Anti-sticking spraying device for moulding sand box

A technology for molding sand and control devices, which is applied in the direction of injection devices, liquid injection devices, etc., can solve the problems of sandbox size changes, affecting equipment accuracy, iron jamming, etc., and achieve the effect of solving iron sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

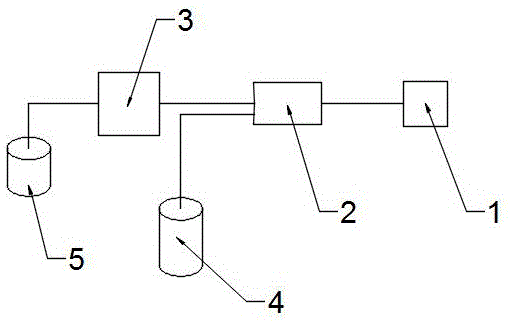

[0015] Such as figure 1 As shown, a molding sand box anti-sticking spraying device includes a spray gun 1, a spray gun mixing control device 2, a solenoid valve control device 3, a paint mixing bucket 4, and a compressed air bag 5, wherein the compressed air bag 5 and the solenoid valve control device 3 The air inlet end of the solenoid valve control device 3 is connected to the air inlet end of the spray gun mixing control device 2, the feed end of the spray gun mixing control device 2 is connected to the paint mixing tank 4, and the output of the spray gun mixing control device 2 The port is connected to the spray gun 1.

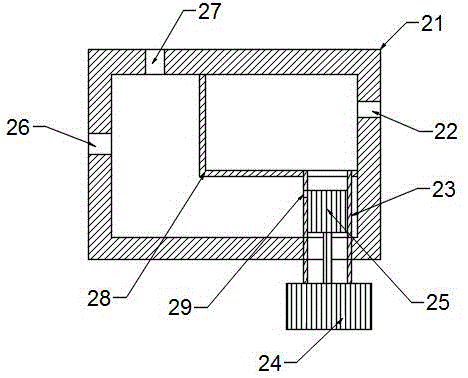

[0016] Among them, the core component - the spray gun mixing control device, such as figure 2 As shown, the spray gun mixing control device 2 includes an outer casing 21, and a partition 28 is arranged in the outer casing 21 to separate the inner space of the outer casing into an air storage chamber and a material chamber, and the outer casing 21 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com