generatorsColor compensationCamera lens

In a digital camera 1, an interchangeable lens 3 is attachable to a camera body 2, and a lens ROM 30 is provided in the interchangeable lens 3. In the lens ROM 30, an ICC profile which is color compensate information particular to the interchangeable lens 3 is recorded. When photographing is performed with the interchangeable lens 3 attached, the ICC profile is associated with the obtained image data. Consequently, color compensate information can be set for each kind of interchangeable lens, so that color compensation reflecting the characteristic of the interchangeable lens can be appropriately performed on the image data.

Owner:MINOLTA CO LTD

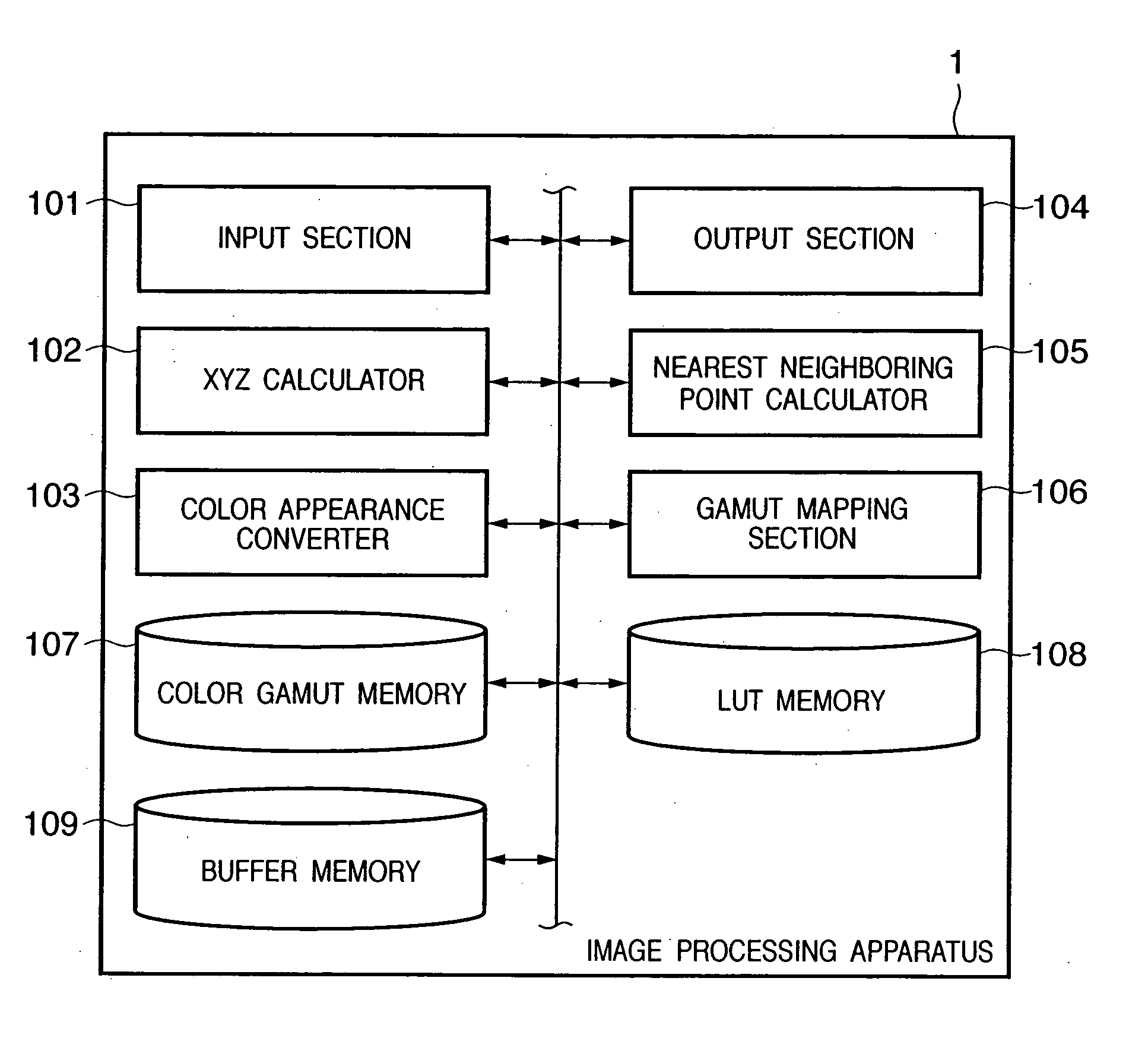

Color processing apparatus and method

It is desired to adopt gamut mapping using a color appearance space in the processing system of an ICC profile. Upon generating an LUT complying with the ICC profile format, when CIEL*a*b* values are converted into CIEXYZ values, and the XYZ values are converted into color appearance space values using color appearance conversion formulas, a point which can be converted and becomes a nearest neighboring point for a point that satisfies a predetermined condition is retrieved, and corresponding color appearance space values are calculated. The obtained color appearance space values are mapped on a predetermined device gamut.

Owner:CANON KK

Terminal and input/output characteristic measurement method and calculation apparatus for display device

InactiveUS6950551B2Easy to measureTelevision system detailsColor signal processing circuitsICC profileMeasuring instrument

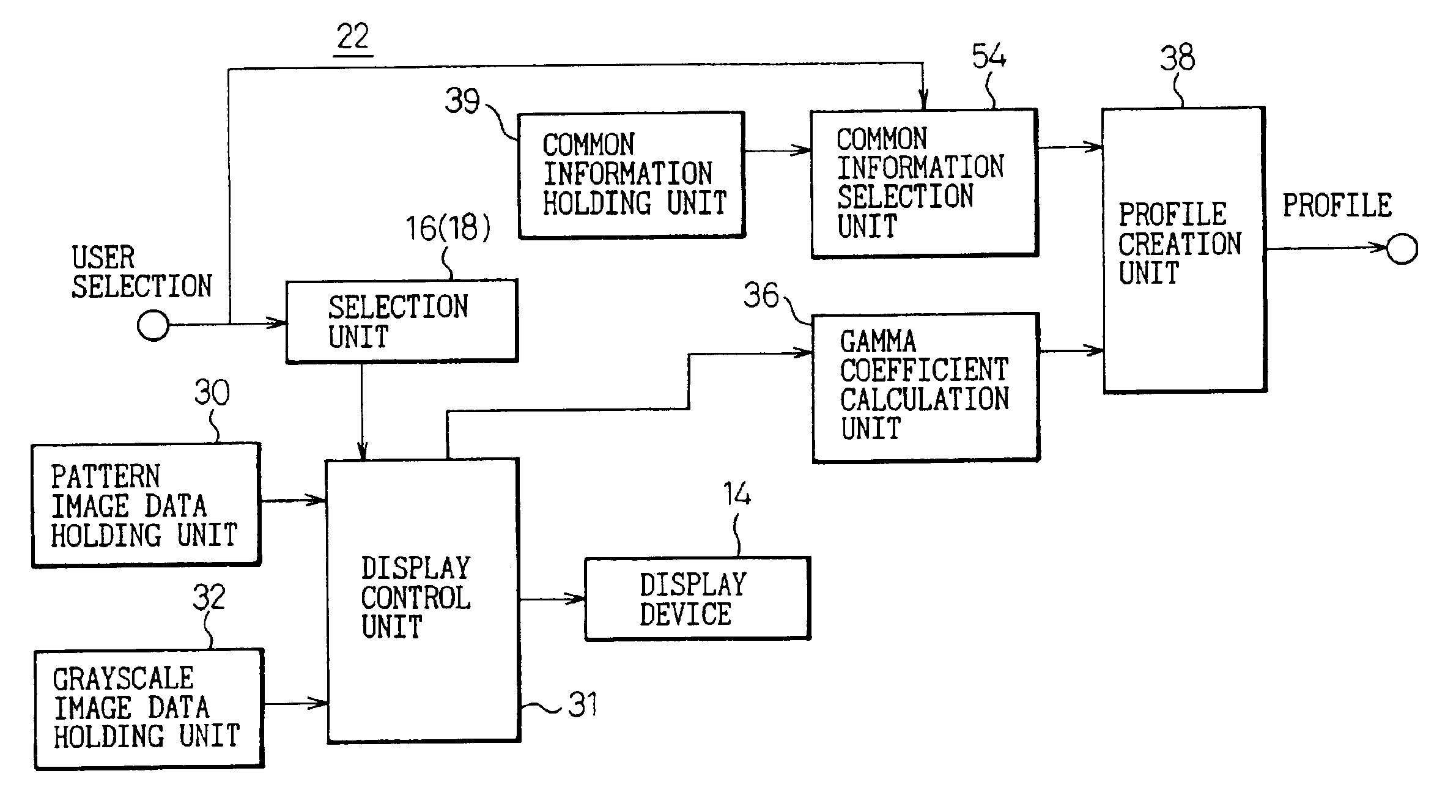

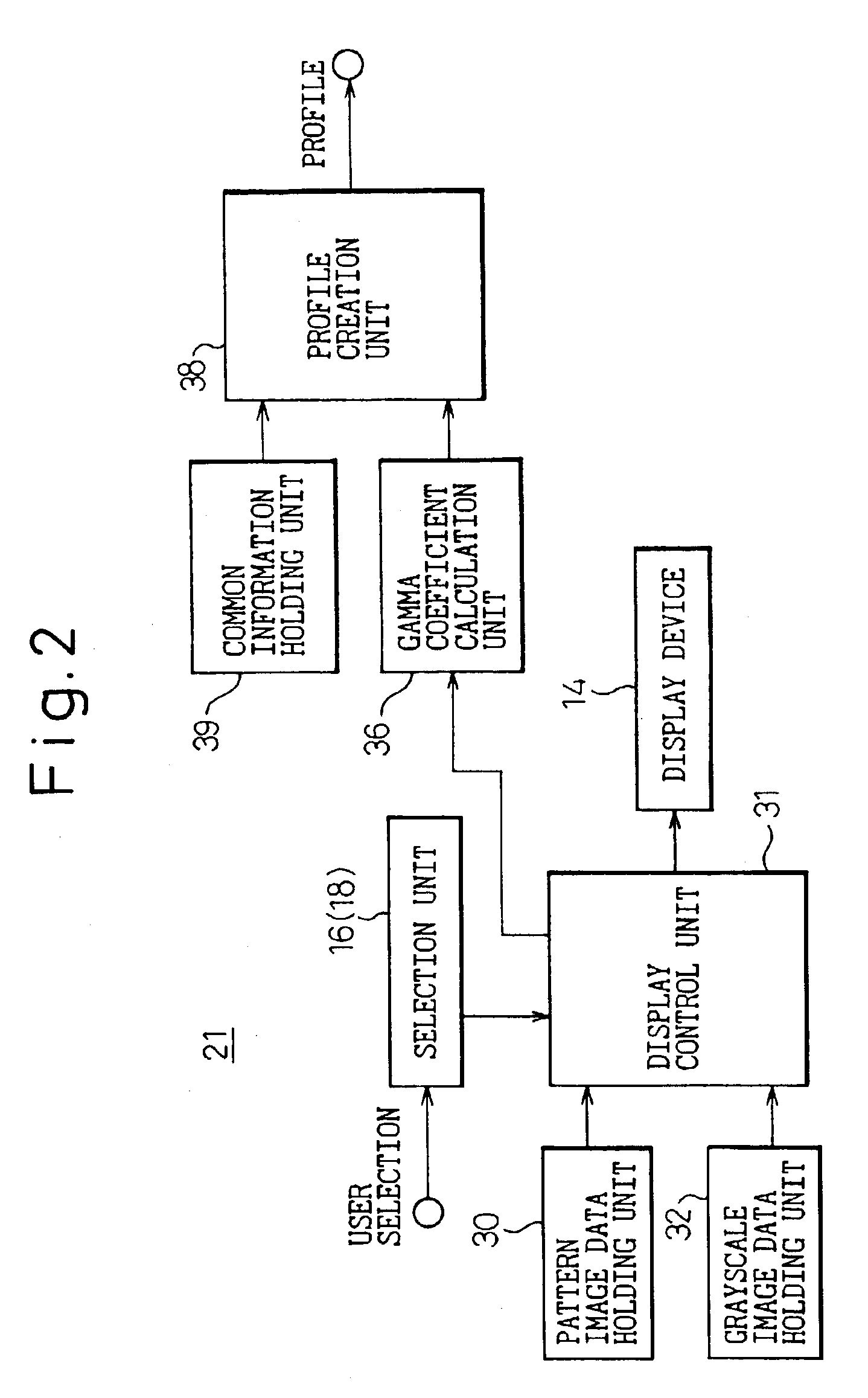

An apparatus for creating an ICC profile in a simple manner without using a specialized measuring instrument. A display control unit reads out a dot pattern image from a pattern image data holding unit and a grayscale pattern image containing a plurality of grayscale patches of gradually varying gray scale from a grayscale image data holding unit, and presents the thus readout images for display on a display device. A user selects the grayscale patch having brightness closest to the brightness of the dot pattern image by operating a selection unit. Based on the selection, a gamma coefficient value is calculated by a gamma coefficient value calculation unit, and based on this gamma coefficient value, a profile creation unit modifies the ICC profile held in a common information holding unit and thus creates a customized ICC profile.

Owner:FUJITSU LTD

Image processing apparatus and its method, and control method

InactiveUS20080068630A1Accurate descriptionDigitally marking record carriersVisual presentation using printersImaging processingICC profile

An ICC profile includes brief gloss information indicating glossy / matte attribute as attribute information, however, gloss matching cannot be performed with the 2 options. In a case where embedding of glossiness information into the ICC profile is designated, glossiness information is obtained from a color chart placed on an original plate of a color copier, and the obtained glossiness information is described in a private tag of the ICC profile.

Owner:CANON KK

Method and system for generating international color consortium profile file

InactiveCN102238297AReduce noise interferenceImprove smoothnessImage enhancementPictoral communicationPattern recognitionICC profile

The invention provides a method and a system for generating an international color consortium (ICC) Profile file in the color management of printing and digital proofing. The method comprises the following steps of: optimizing a Lab value corresponding to a Neugebauer base color according to the measurement data of a color target diagram and a Neugebauer equation; filtering the measurement data of the color target diagram according to the optimized Lab value corresponding to the Neugebauer base color; and generating the ICC Profile file according to the filtered measurement data. Correspondingly, the invention provides the system for generating the ICC Profile file. The system comprises an optimization unit and a filtering unit. In the method and the system, the Lab value corresponding tothe Neugebauer base color in the color target diagram is optimized by utilizing a Neugebauer equation model, and the measured Lab values of all color blocks are filtered by utilizing the optimized Lab value corresponding to the Neugebauer base color, thereby reducing noise interference in the measurement of the color target diagram and improving the smoothness and accuracy of the measurement dataand the quality of the ICC Profile file.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Print controlling terminal and method for compensating colors

ActiveUS20120038938A1Digitally marking record carriersDigital computer detailsICC profileColor transformation

A present color compensating method includes receiving selection of an input ICC profile and an output ICC profile, receiving selection of a plurality of color rendering intents to be applied to an ICC profile, generating a color conversion table using the selected input ICC profile, the selected output profile, and the selected plurality of color rendering intents, and generating print data using the generated color conversion table.

Owner:HEWLETT PACKARD DEV CO LP

Image processing apparatus and its method

InactiveUS8072658B2Easy to adjustDigitally marking record carriersTexturing/coloringLab color spaceICC profile

Since many ICC profile generation tools print and measure a large number of color patches and then make profile generation calculations, profile re-generation requires a long time. Hence, patch data are generated, calorimetric values corresponding to the patch data are obtained. Reference values of an Lab color space, which correspond to the patch data, are calculated using a conversion lookup table from a CMYK color space to the Lab color space, which is included in a profile. A conversion lookup table from the Lab color space to the CMYK color space, which is included in the profile, is updated using the calorimetric values and reference values.

