Self-cleaning device for bridge expansion joints

A self-cleaning, expansion joint technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as cover plate damage, long cycle, affecting normal function of expansion joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

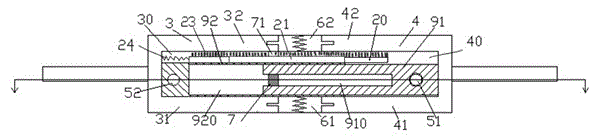

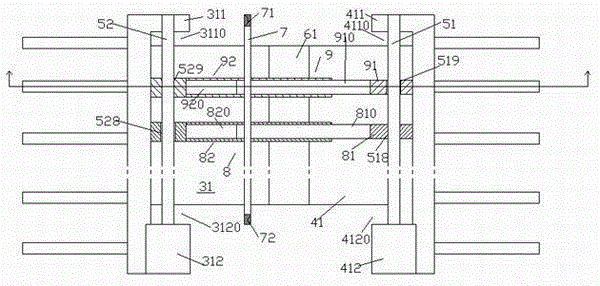

[0010] combined with Figure 1-2 , to explain the present invention in detail.

[0011] According to the self-cleaning device of the bridge expansion joint in the embodiment, the self-cleaning device comprises a left half-frame 3, a right half-frame 4 and between the left half-frame 3 and the right half-frame 4 are respectively used for The upper elastic cover 62 and the lower elastic cover 61 covering the expansion joint between the left half frame 3 and the right half frame 4 on the road surface and under the road surface of the bridge are formed by the left half frame 3 and the right half frame. In the cavities 30, 40 surrounded by the half frame 4, the upper elastic cover 62 and the lower elastic cover 61, a first movable cleaning plate assembly 9 and a second movable cleaning plate assembly 8 arranged in the front and rear directions are arranged, and the The first moving cleaning plate assembly 9 and the second moving cleaning plate assembly 8 each comprise a left plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com