pneumatic tire

A pneumatic tire, tire circumferential technology, applied to tire parts, tire tread/tread pattern, transportation and packaging, etc. The effect of braking performance on ice and improving driving stability on snow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

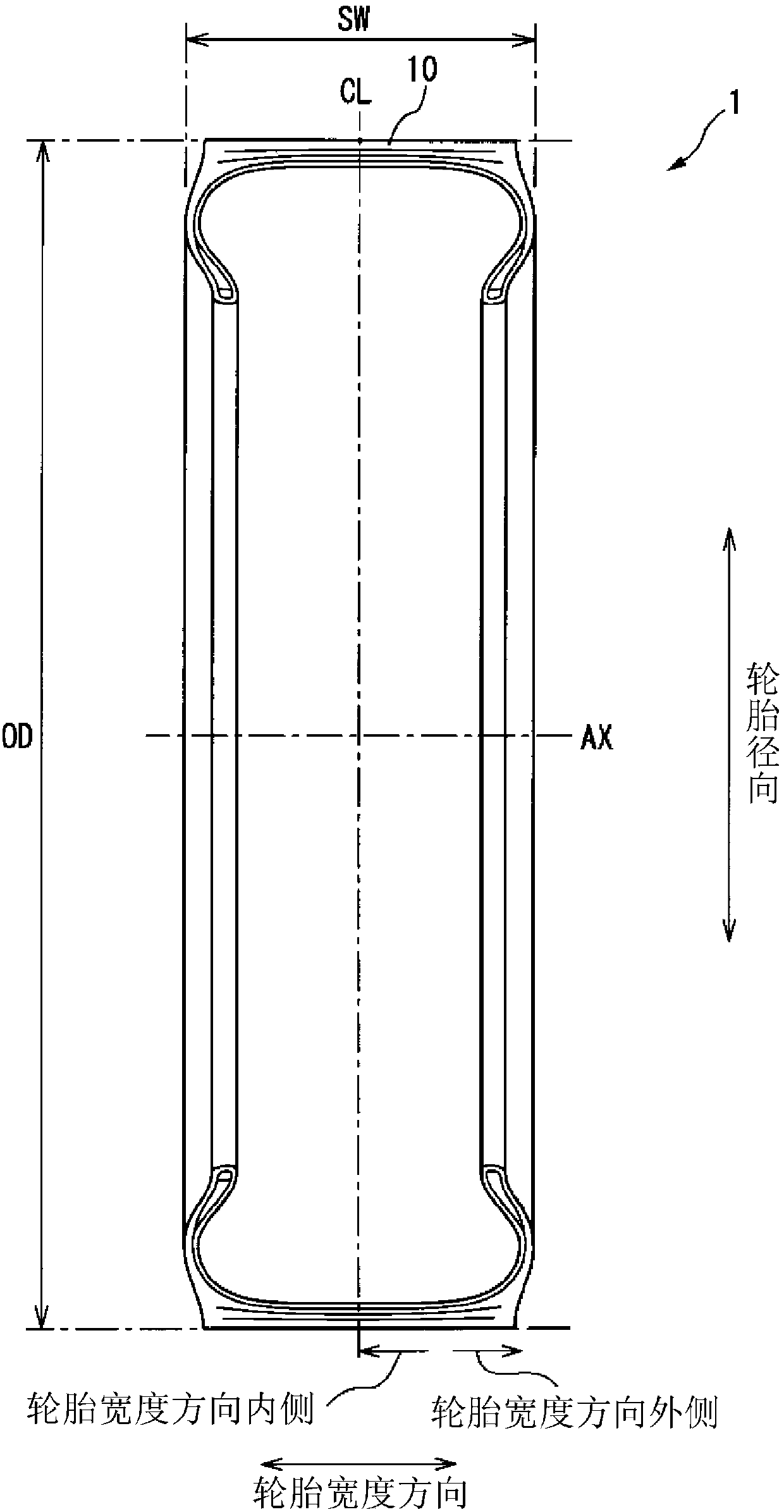

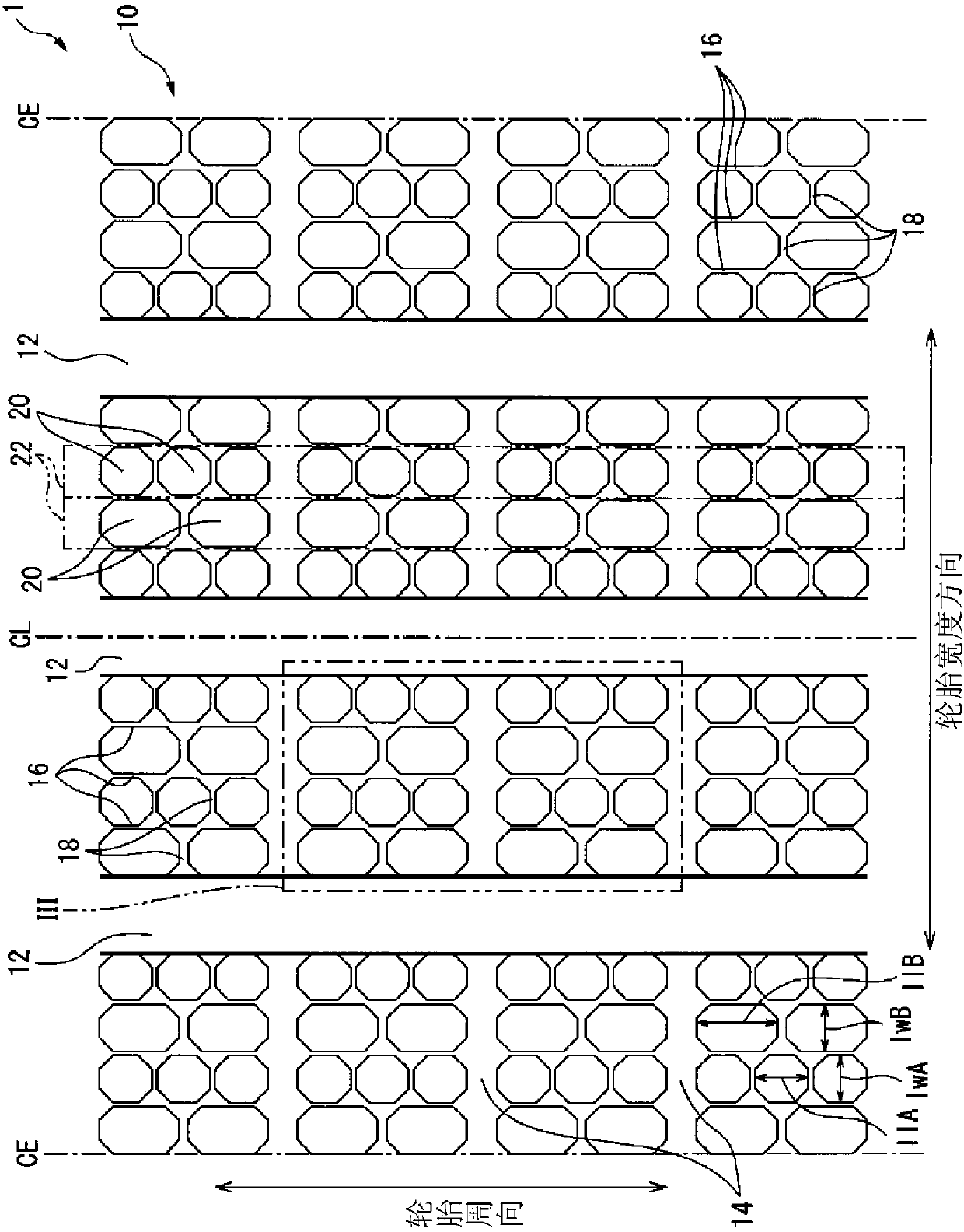

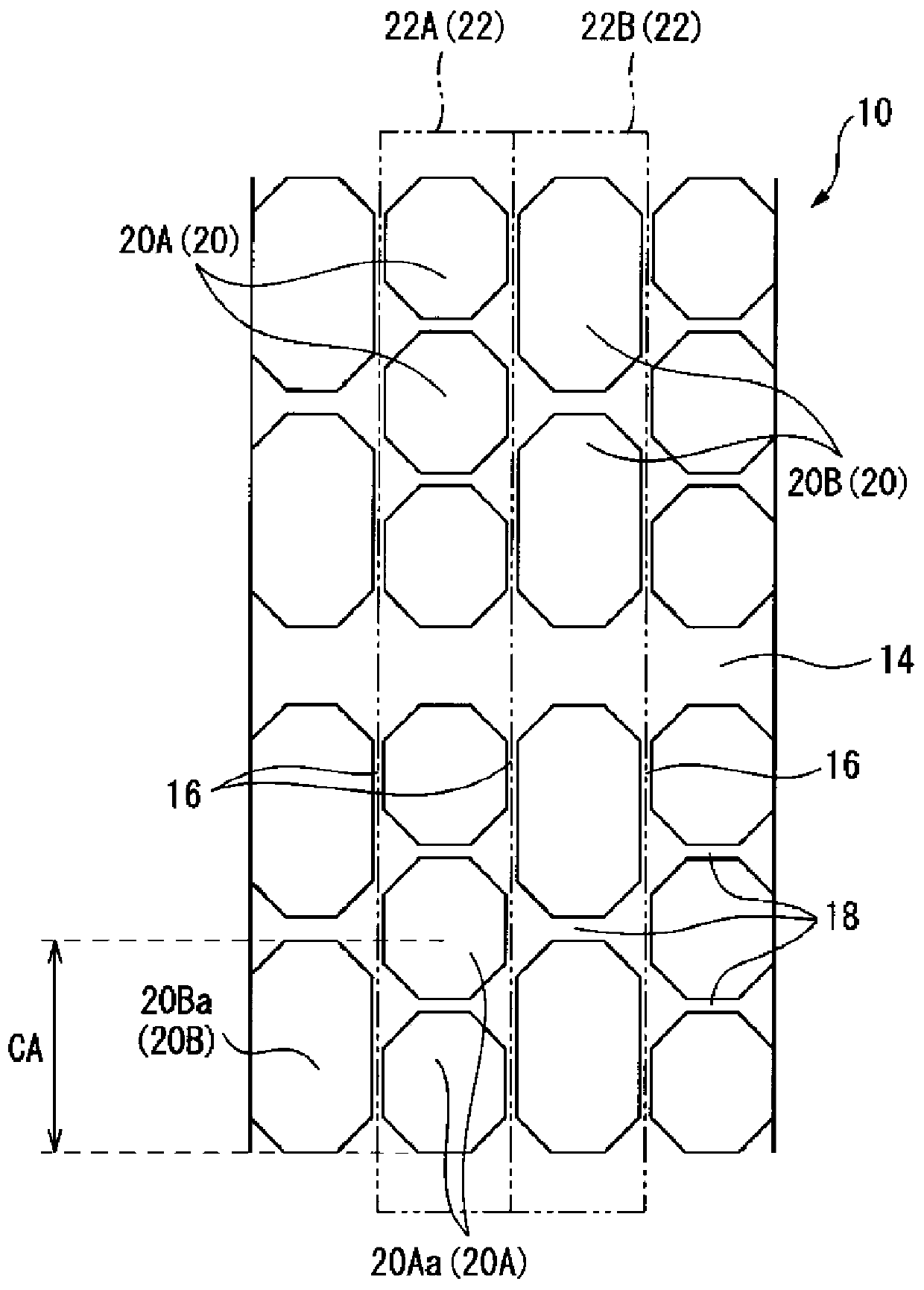

[0026] Hereinafter, a pneumatic tire 1 according to a first embodiment of the present invention will be described with reference to the drawings. figure 1 It is a meridian sectional view of the pneumatic tire 1 according to the first embodiment of the present invention. In addition, the meridian cross-sectional shape of the pneumatic tire 1 according to the first embodiment is the same as that of a conventional pneumatic tire. Here, the meridian cross-sectional shape of the pneumatic tire refers to the cross-sectional shape of the pneumatic tire appearing on a plane perpendicular to the tire equatorial plane CL.

[0027] In the following description, the tire radial direction refers to a direction perpendicular to the rotation axis AX of the pneumatic tire 1 . The tire circumferential direction refers to the direction that rotates around the above-mentioned rotation axis AX (see figure 2 ). In addition, the tire width direction refers to a direction parallel to the above-m...

no. 2 approach

[0050] Below, refer to Figure 4 , the pneumatic tire 1 according to the second embodiment of the present invention will be described. Figure 4 It is a schematic development plan view showing a part of the tread portion 10 of the pneumatic tire 1 according to the second embodiment of the present invention. In addition, regarding the second embodiment, only the points of difference from the first embodiment will be described.

[0051] Such as Figure 4 As shown, in the pneumatic tire 1 according to the second embodiment, like the pneumatic tire 1 according to the first embodiment, lug grooves 14 are provided to communicate the circumferential main grooves 12 with each other or connect the circumferential main grooves 12 to the ground. Terminal CE is connected. Here, in the pneumatic tire 1 according to the first embodiment, the distance between lug grooves 14 adjacent in the tire circumferential direction is constant. On the other hand, in the pneumatic tire 1 according to...

no. 3 approach

[0057] Below, refer to Figure 5 , the pneumatic tire 1 according to the third embodiment of the present invention will be described. Figure 5 It is a schematic development plan view showing a part of the tread portion 10 of the pneumatic tire 1 according to the third embodiment of the present invention. In addition, regarding the third embodiment, only the points of difference from the first embodiment will be described. The pneumatic tire 1 according to the third embodiment is different from the pneumatic tire 1 according to the first embodiment in that the shape of the small blocks 20 is an arrow-feather shape directed toward the tire circumferential direction.

[0058] In the pneumatic tire 1 according to the third embodiment, as Figure 5 As shown, the small block 20 has a convex portion 20P on one side in the tire circumferential direction that is convex toward the small block adjacent in the tire circumferential direction, and has a convex portion 20P on the other si...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap