Novel button

A button, a new type of technology, applied in the direction of fasteners, press fasteners, press fasteners, etc., can solve the problems of insufficient fastening force, no support part, easy to fall off, etc., to achieve compact structure design, stable positioning, and fit good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

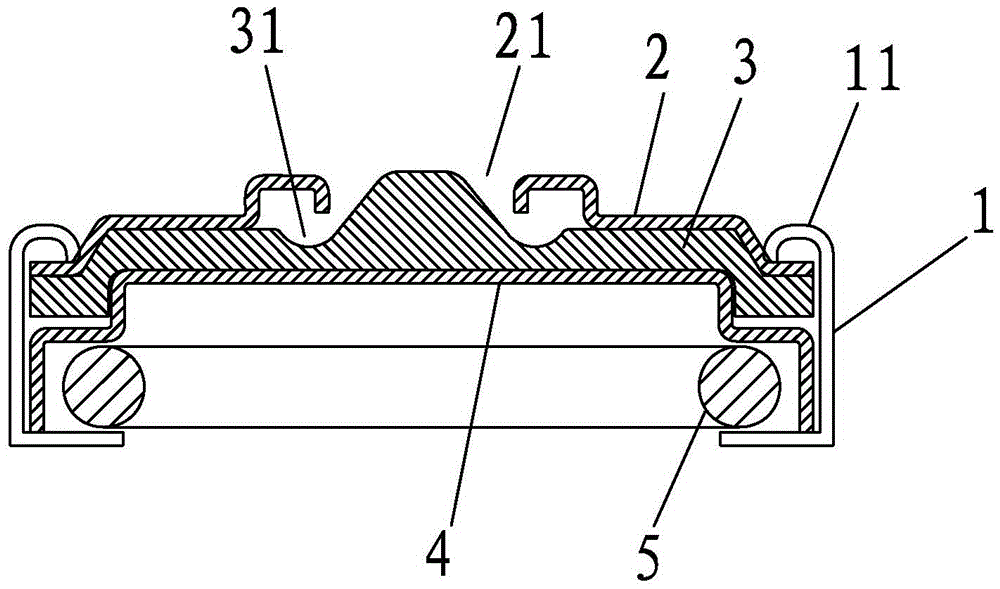

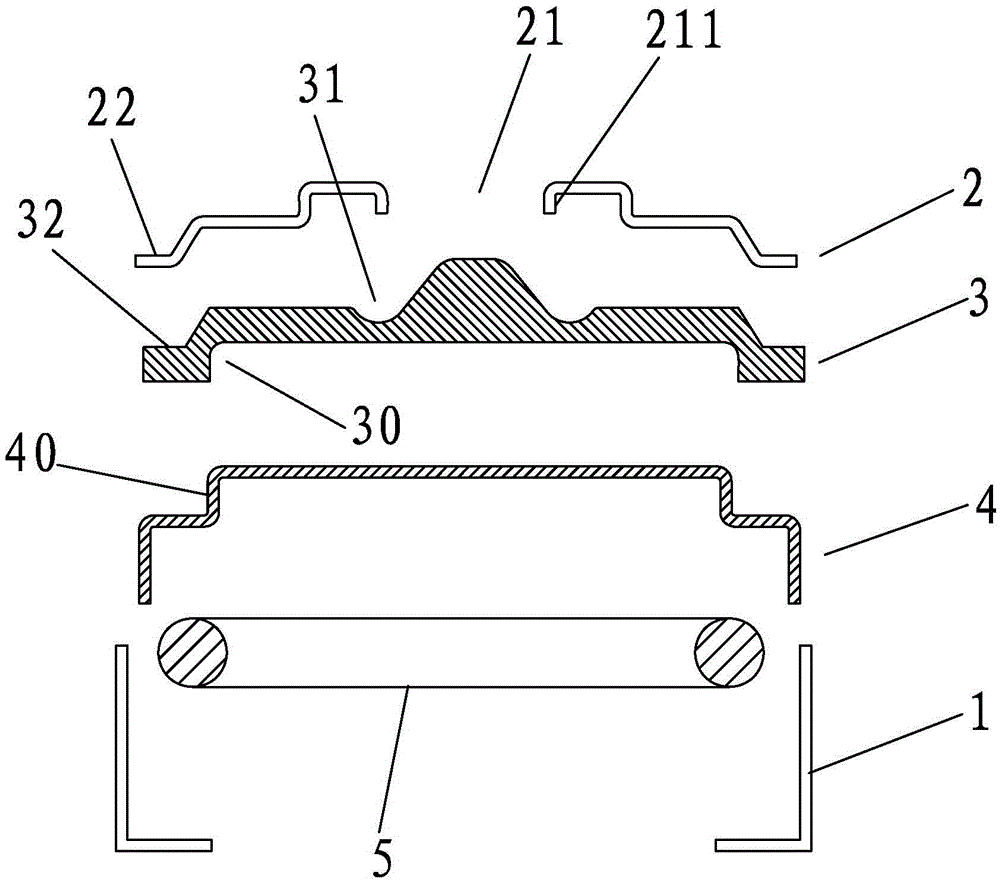

[0028] This case involves a new type of button, such as Figure 1-2 As shown, it mainly includes a buckle shell 1, a buckle cover 2, a buckle piece 3 and a buckle bottom 4. The buckle cover 2 , the buckle piece 3 and the buckle bottom 4 are closely stacked