Using method of round-head T-shaped pile manufacturing equipment

A round head, equipment technology, used in drilling equipment, drill bits, sheet pile walls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

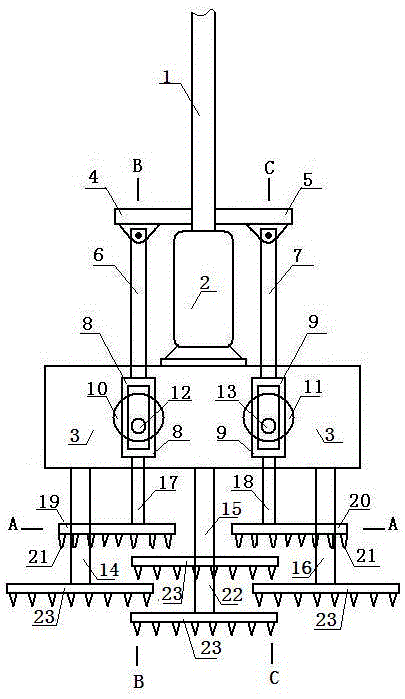

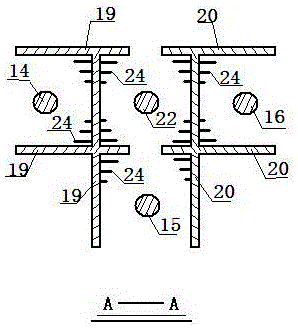

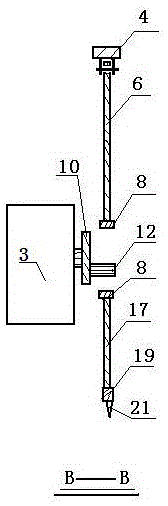

[0016] Accompanying drawing is a kind of concrete embodiment of the present invention, and this embodiment drill rod 1 lower end is fixed motor 2 upper end, and motor lower end is provided with gearbox 3, and gearbox lower end is provided with rotating shaft one 14, rotating shaft two 15, rotating shaft three 16, rotating shaft Four 22, each rotating shaft lower end is respectively provided with a drill bit 23; Gearbox front left part is provided with a round wheel-10, and the upper eccentric fixed shaft body-12 of round wheel-, shaft body-is arranged in the rectangle frame-8, The upper end of rectangular frame one is fixed on the lower end of long vertical arm one 6, and the upper end of long vertical arm one hinges the left end of extension rod one 4, and the right end of extension rod one is fixed on drill pipe, and the lower end of rectangular frame one is fixed on The upper end of the short vertical arm one 17, the lower end of the short vertical arm one is fixed with the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap