Print system and color print method

a printing system and color printing technology, applied in the field of printing systems, can solve the problems of difficulty in achieving uncompromising demand for the ability to achieve satisfactory color during printing, and conventional systems that do not possess the capability to automatically adjust color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Before beginning description of embodiments, “color profiles” and “color matching,” repeated reference to which is made throughout such description, will be described.

[0032] Each of the various image processing devices (e.g., cameras, image scanners, display monitors, printers, etc.) has its own unique color space(s) in which operations are carried out and its own unique gamut(s), i.e., locus or loci of colors that can be created. For example, while display monitors all operate within RGB color space, gamut will vary from monitor to monitor. Likewise, gamuts of printers, which carry out operations in CMYK color space, will be different for different printers. Furthermore, even the same printer will exhibit different gamuts depending upon the type of ink and printing medium (printing paper) used therewith.

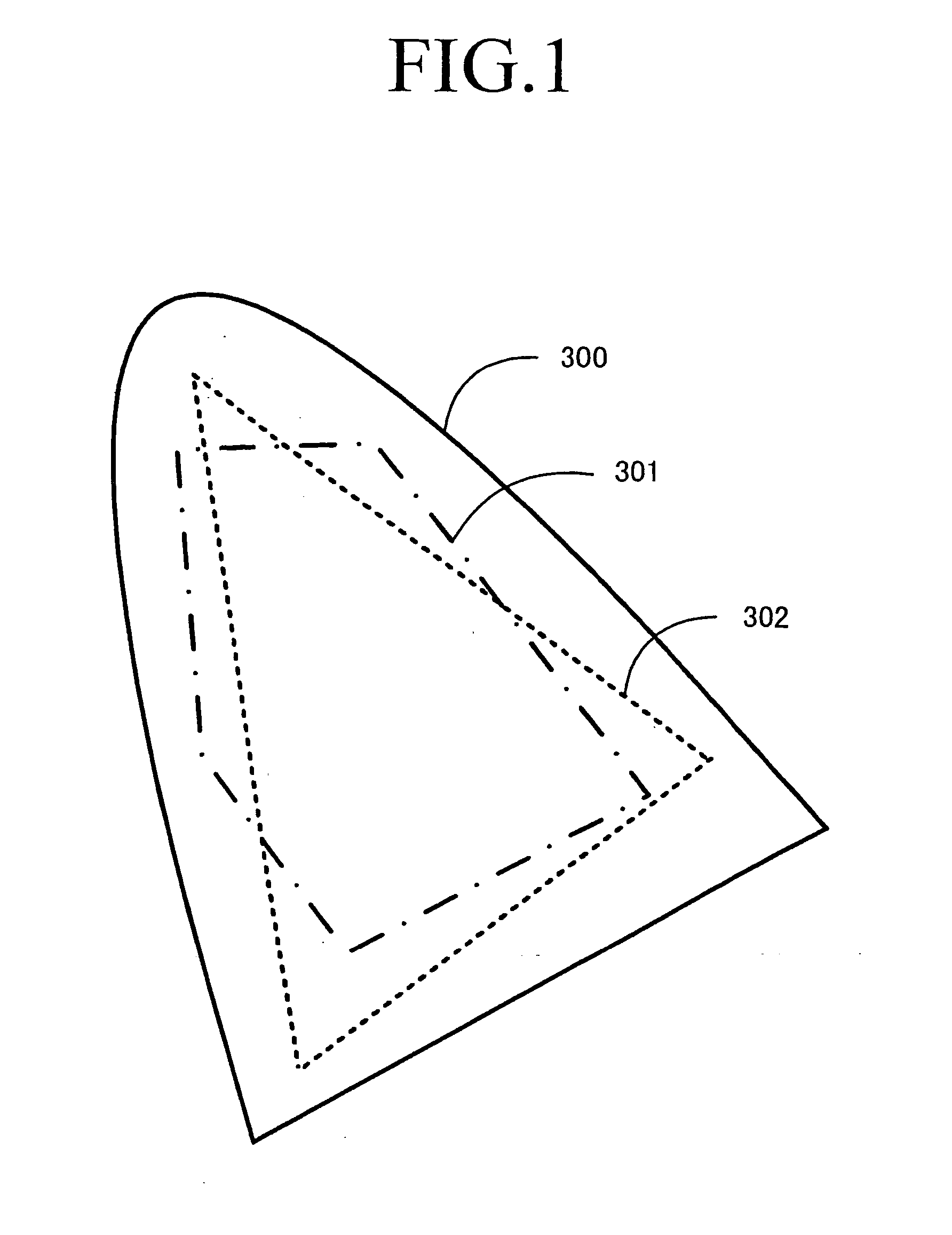

[0033]FIG. 1 is drawing showing a schematic example of gamuts of different devices. At FIG. 1, reference numeral 300 indicates gamut visibly perceivable by human beings, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com