Owner:CANON KK

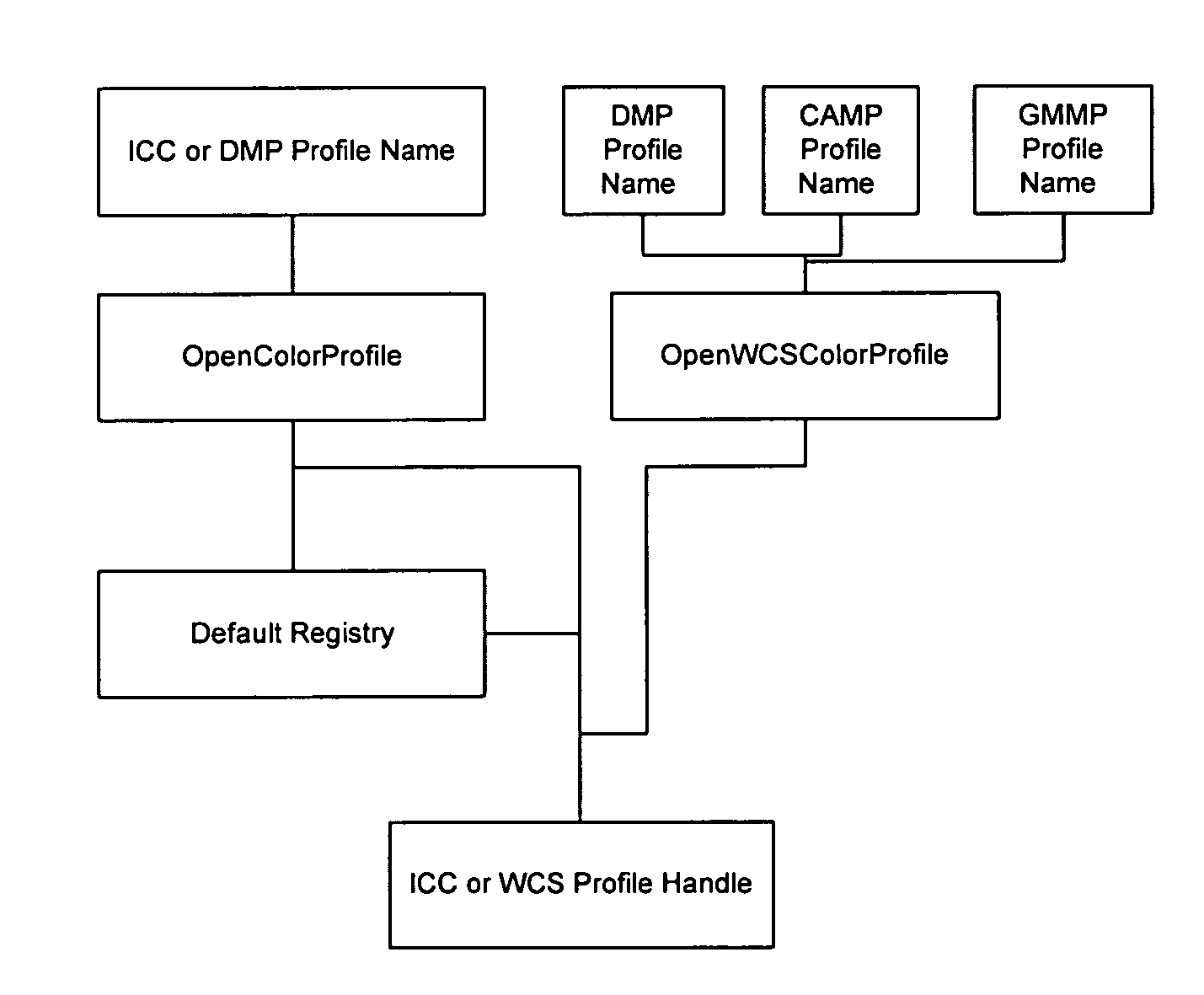

Gamut mapping and rendering intent management system

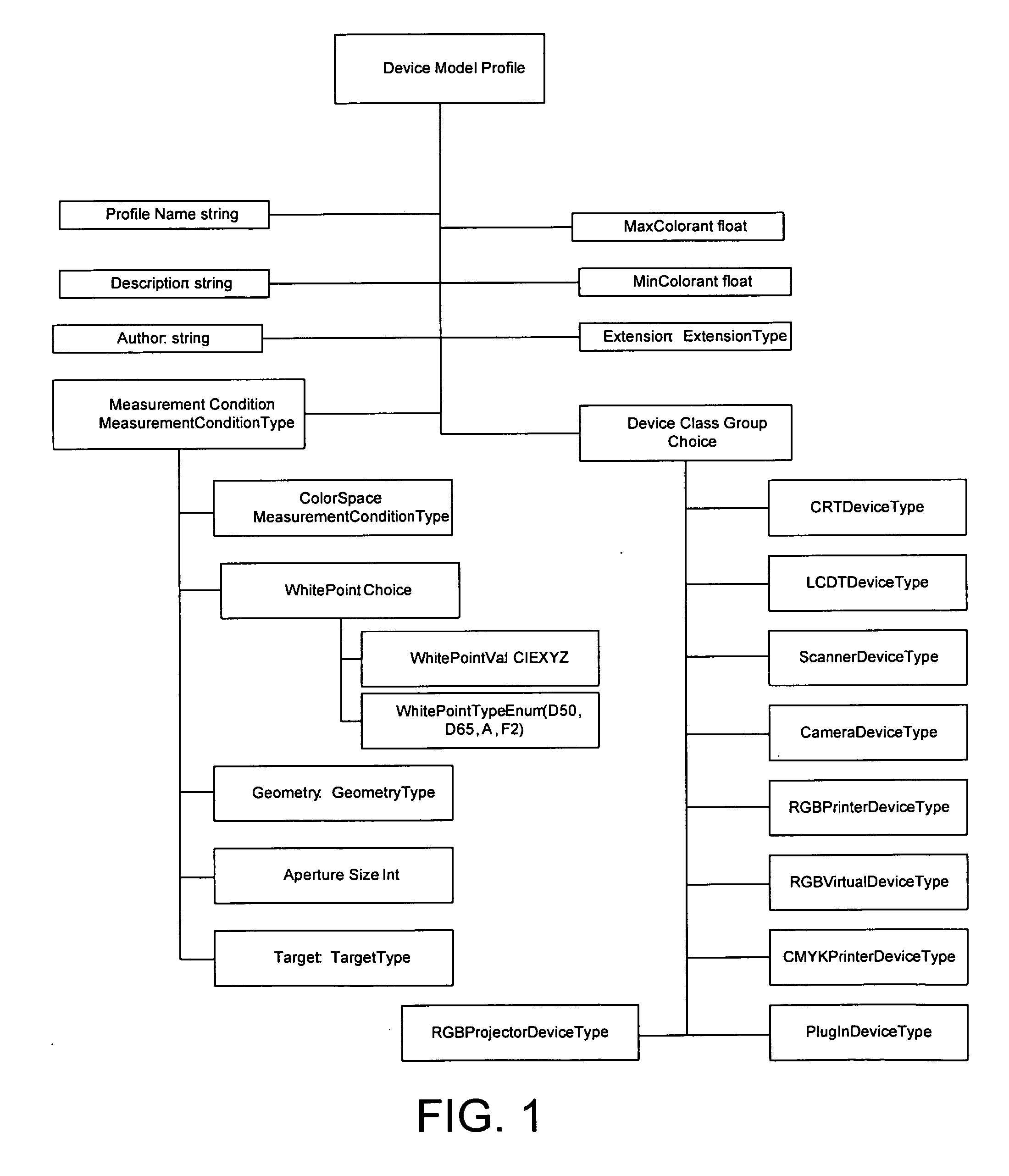

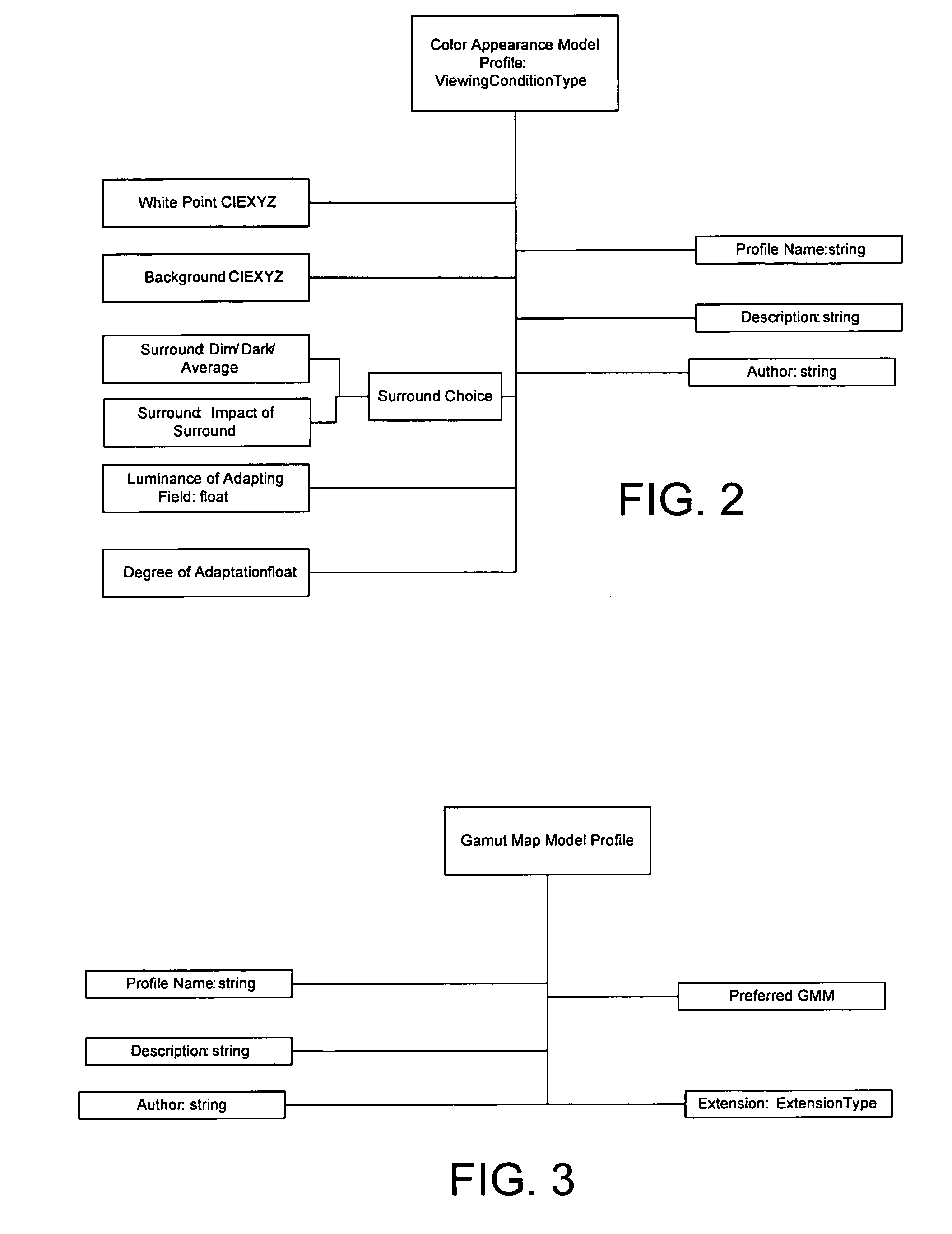

A system and method for selectively setting gamut map model defaults in a color management system is disclosed for transforming colors from a first color space to a second color space. The method includes the steps of comprises determining the profile associated with the second color space from one of an ICC profile, a device model profile and a system default profile; associating a color appearance profile and a gamut mapping profile based on the profile; and selecting at least one of the color appearance and gamut mapping profiles based on the profile associated with the second color space.

Owner:MICROSOFT TECH LICENSING LLC

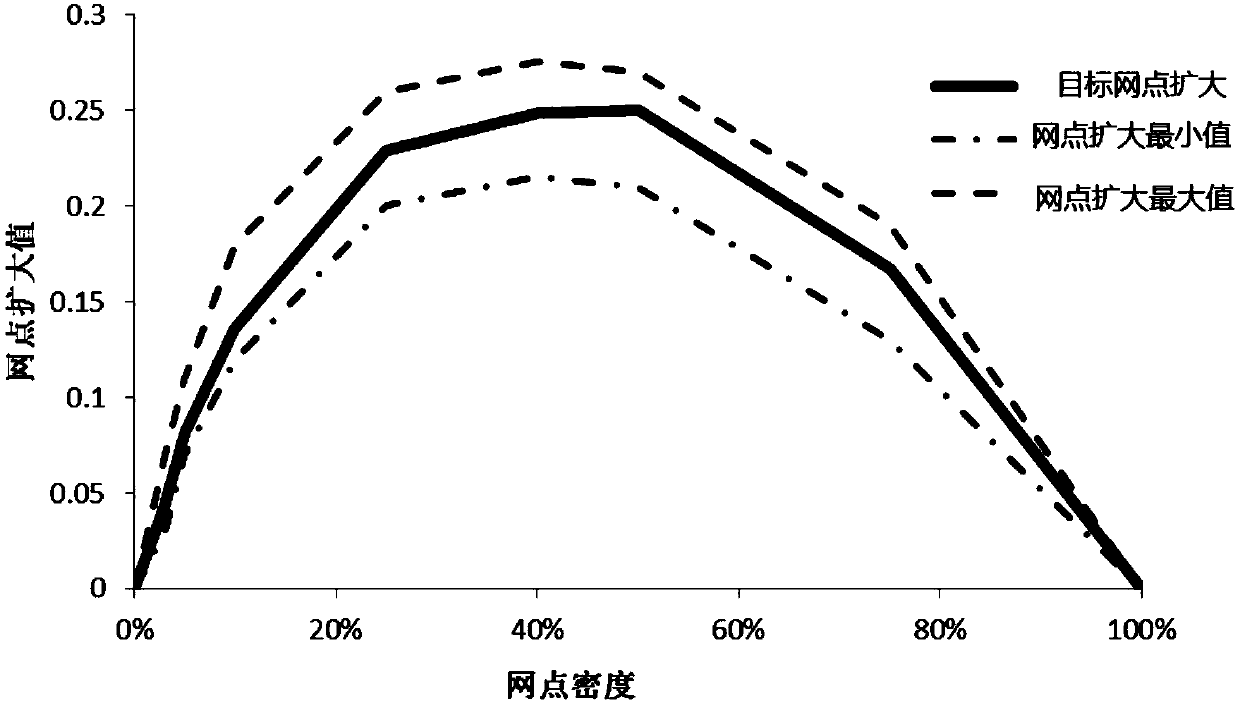

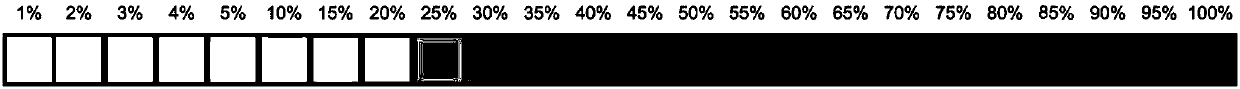

Method for controlling quality of intaglio printing special color and halftone images

InactiveCN107796773AAdd control pointsEasy to operateOptically investigating flaws/contaminationColor/spectral properties measurementsICC profileEngraving

The invention relates to a method for controlling the quality of intaglio printing special color and halftone images. The method comprises the following steps: (1) making a single-color-gradation color-modulating card and setting standard Min DG and Max DG for a typical website; (2) performing printing test on the single-color-gradation color-modulating card on a printing machine; (3) calculatingthe expanding value of the corresponding website by a Murray-Davis formula, guaranteeing that the the expanding value is between the Min DG and the Max DG to obtain a TVI curve and a color reduction curve and making a standard sample of a monochromatic pattern to enable the website expanding value of the typical website to be between Min DG and Max DG; and (4) obtaining an international color consortium (ICC) color characteristic file and a standard reduction curve according to the standard sample, performing plate making and making a draft. By the method, the image can be directly engraved onthe printing plate during engraving, other cost is not needed, the judgment is simple, and the accuracy and the standard of quality control of the intaglio printing special color and halftone image are improved.

Owner:上海紫江彩印包装有限公司

Generating a look-up table for use in color processing

InactiveUS7983479B2High quality imagingDigitally marking record carriersDigital computer detailsGamutICC profile

It is desired to adopt gamut mapping using a color appearance space in the processing system of an ICC profile. Upon generating an LUT complying with the ICC profile format, a grid point outside of the visible region on the CIELAB space is moved into the visible region. The Lab values of the grid point are converted into XYZ values, which undergo color appearance conversion to acquire color appearance values. The acquired color appearance values are mapped on the color gamut of a predetermined device.

Owner:CANON KK

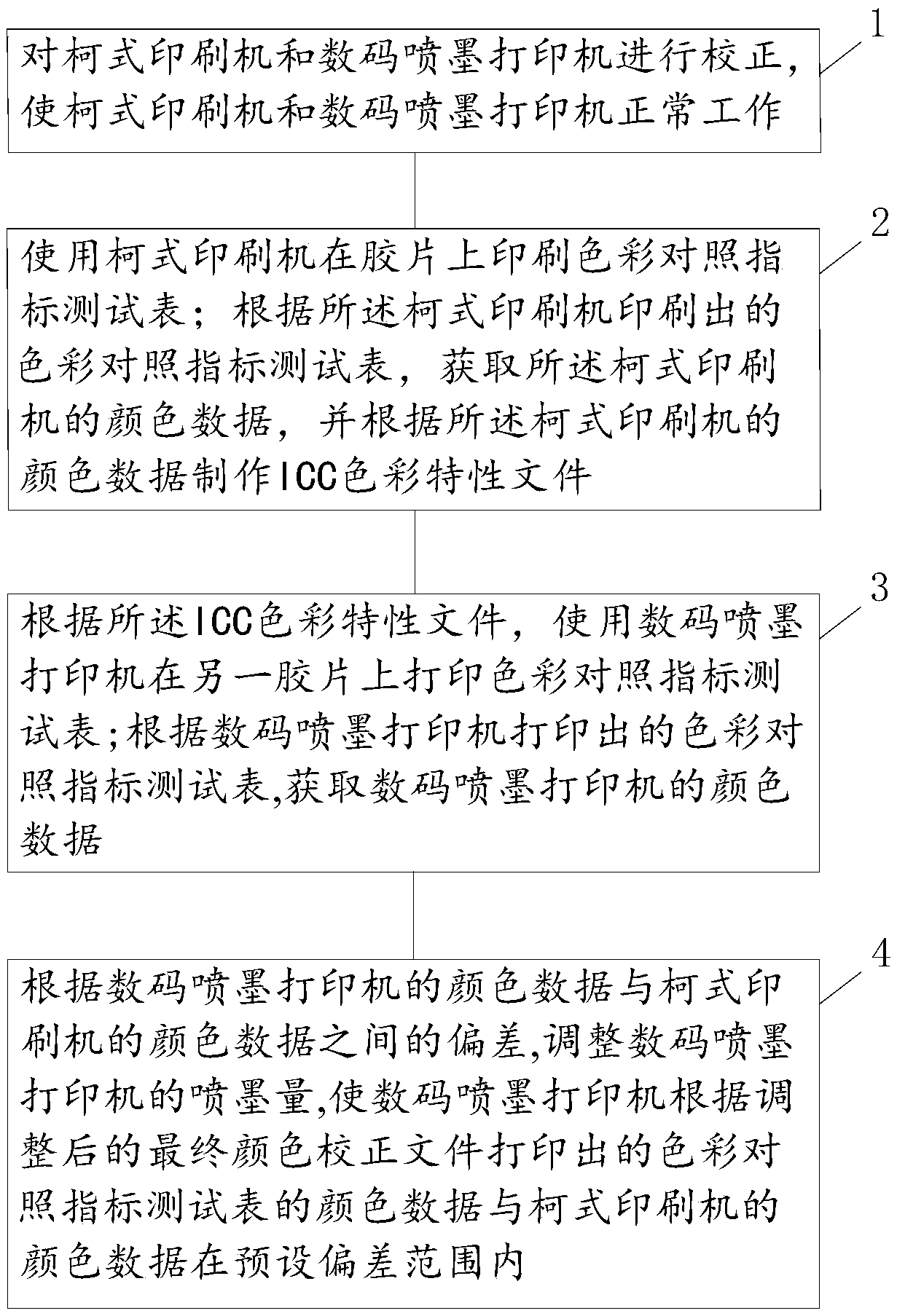

Manufacturing method of film sample manuscript

InactiveCN109177556AHighly simulated printing effectShorten production timeDuplicating/marking methodsOther printing apparatusIndex testICC profile

The invention relates to the field of film printing, in particular to a manufacturing method of a film sample manuscript. According to the key points, the manufacturing method of the film sample manuscript comprises the following steps that 1, an offset printing machine and a digital ink-jet printer are revised; 2, a color contrast index testing chart is printed by using the offset printing machine, color data of the offset printing machine is obtained, and an ICC color specific document is manufactured; 3, another color contrast index testing chart is printed on another film by using the digital ink-jet printer according to the ICC color specific document, and color data of the digital ink-jet printer is obtained; and 4, the ink-jet amount of the digital ink-jet printer is adjusted according to a deviation between the color data of the digital ink-jet printer and the color data of the offset printing machine, so that the digital ink-jet printer revises the color data of the color contrast index testing chart printed by the document and the color data of the offset printing machine are within a preset deviation range according to a final adjusted color. Compared with a traditionalproofing, manufacturing method of the film sample manuscript is more convenient and the speed is faster.

Owner:DONGGUAN FUCAI PACKAGING PROD

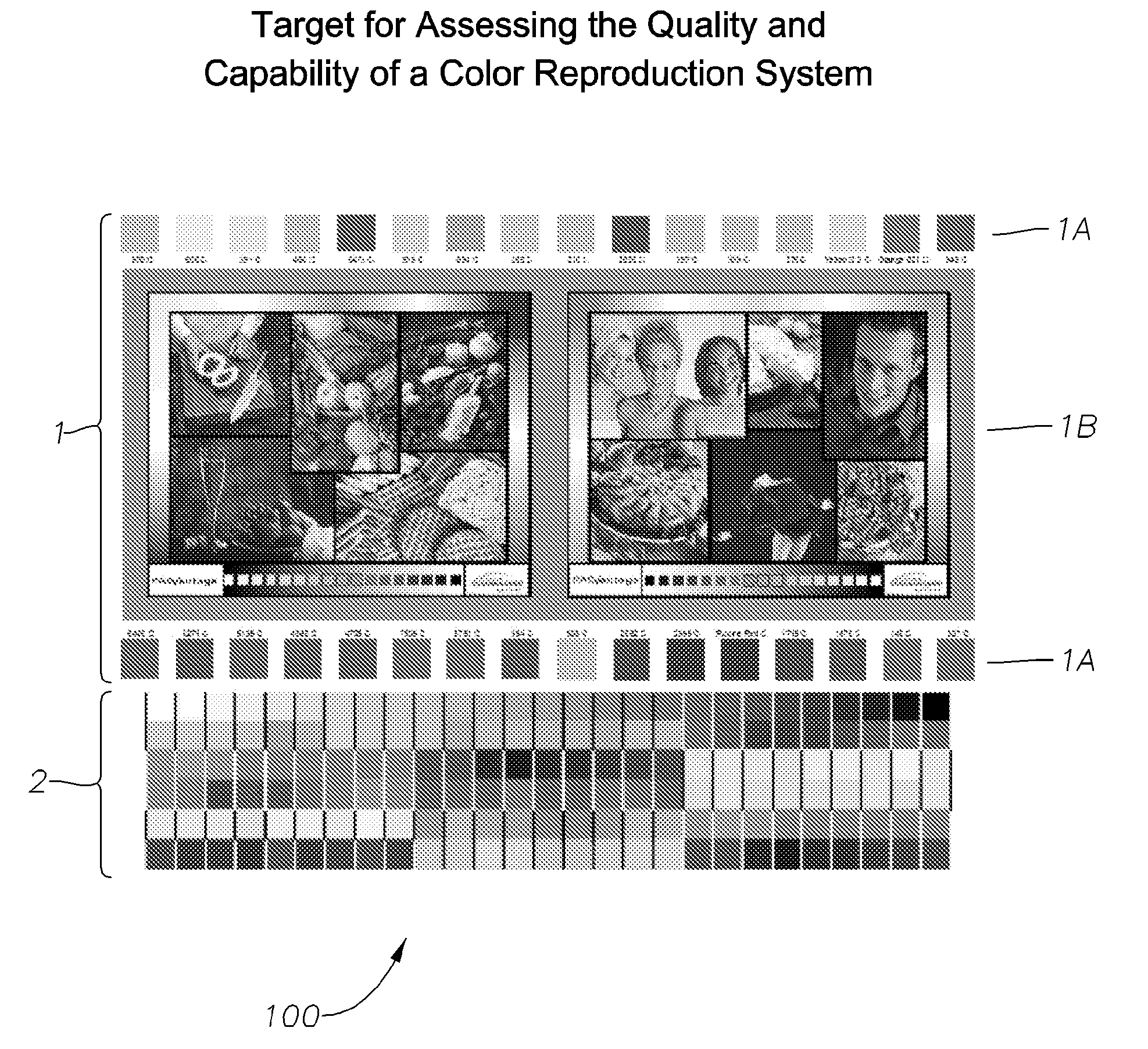

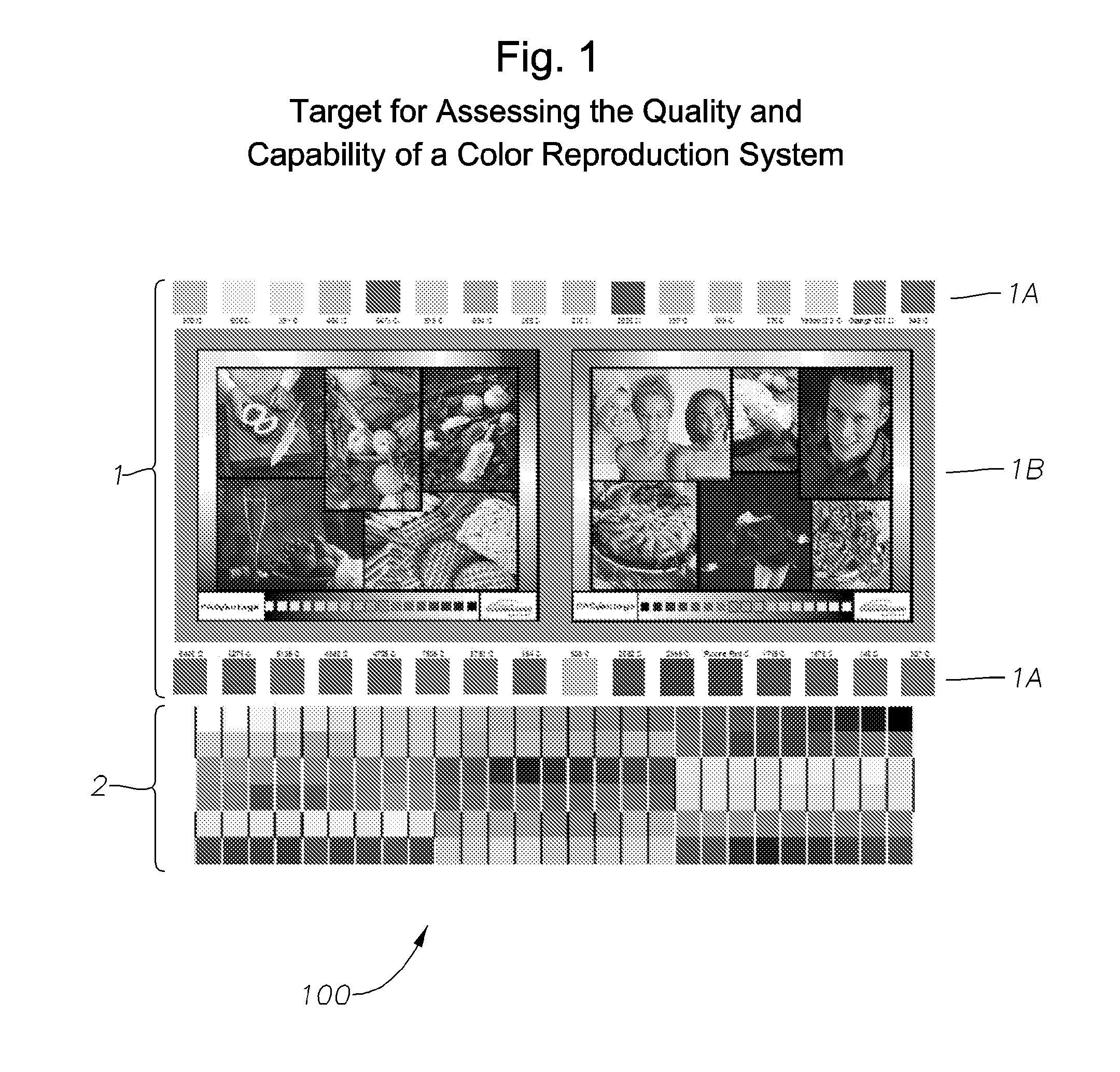

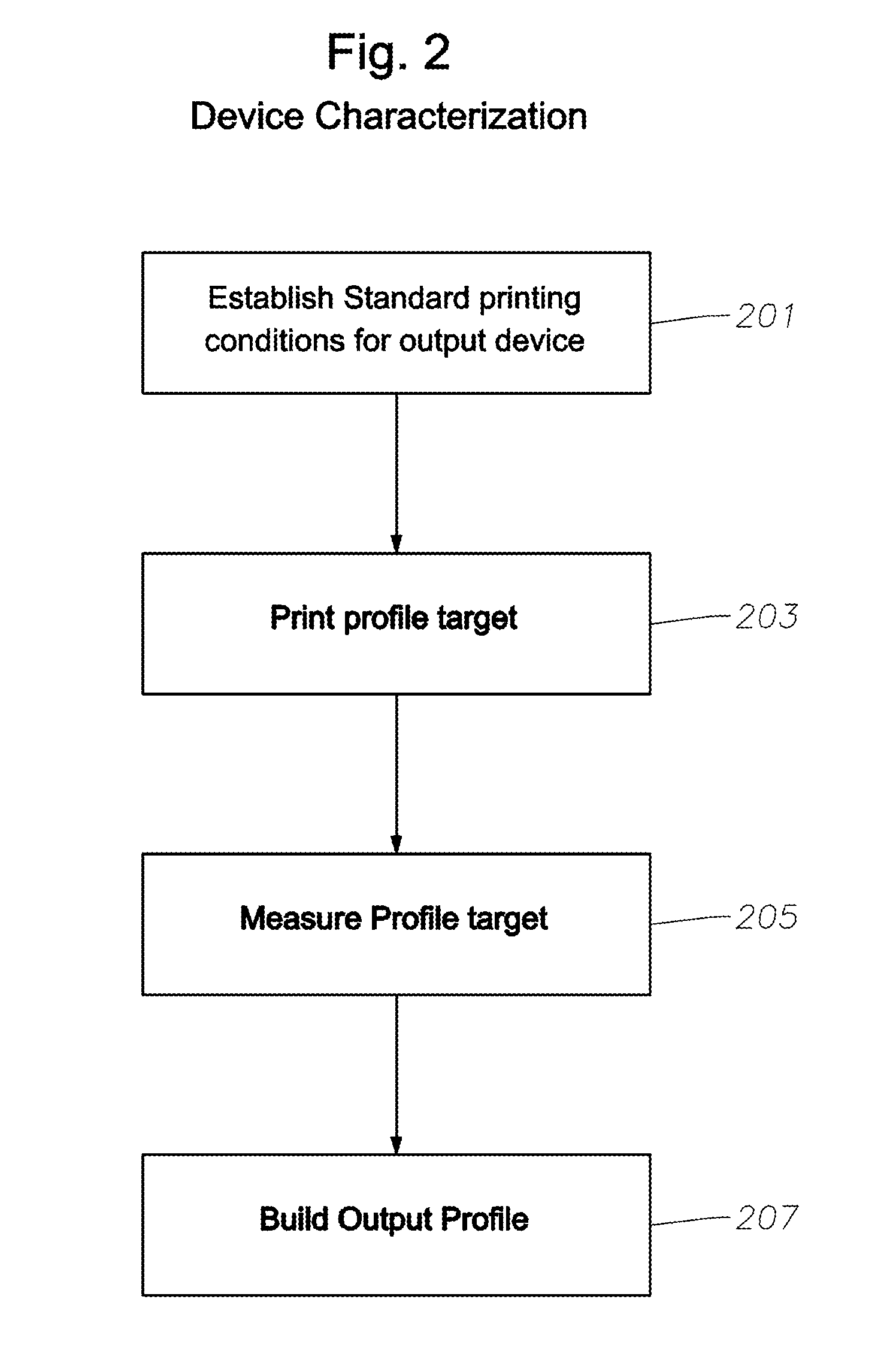

Methods And Apparatus For Assessing And Monitoring The Capability And Quality Of A color Reproduction System

InactiveUS20090087090A1Digitally marking record carriersDigital computer detailsColor imageICC profile

A color reproduction system comprises a color imaging output device (e.g., monitor, printer, etc.) and its device characterization (e.g., ICC profile, device link, etc.). A method for assessing the capability and accuracy of a color reproduction system is presented. This method may be used to assess the fit between a color reproduction system and its intended use (e.g., proofing, production, etc.). In addition, it may be used to monitor the color accuracy of a color reproduction system over time, thus informing users of the need to recalibrate and / or recharacterize the system.

Owner:JINDAL FILMS AMERICAS LLC

Remote color correction method

The invention relates to a remote color correction method and solves the technical problem that the method can be suitable for various medium and has the advantages of accurate color correction, simple and full-automatic operation, low requirements for operators and equipment configuration and low cost. The invention has the technical scheme that the method comprises the following steps: (1) respectively determining an ideal color correction target and a correction target; (2) by adopting the same electronic document D, by using a scheme A, namely, outputting the color correction target to obtain a picture A', and by using a scheme B, namely, outputting the color correction target to obtain a picture B'; (3) scanning the picture A' and the picture B' by using the same scanner to respectively obtain an electronic picture A'' and an electronic picture B'', and sending the electronic picture A'' and the electronic picture B'' to a color corrector through e-mail; and (4) generating a color description document by the color corrector according to the two electronic pictures, and sending the color description document to the user, wherein the color description document is a standard ICC profile document.

