Meta-material film for left-hand circular polarization conversion

A technology of left-handed circular polarization and material thin film, which is applied in the field of optical communication, can solve the problems of low control precision, high insertion loss, incident angle sensitivity manufacturing process, etc., and achieve high output beam quality, simple structure and pattern, and good development prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

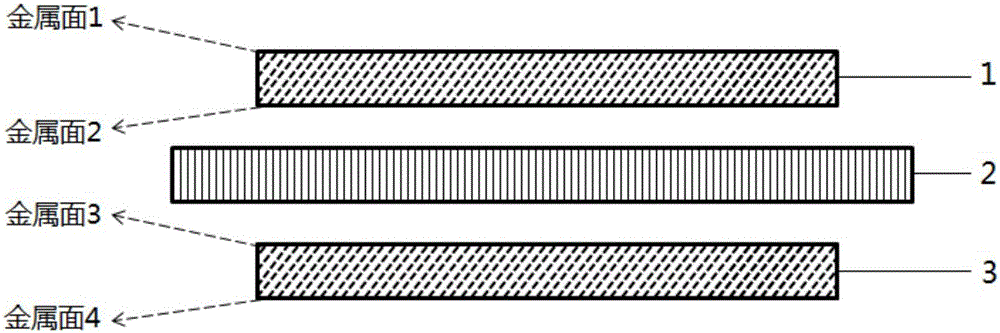

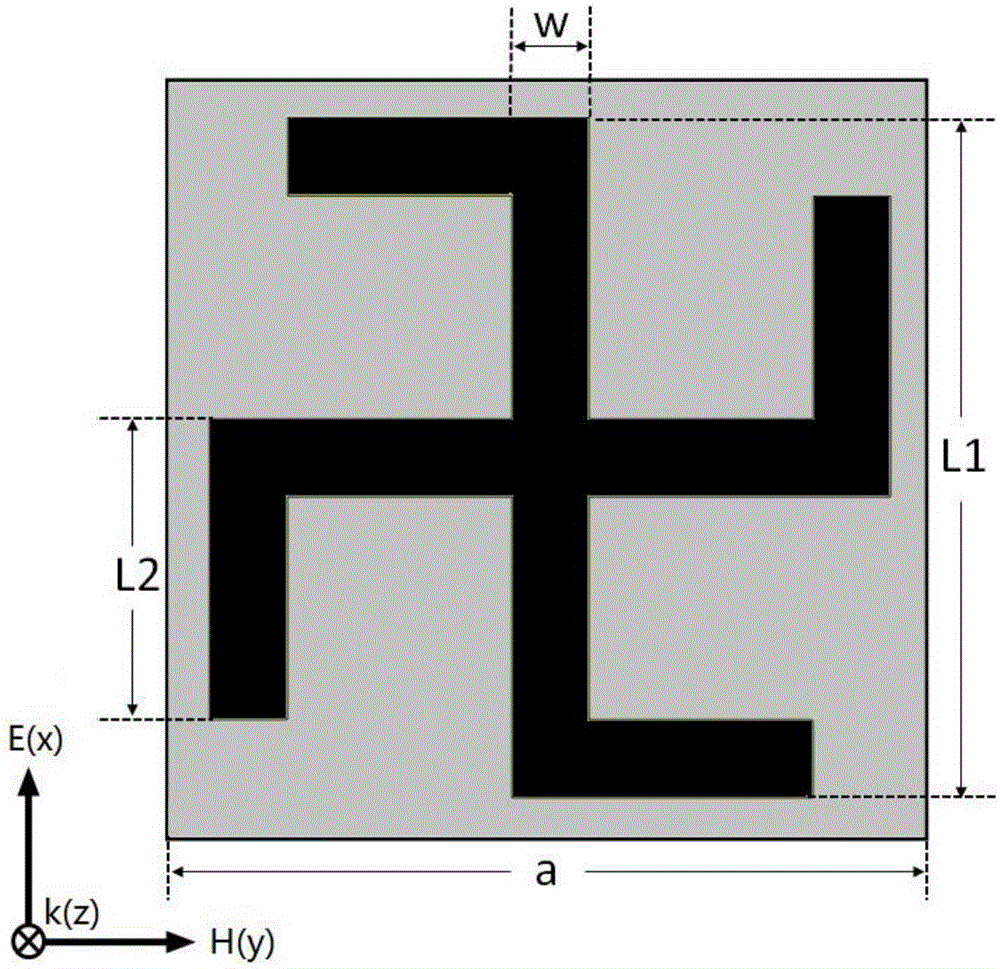

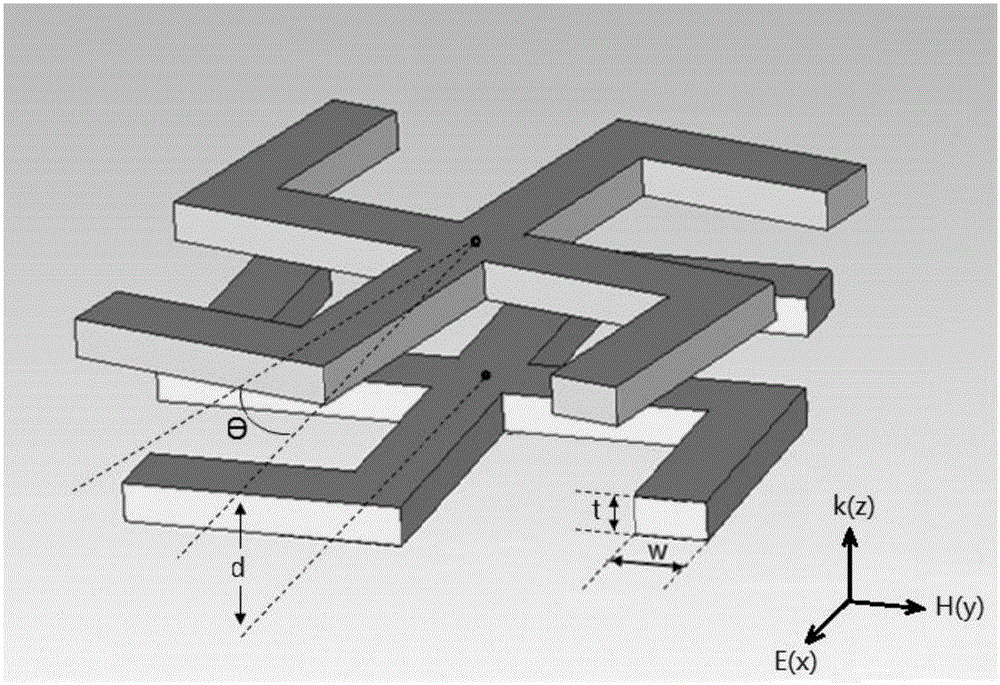

[0035] Such as figure 1 As shown, the metamaterial film for left-handed circular polarization conversion is a metamaterial structure in the optical frequency band, which includes a metal microstructure layer 1 (the first metal microstructure layer), a dielectric substrate layer 2, and a metal microstructure layer 3 (the second metal microstructure layer). structure layer), metal microstructure layer 1 (the first metal microstructure layer) and metal microstructure layer 3 (the second metal microstructure layer) are attached to both sides of the dielectric substrate layer 2, and the two metal microstructure layers 1 and 3 (the second metal microstructure layer) One metal microstructure layer and the second metal microstructure layer) are divided into four metal surfaces, that is, the upper surface of the metal microstructure layer 1 is the metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com