A gob-side roadway mining method for ultra-long advancing distance working face

A mining method and a technology of advancing distance, which are used in surface mining, earthwork drilling, underground mining, etc., can solve the problems of large coal pillar size and skip mining, and achieve the effect of ensuring auxiliary transportation and simple maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

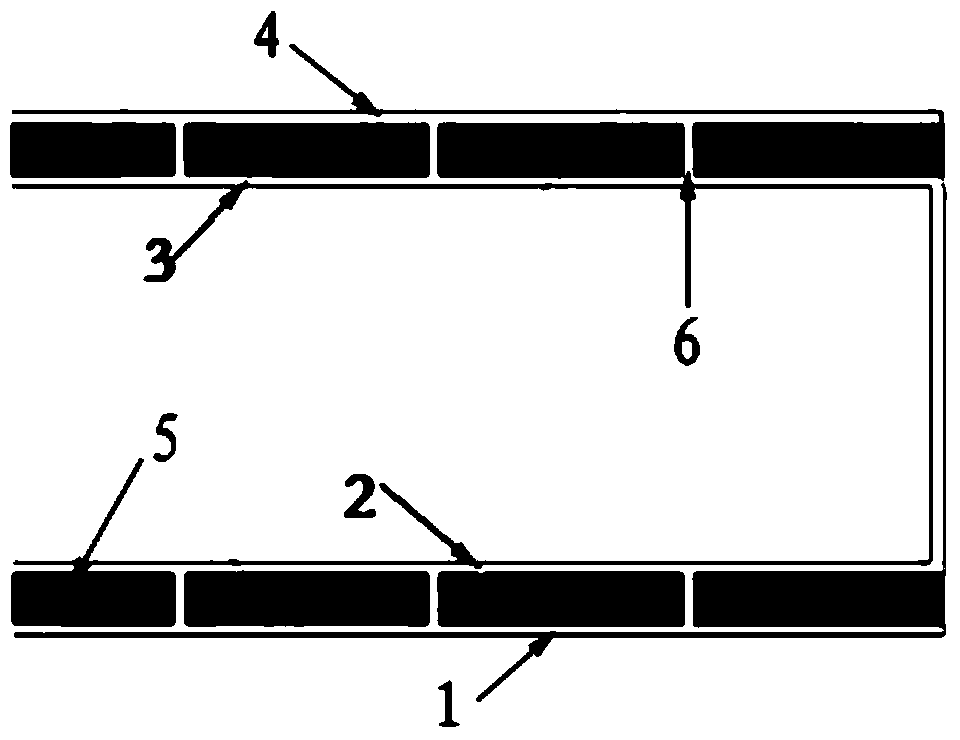

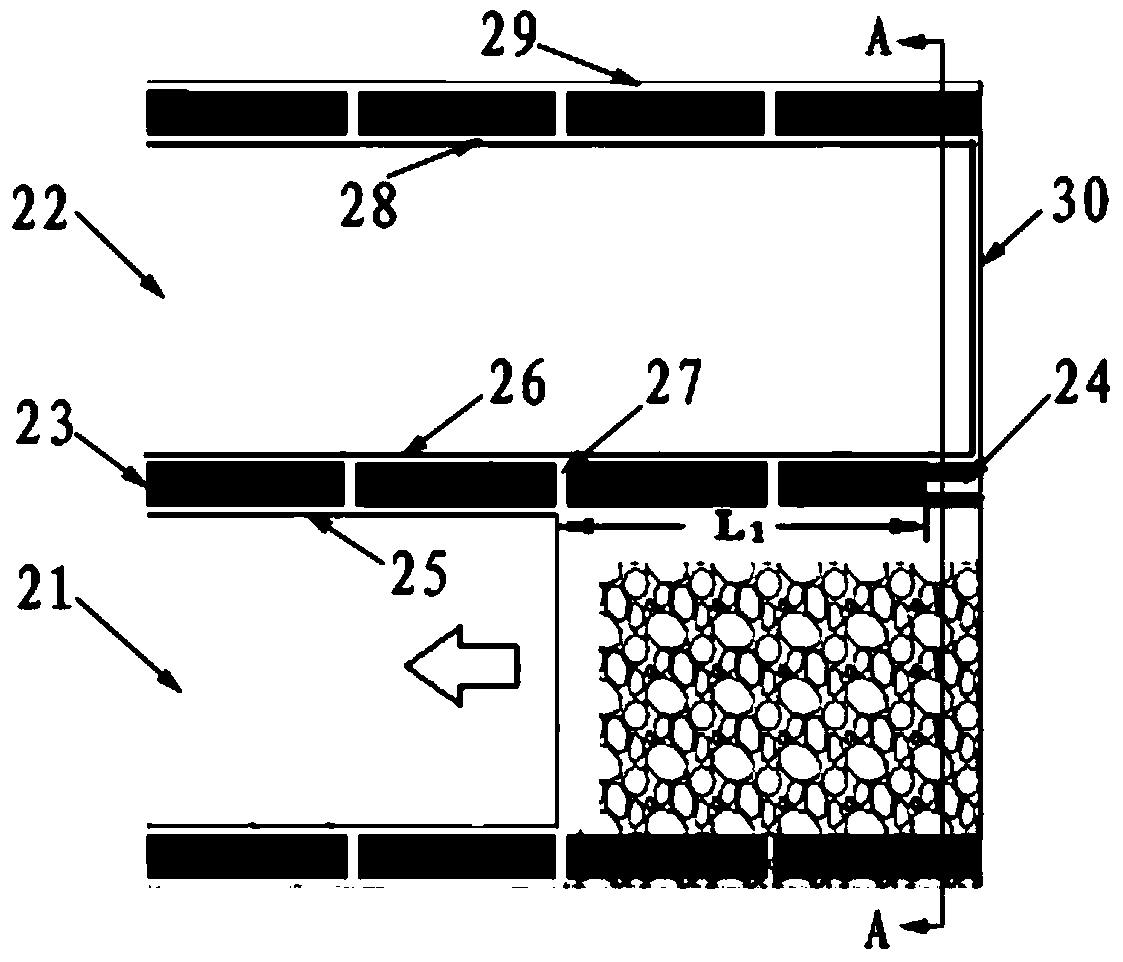

[0057] The 3-1 coal seam is mined in the 31 mining area of the Chahasu Coal Mine. The thickness of the coal seam is 2.05-7.15m, with an average of 5.25m. The average dip angle of the coal seam is 1°. The researched mining face is located in the middle of mining area 31, with a dipping length