Owner:HANGZHOU CRON MACHINERY & ELECTRONICS CO LTD

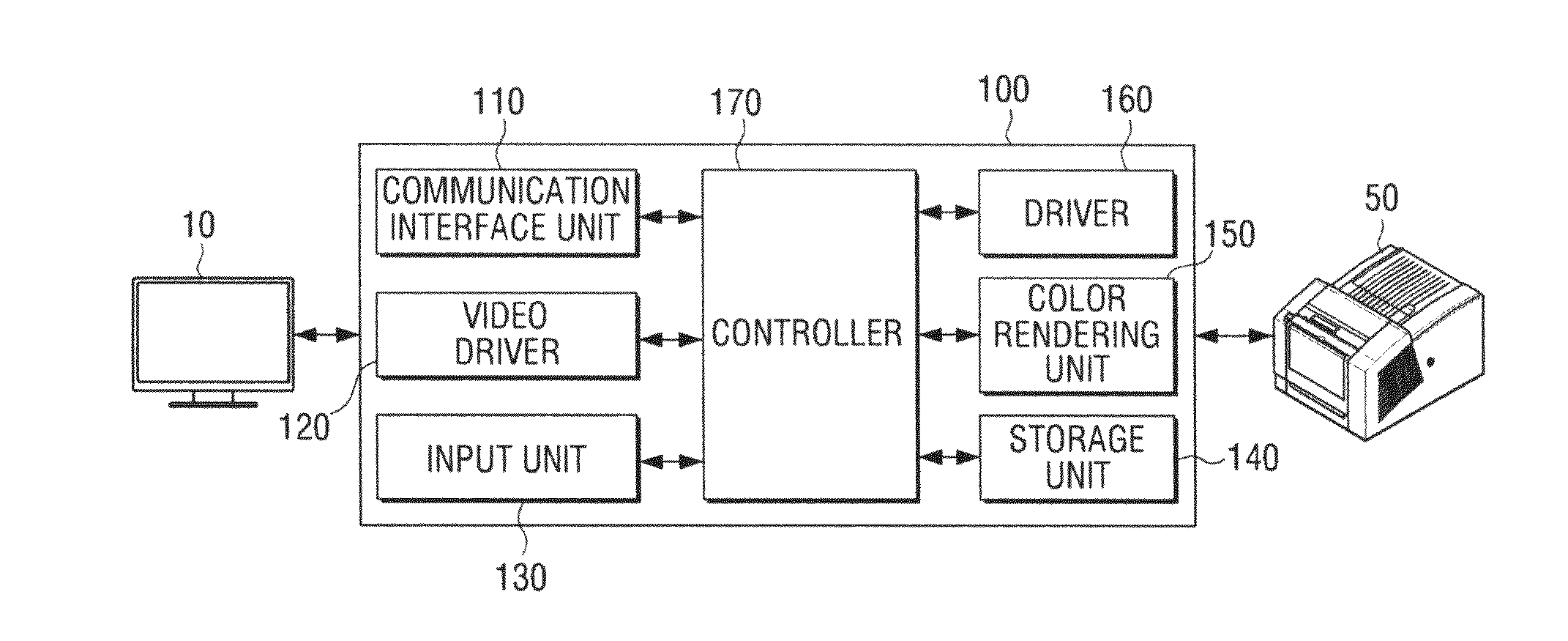

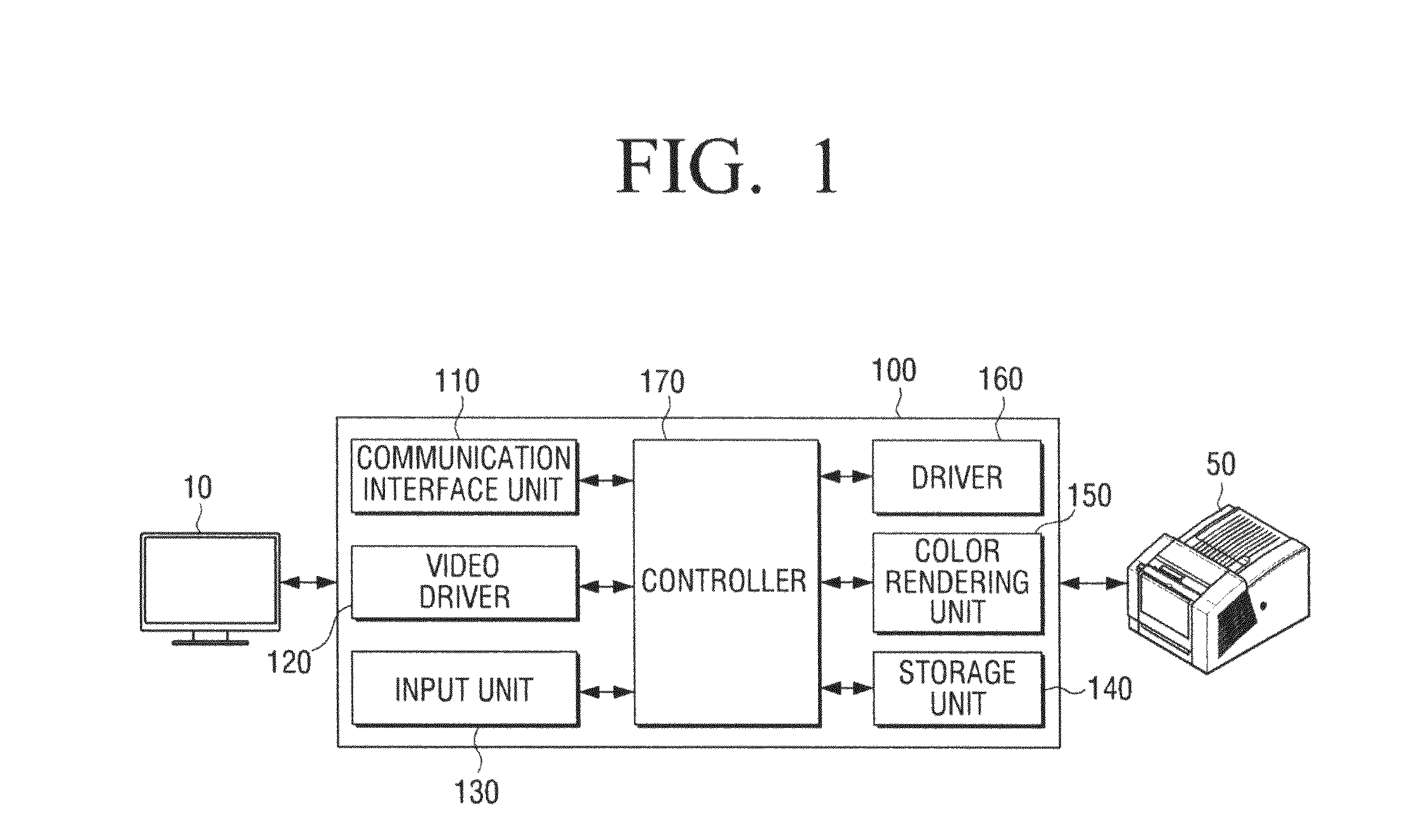

Method and device for color compensation

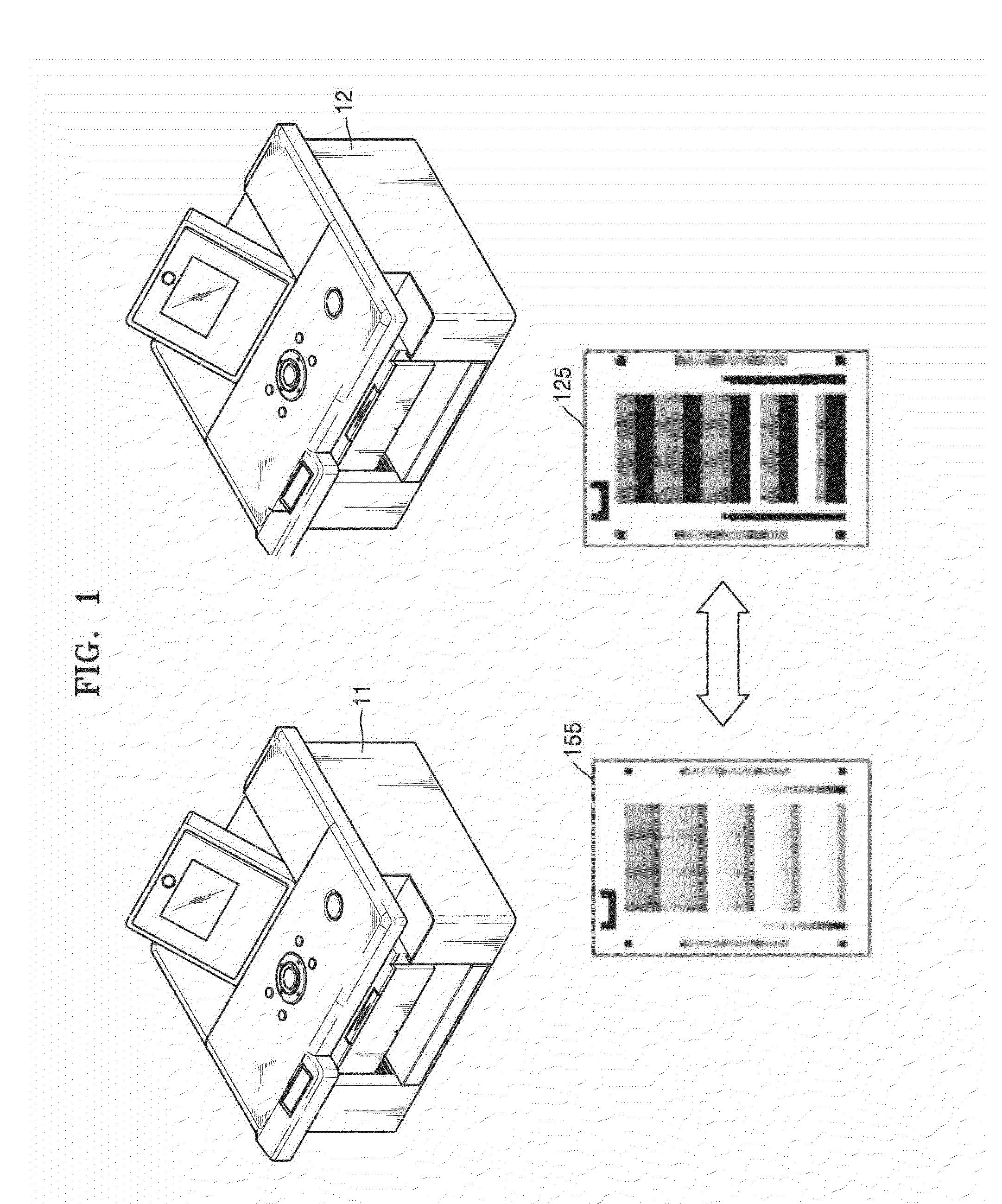

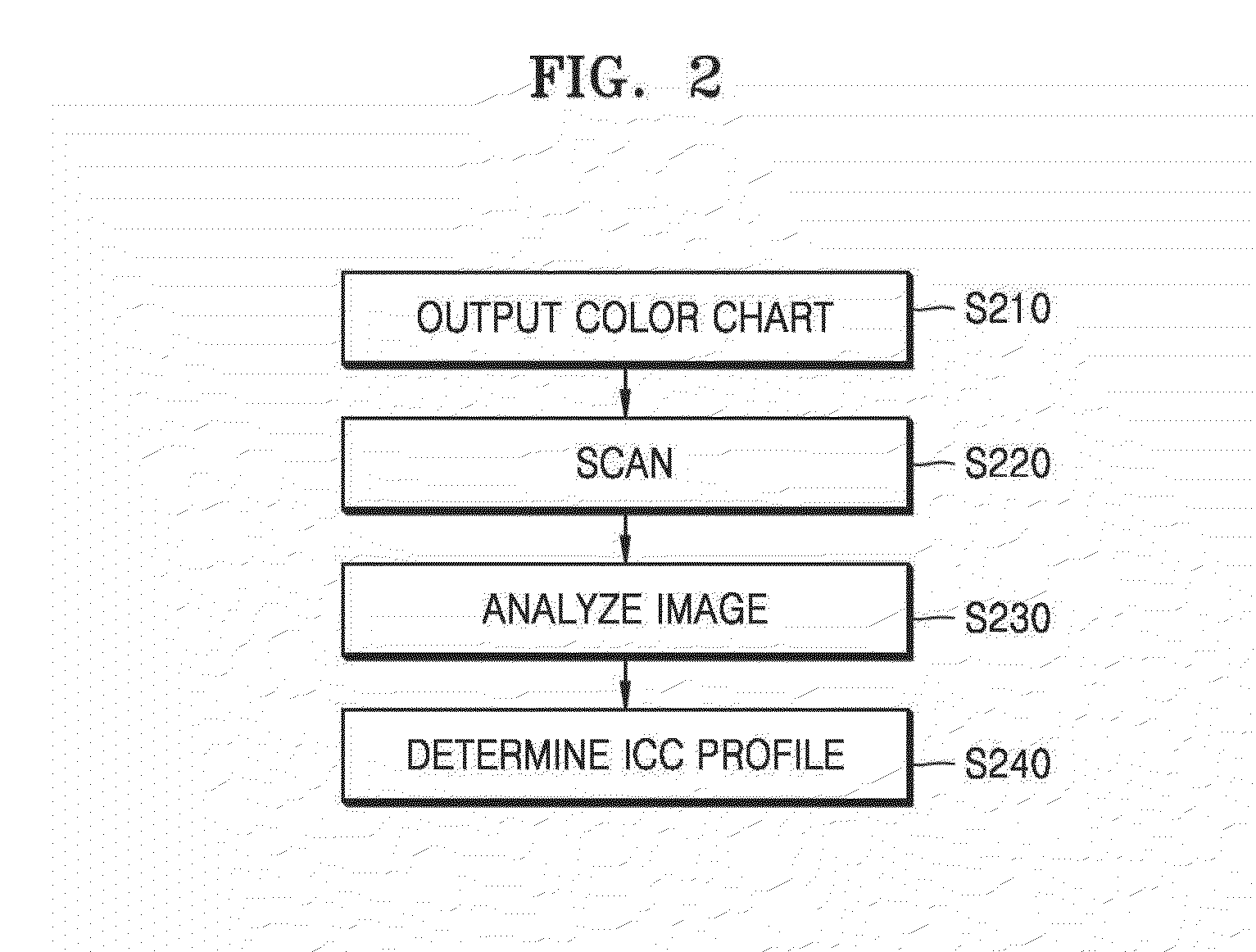

Provided is a color compensation method in an image forming apparatus. The color compensation method may include imaging a first color chart by a first image forming apparatus, scanning the imaged first color chart, comparing information regarding the scanned first color chart and information regarding a reference color chart to determine an international color consortium (ICC) profile of the first image forming apparatus, and performing color compensation on the first image forming apparatus based on the determined ICC profile.

Owner:HEWLETT PACKARD DEV CO LP

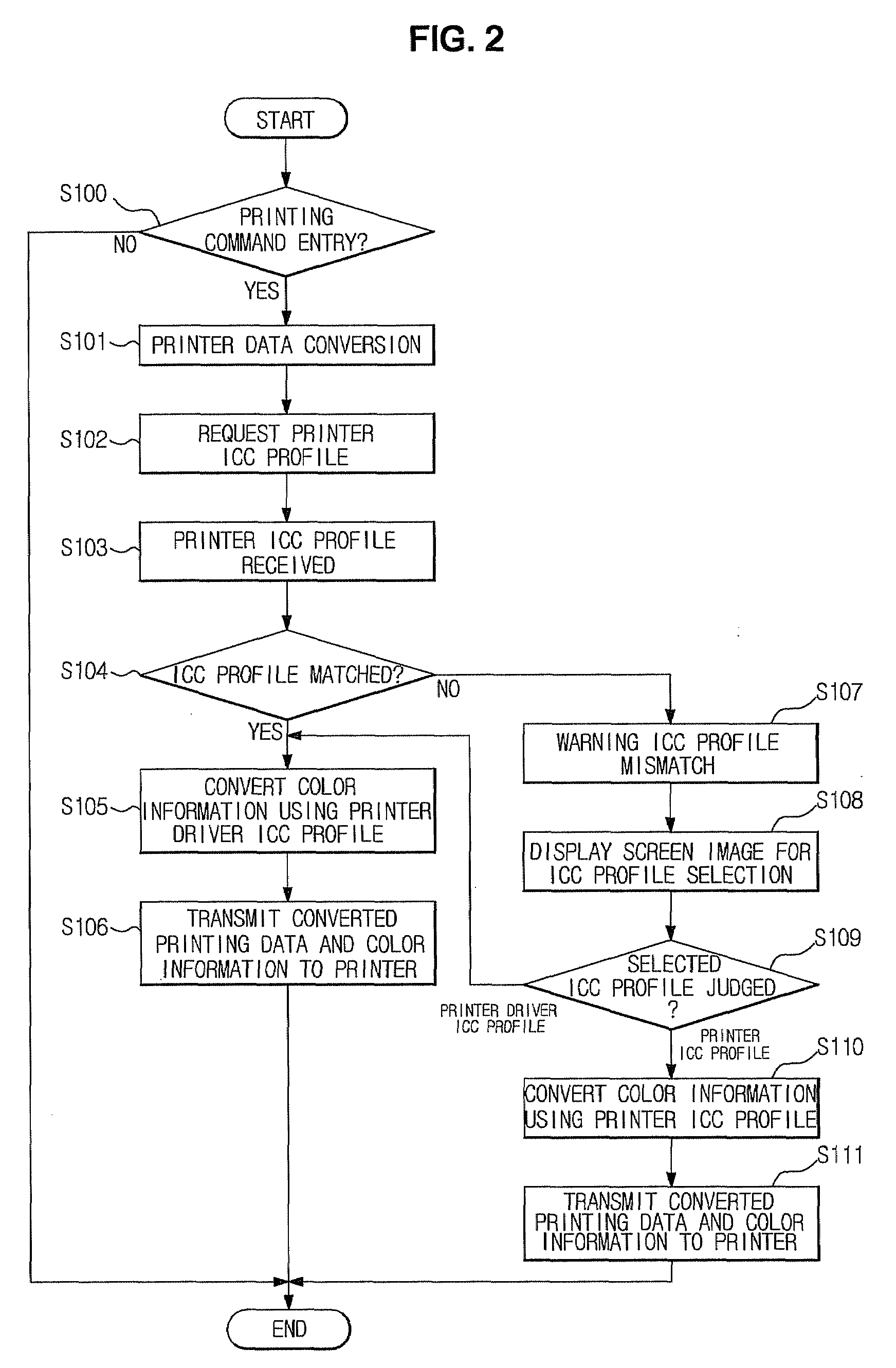

Host device having a printer driver and control method of the printer driver

InactiveUS20080212113A1Effective coloringColor matchingDigitally marking record carriersDigital computer detailsICC profileComputer printing

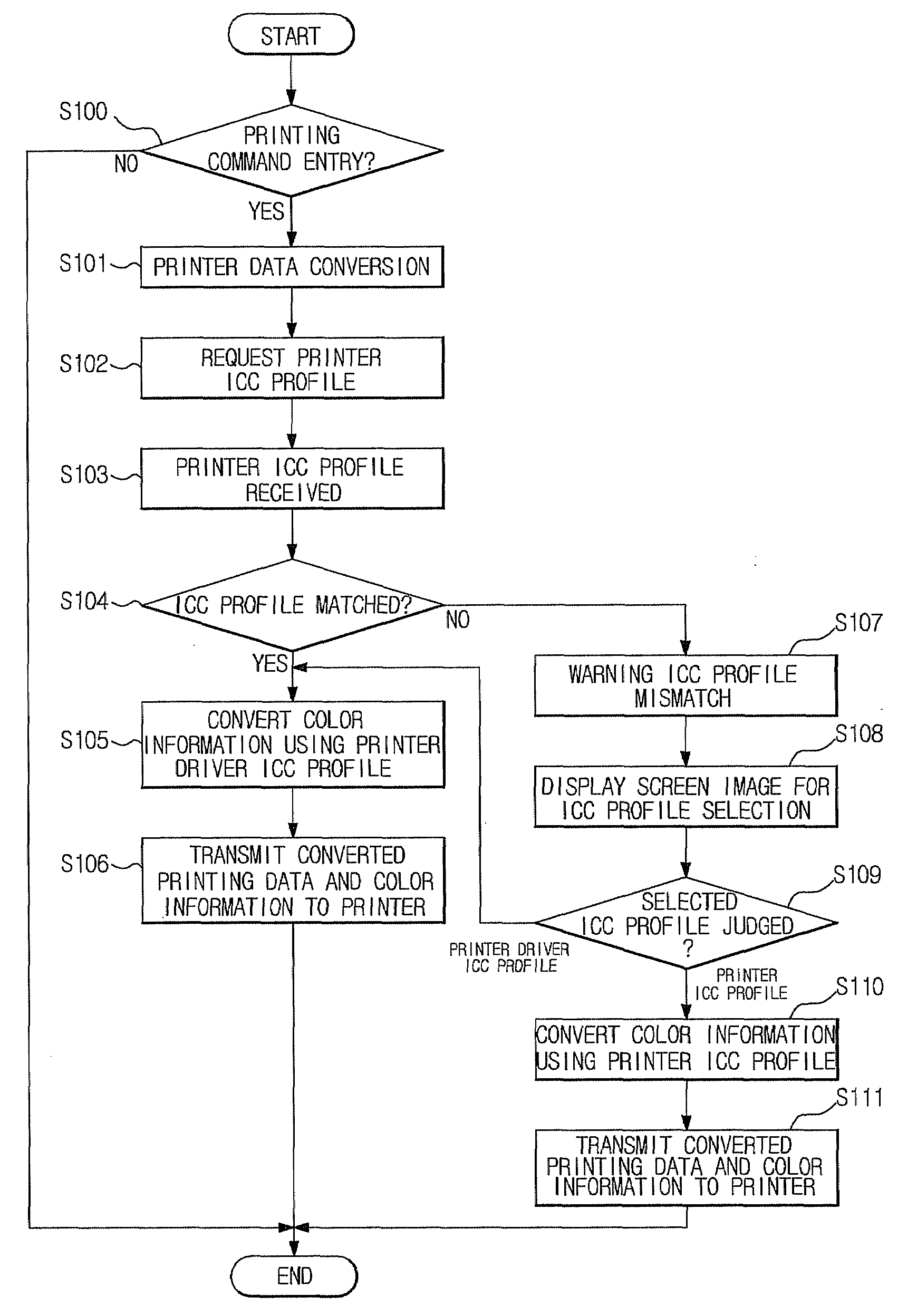

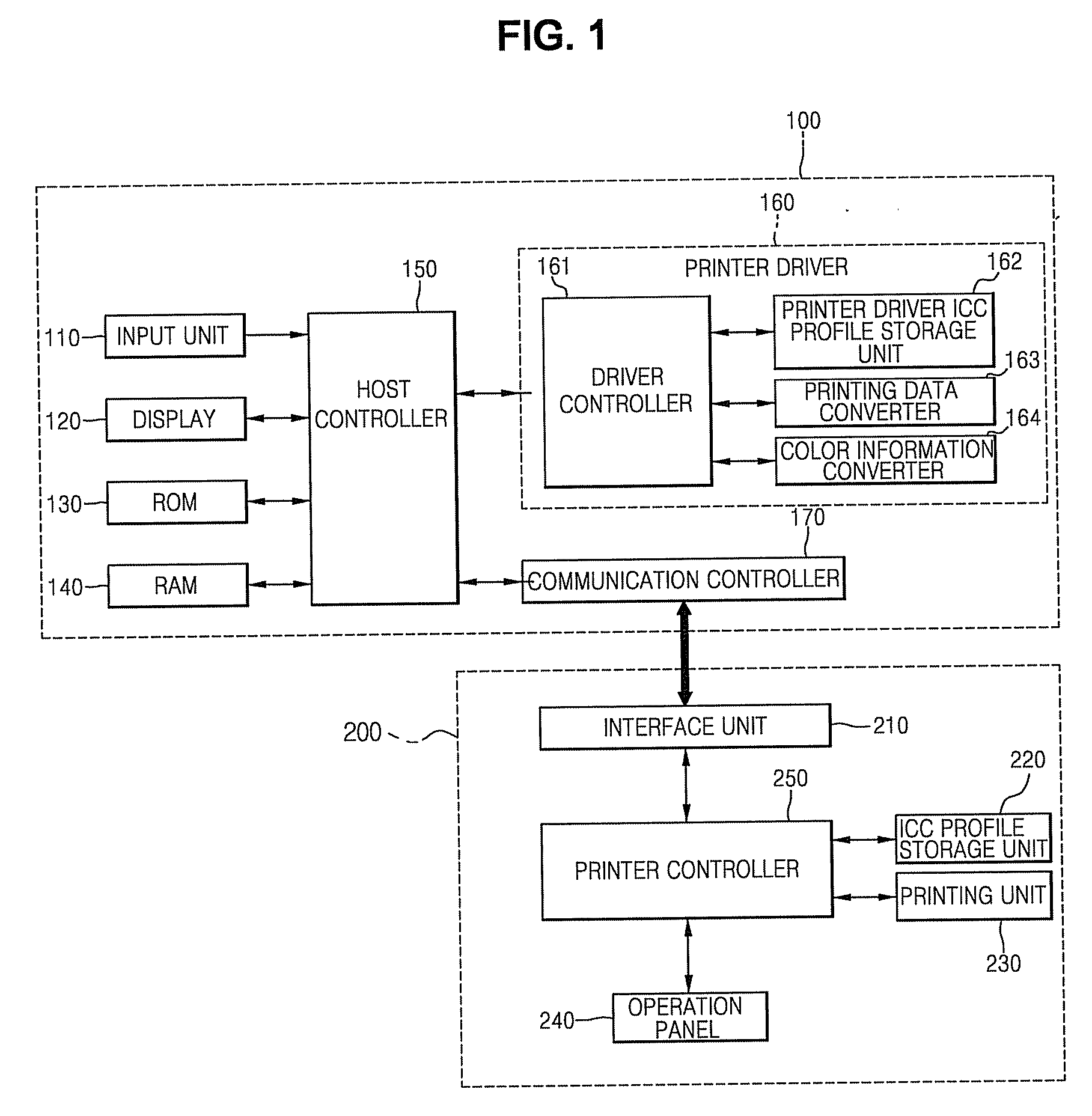

A printer driver and a method of controlling the same are disclosed. If the printer driver ICC profile does not correspond to the printer ICC profile, the printer driver converts color information of an image into predetermined information using the printer ICC profile instead of the printer driver ICC profile, such that the image forming apparatus can reproduce an optimum color as close to the original color of the image. The control method for the printer driver contained in a computer connected to an image forming apparatus includes determining whether an ICC profile of the image forming apparatus corresponds to an ICC profile established in the printer driver, and if the ICC profile of the image forming apparatus does not correspond to the ICC profile established in the printer driver, converting color information of the image into predetermined information using the ICC profile of the image forming apparatus.

Owner:S PRINTING SOLUTION CO LTD

Method to retrieve a gamut mapping strategy

ActiveUS20110134447A1Exact reproductionDigitally marking record carriersDigital computer detailsHard codingICC profile

What is disclosed is a novel system and method for retrieving a gamut mapping for a color device. A ray-based model is derived from a system estimation of either a seed profile or a seed device. The model is hard coded inside a run-time ICC profile creation algorithm. The runtime profile generation code can be optimized for a variety of gamut mapping scenarios. The generated profile is provided to an imaging system wherein out-of-gamut colors are mapped to the color gamut of the host device. The present method provides an accurate way to reproduce colors of images by retrieving the gamut mapping from profiles or from the color device that use destination profiles for rendering images.

