Component Recognition System for Component Mounter

A component identification and mounting machine technology, applied to electrical components, electrical components, etc., can solve problems such as the inability to obtain height data and the inability to check the lead bending of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, an example which actualized the form for carrying out this invention is demonstrated.

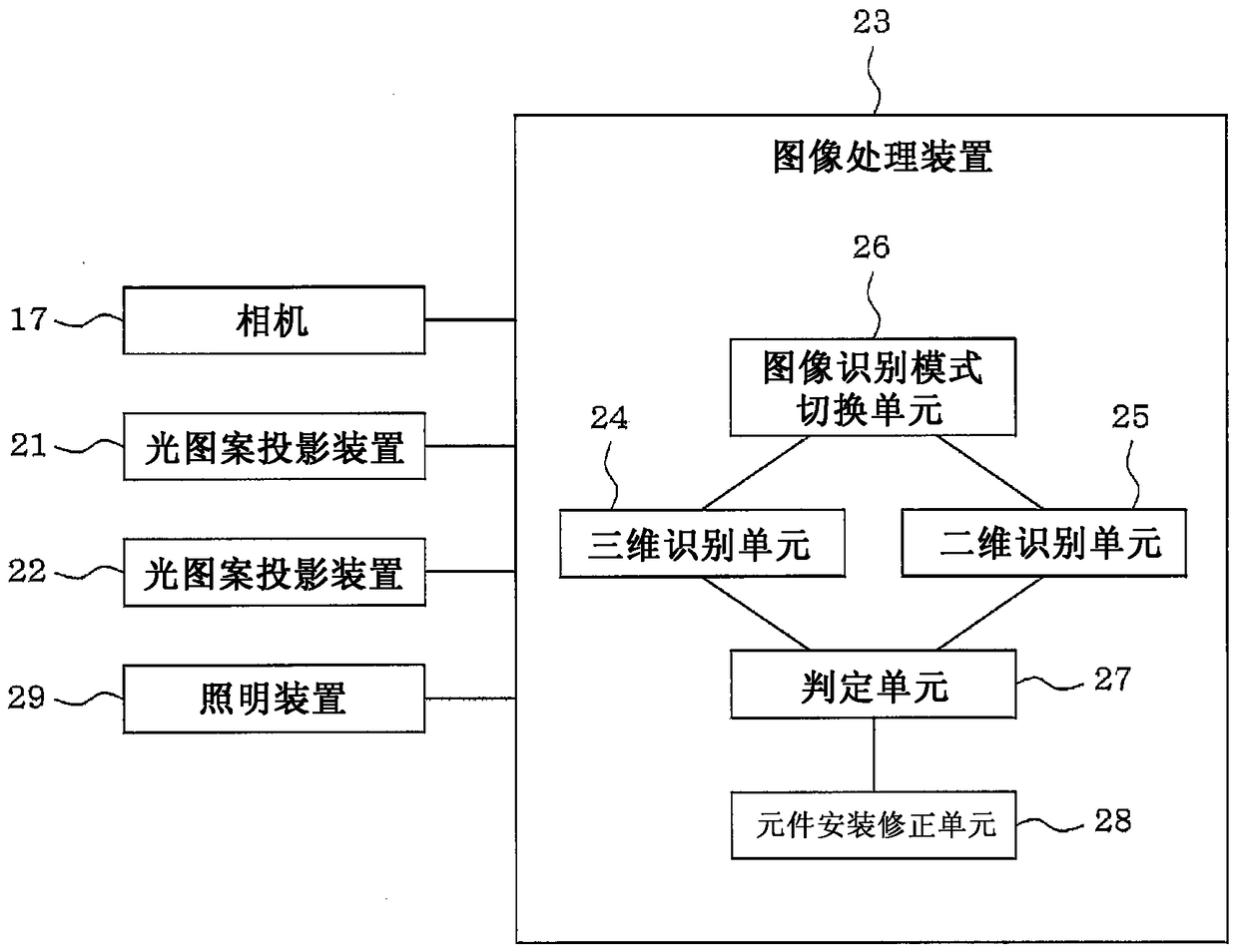

[0022] First, use Figure 1 to Figure 3 The configuration of the component recognition system of the component mounting machine of this embodiment will be described.

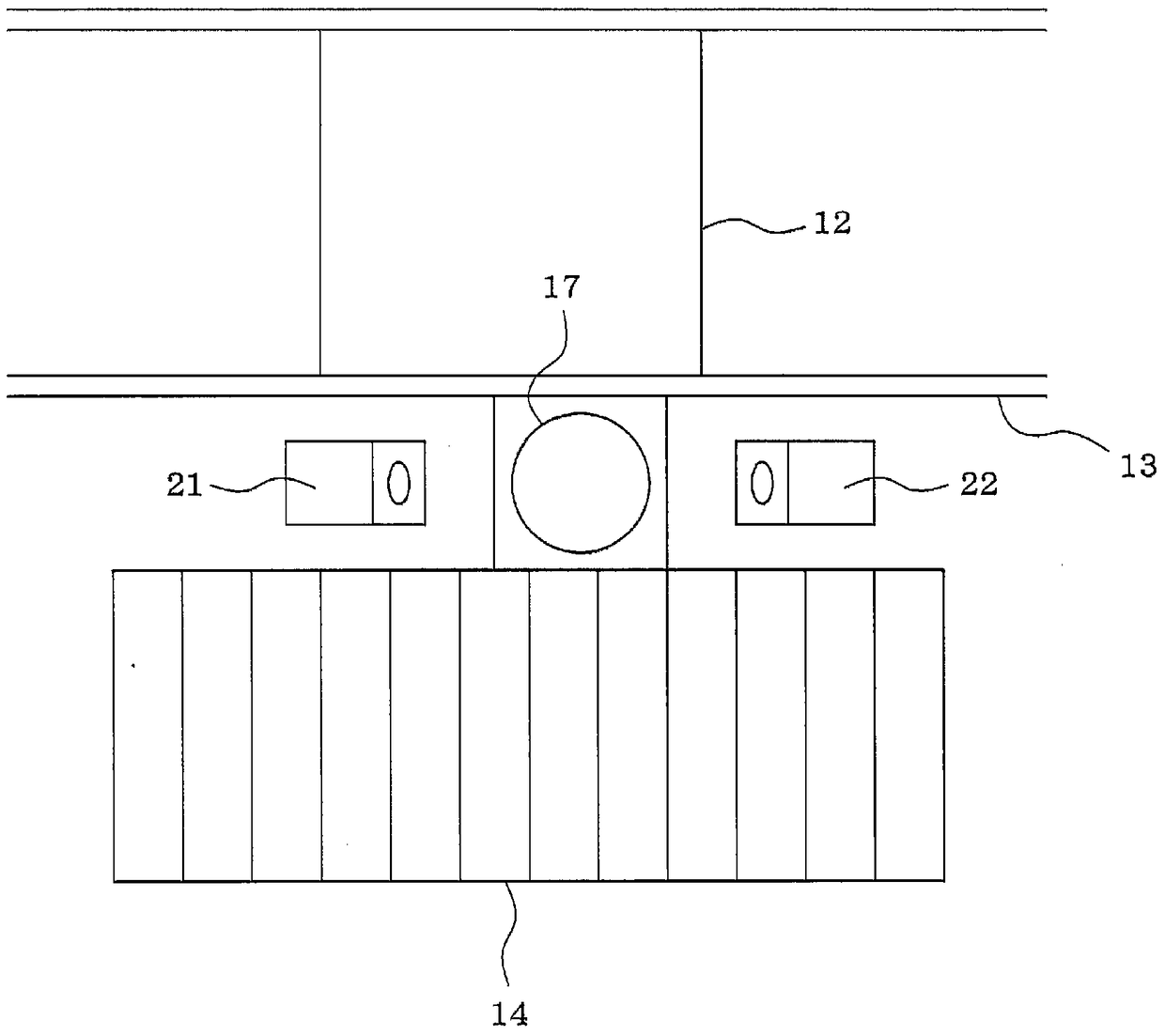

[0023] Such as figure 1 As shown, the component mounting machine is provided with: a conveyor 13 for conveying the circuit board 12, a supply component 16 (refer to figure 2 ), a component supply device 14 such as a tape feeder, and a suction nozzle 15 that holds a component 16 supplied from the component supply device 14 (see figure 2 ) mounting head (not shown), a head moving device (not shown) that moves the mounting head in XY, and the like.