of 300m and a advancing length of 5,000m. It adopts a double roadway layout, and the coal pillars between the two roadways have a clear width of 18.42m. A connecting roadway is opened every 60-70m. The remaining coal pillars and roadways are affected by two mining operations.

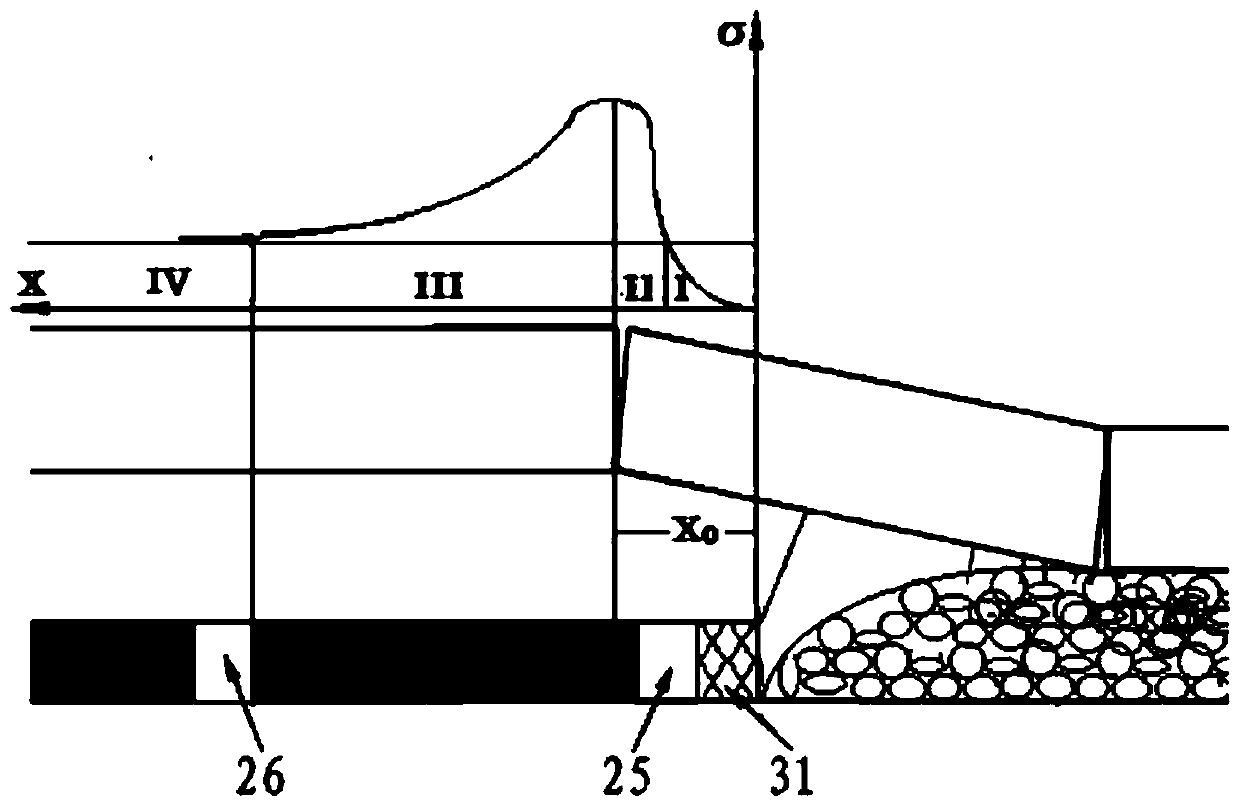

[0058] The stress distribution in the goaf side of the mining face (that is, the direction of the continuous working face) was measured. In the case of one mining operation (mining of the mining face), the stress peak point is 25m away from the goaf, and the maximum peak value is 22.94 MPa, for the specific stress distribution, see Figure 5(Wherein, the abscissa is the distance between one side of the continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com