Owner:XEROX CORP

Image data color conversion device

InactiveUS20050200869A1Easy to useImprove accuracyDigitally marking record carriersTexturing/coloringComputer hardwareICC profile

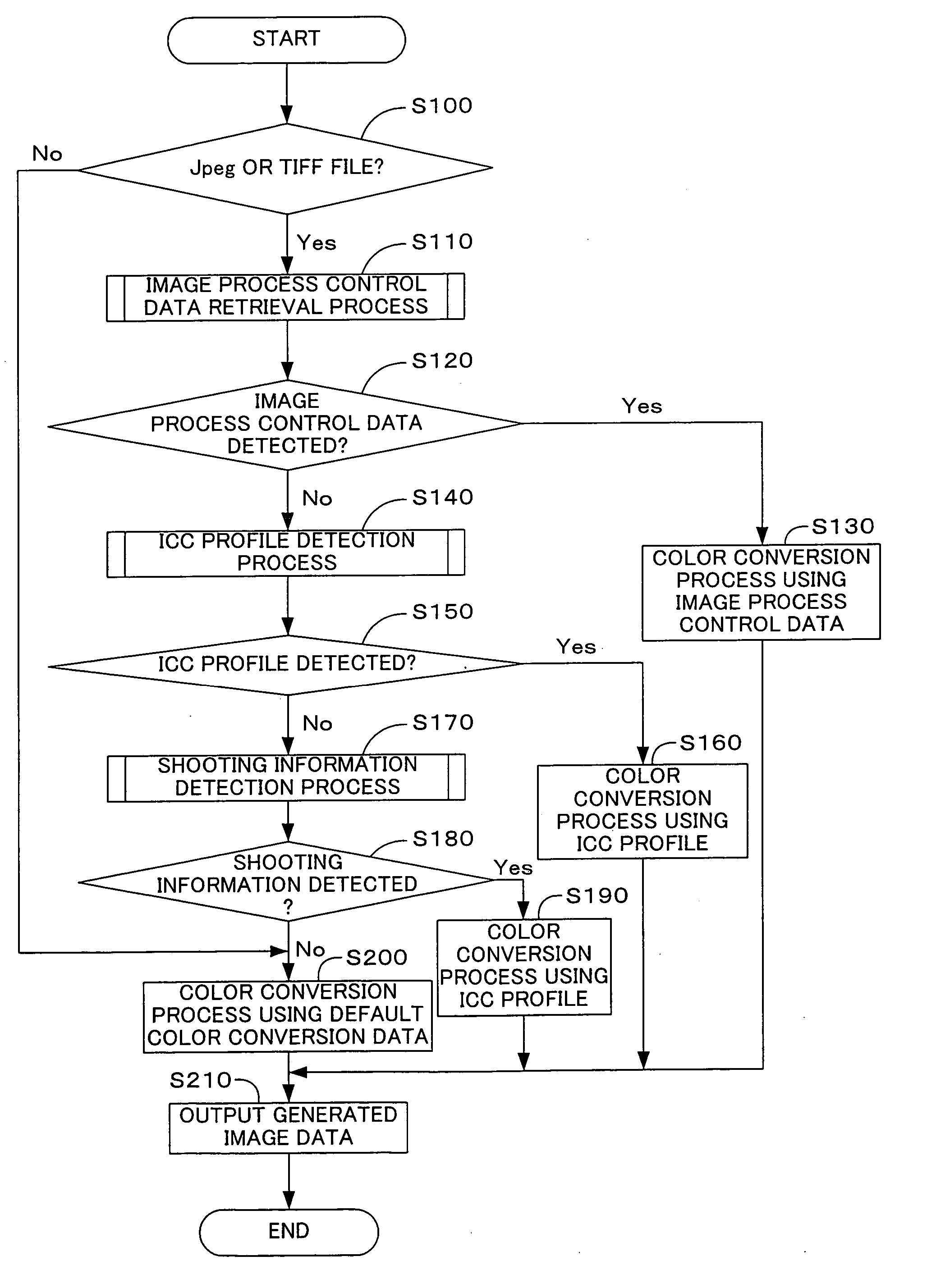

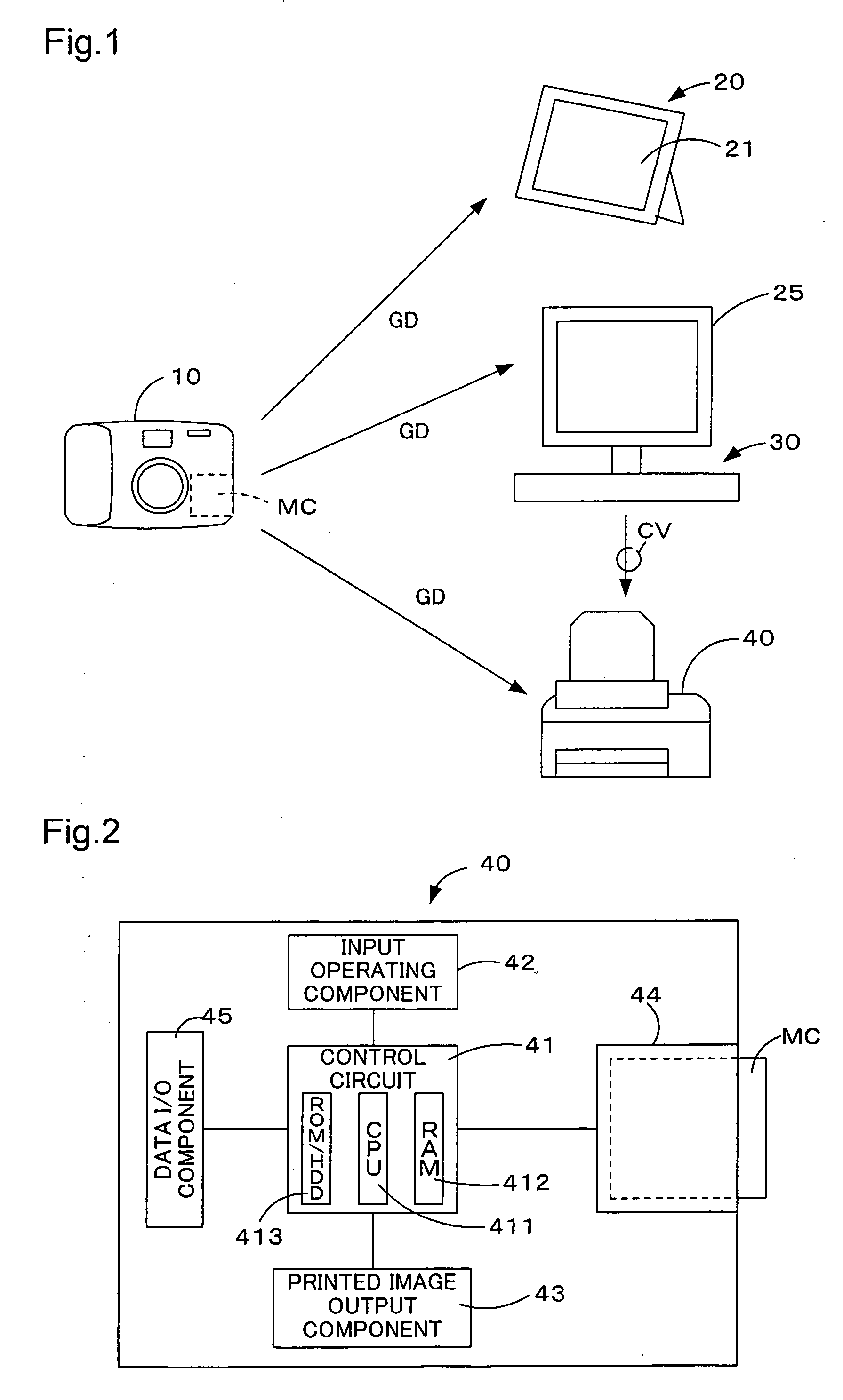

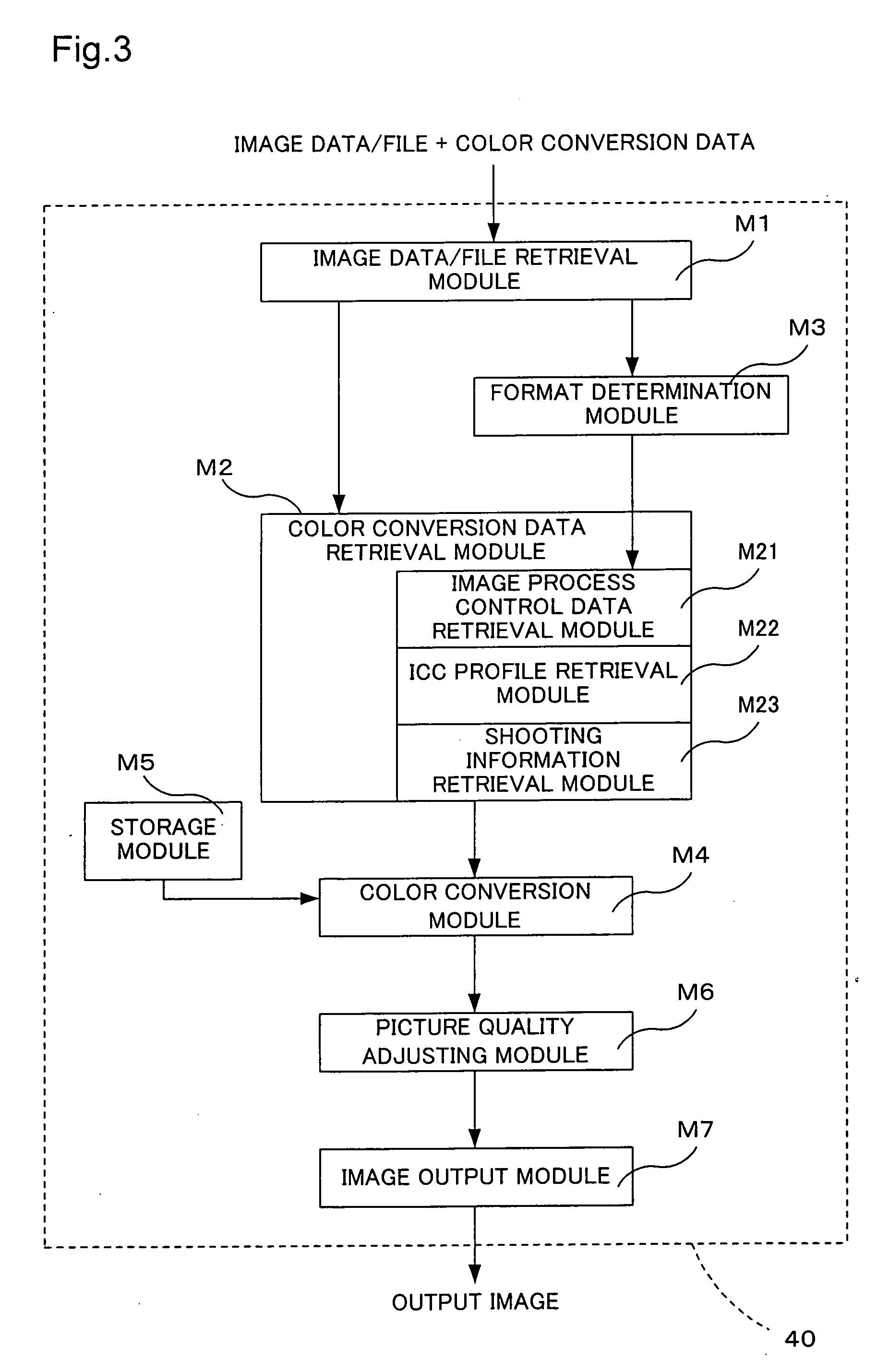

When the CPU 411 detects image process control data in the acqureed image file, a color conversion process is executed on the image data using the image process control data. When the CPU 411 cannot detect the image process control data, CPU 411 determines if the image file includes an ICC profile. When an ICC profile is detected, a color conversion process is executed on the image data using the ICC profile. When the CPU 411 cannot detect the image process control data or ICC profile, CPU 411 determines if the image file includes shooting information. When shooting information is detected, a color conversion process is executed on the image data using the shooting information.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com