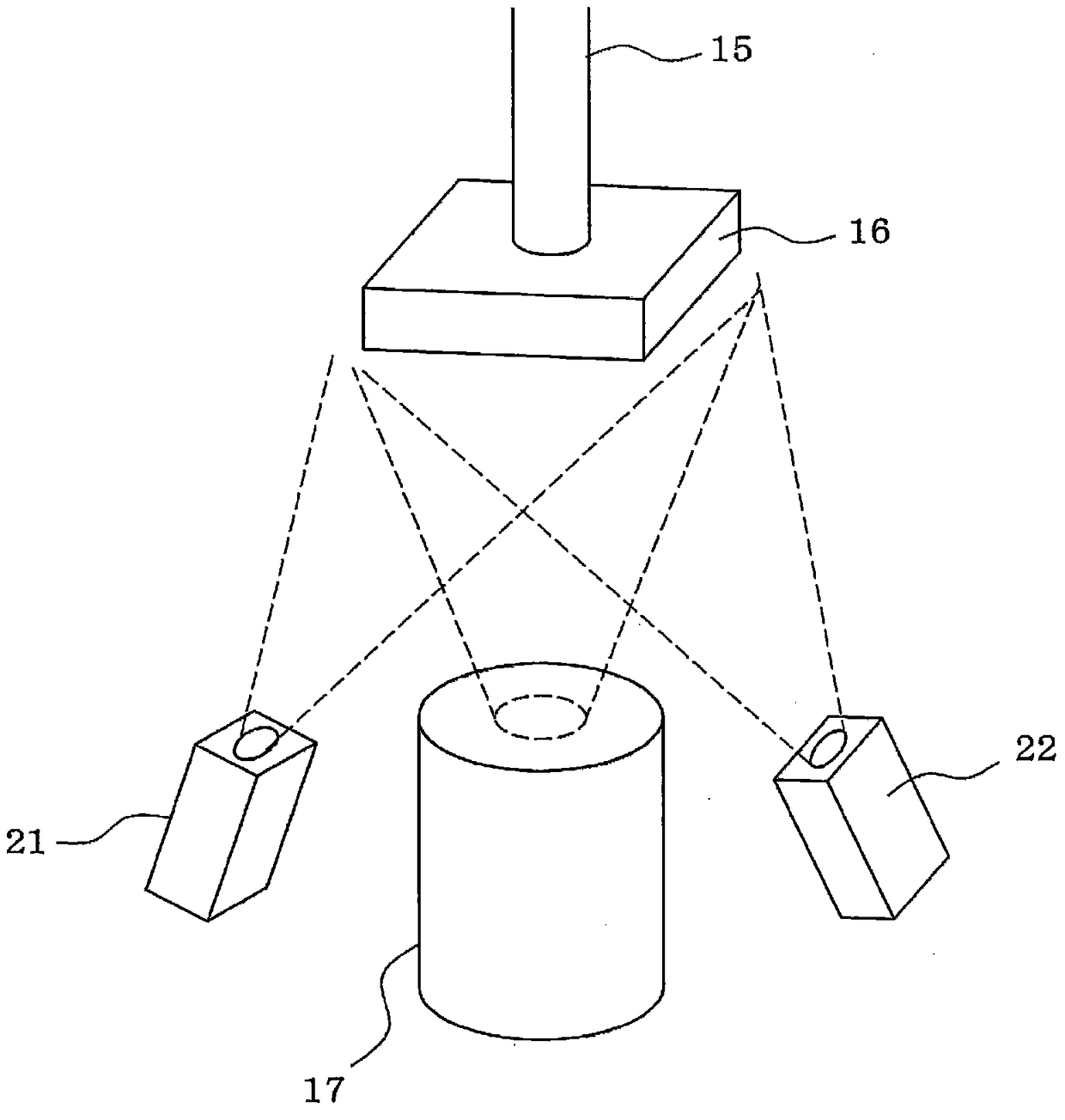

[0024] Between the component supply device 14 and the conveyor 13, such as figure 2 As shown, the camera 17 which photographs the component 16 sucked by the suction nozzle 15 from below is installed upwards. Two light pattern projection devices 21 and 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com