a buckle assembly

一种组件、扣片的技术,应用在扣件、纽扣、服饰等方向,能够解决纽扣损坏等问题,达到增加稳定牢固性、扣合力稳定又牢固的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

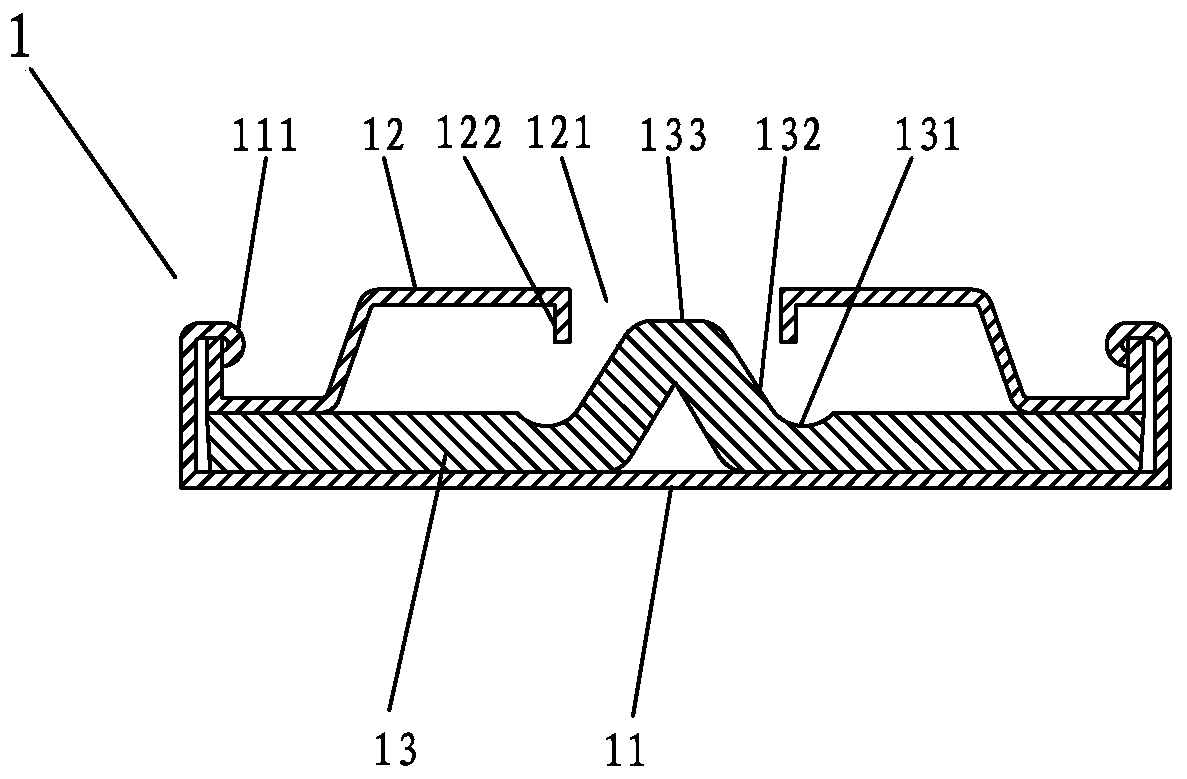

[0038] This case relates to a new buckle assembly, which has a first assembly, the first embodiment of which is as figure 1 As shown, the first component 1 includes a first buckle shell 11 , a buckle 12 and a buckle 13 .

[0039] The buckle 12 is fixedly assembled on the first buckle shell 11 , specifically, the first buckle shell 11 adopts a method of half-surrounding the edge of the buckle 12 by the folded edge 111 to realize the fixed assembly of the two. The locking card 12 is provided with a locking hole 121 . Preferably, a flange 122 is formed inside the locking hole 121 to strengthen the holding and limiting function of the locking hole 121 .

[0040] The buckle 13 is suitably disposed between the first buckle shell 11 and the buckle 12 . like figure 1 , Figure 7 As shown, an annular groove 131 is formed on the side of the buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com