A method for measuring the particle size distribution of solids in catalytic cracking oil slurry

A technology for catalytic cracking oil slurry and measurement method, which is applied in the field of determination of particle size distribution of solids in catalytic cracking oil slurry, and can solve the problem that the particle size distribution measurement method cannot comprehensively and accurately reflect the solid particle size of oil slurry diameter distribution and other issues to achieve low cost, ensure accuracy, and reduce agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

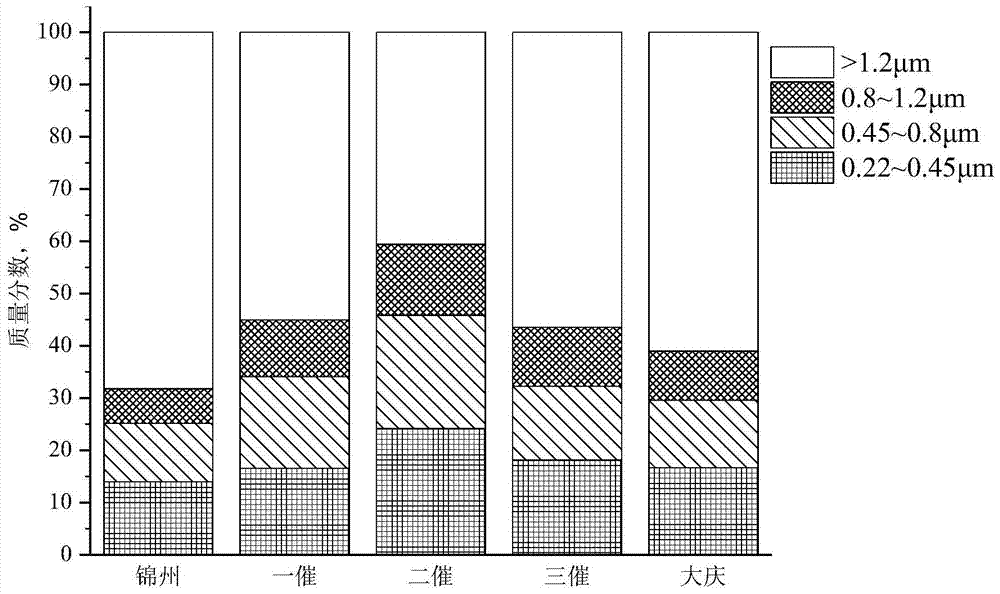

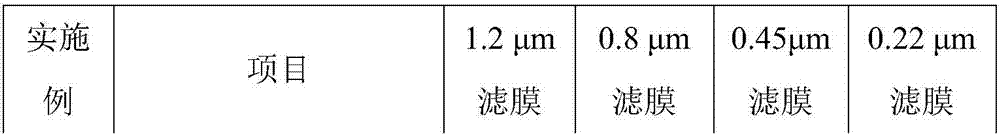

[0040] Jinzhou Petrochemical catalytic cracking oil slurry was used as the test object. The quality and dilution ratio of the oil slurry obtained are shown in Table 1. The filter membrane used is a polytetrafluoroethylene filter membrane. The particle size distribution measurement results are shown in Table 2 and figure 1 shown.

Embodiment 2

[0042] Jilin Petrochemical No. 1 catalyzed oil slurry was used as the test object. The selection of the oil slurry quality and dilution ratio is shown in Table 1. The filter membrane used is a polyvinylidene fluoride filter membrane. The particle size distribution measurement results are shown in Table 2 and figure 1 shown.

Embodiment 3

[0044] Jilin Petrochemical No. 2 oil slurry was used as the test object. The selection of the oil slurry quality and dilution ratio is shown in Table 1. The filter membrane used is a nylon filter membrane. The particle size distribution measurement results are shown in Table 2 and figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com