up and down sequentially, and the three are semi-enclosed and assembled by the buckle shell 1 . Copper ring 5 can be assembled in the button bottom 4 .

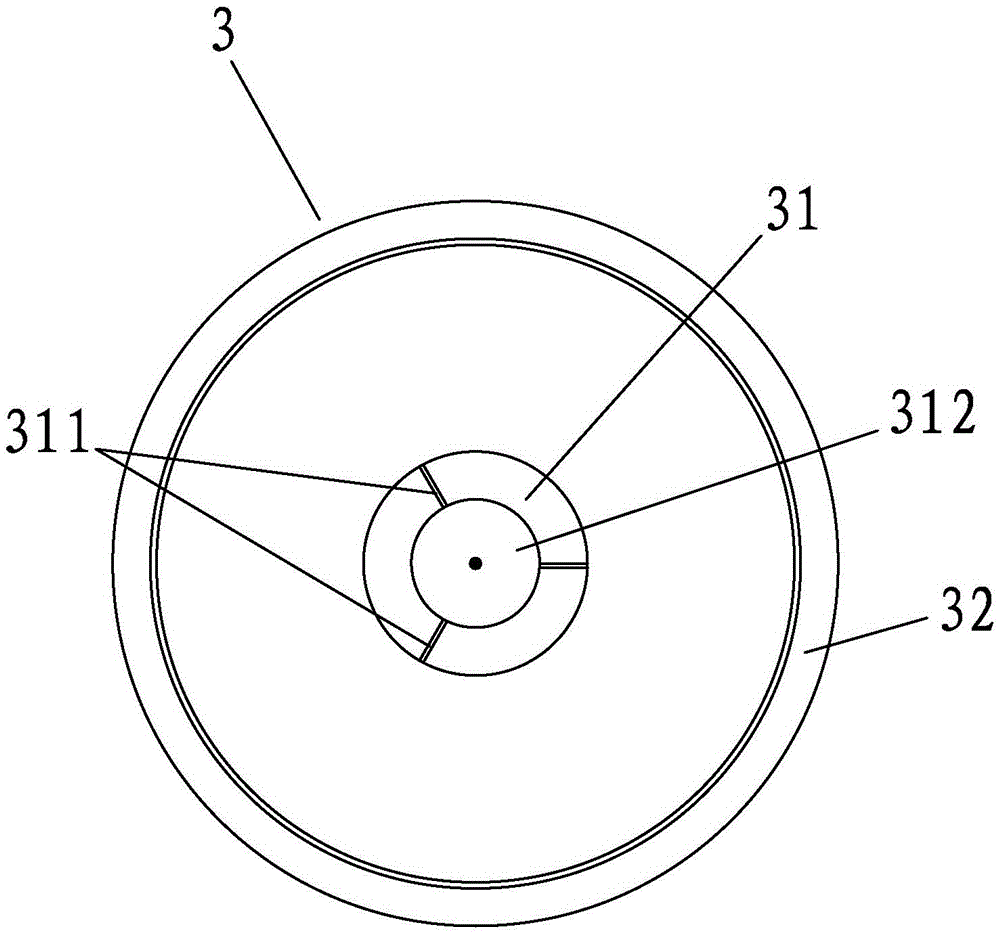

[0029] A convex step 40 is formed on the buckle bottom 4 , and the convex step 40 is preferably a circular convex column whose step surface is close to its own edge. The corresponding buckle 3 is formed with a concave step groove 30 for matching and embedding the convex step 40, and the buckle 3 is nested and matched with the concave step groove 30 by means of the convex step 40 to realize a tight and stable assembly with the buckle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com