A method for adjusting a six-roll cold rolling mill and the six-roll cold rolling mill

An adjustment method and cold rolling mill technology, which is applied to the adjustment of six-high cold rolling mills, in the field of six-high cold rolling mills, can solve the problems of insufficient crown control ability and narrow rolling width range of six-high UCM cold rolling mills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

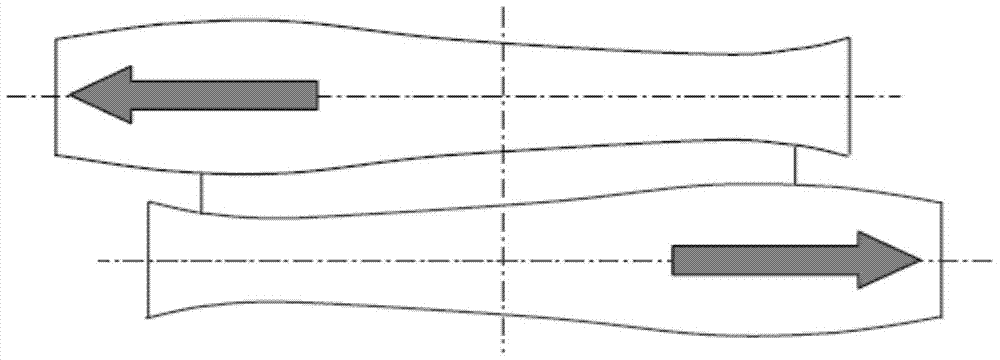

[0033] The embodiment of the present invention provides an adjustment method of a six-high cold rolling mill and a six-high cold rolling mill to solve the problem of the crown control ability of the six-high CVC cold rolling mill in the prior art when rolling a narrow strip. Insufficient technical problems, as well as the narrow technical problem of the rolling width range of the six-high UCM cold rolling mill.

[0034] The technical solution in the embodiment of the present invention is to solve the above-mentioned technical problems, and the general idea is as follows:

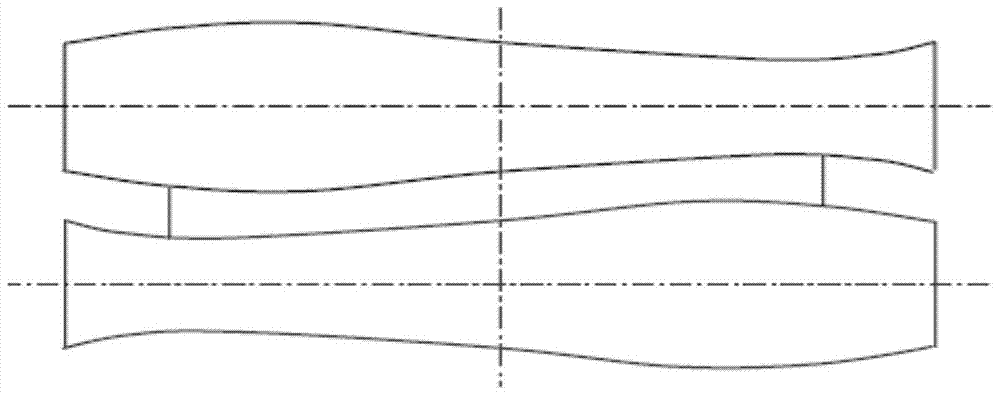

[0035] An embodiment of the present invention provides a method for adjusting a six-high cold rolling mill, the six-high cold rolling mill includes two backup rolls, two intermediate rolls and two work rolls, wherein the two intermediate rolls are arranged on the two backup rolls Between, two working rolls are set between two intermediate rolls;

[0036] Among them, the adjustment formula of the roll shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com