Proceeding in connection with stone production and a plant for the proceeding

A stone and stone technology, which is applied in the field of natural stone to produce disc-shaped stone products, can solve the problems of difficult recycling and reuse, consumption of impregnating agent, etc., and achieve the effect of simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

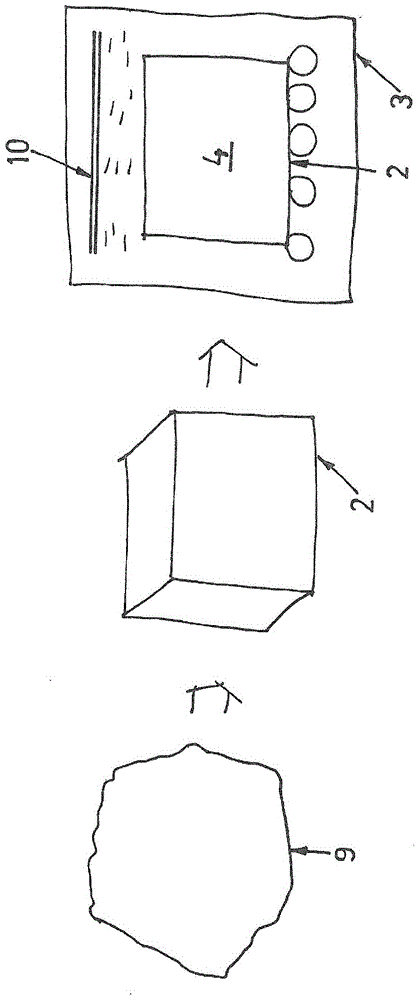

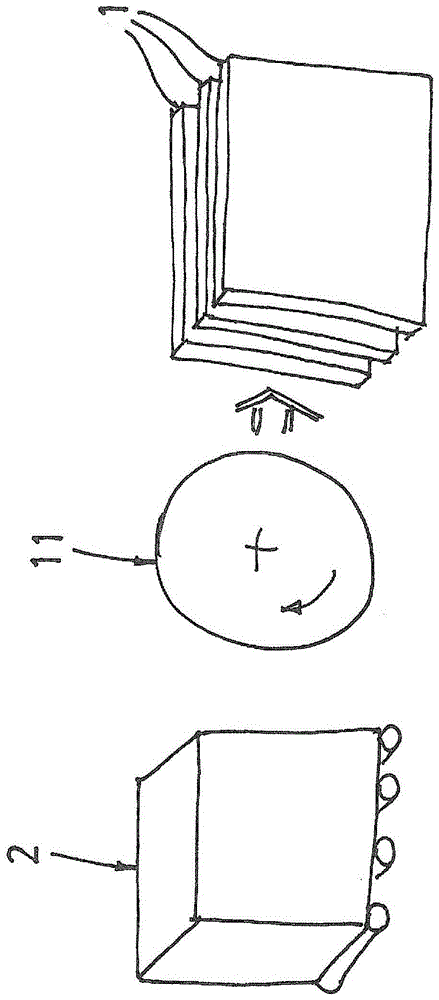

[0014] The present invention relates to a method for producing a slab-shaped stone product 1 from natural stone 2 , comprising removing, in thinner slabs 1 , the stresses occurring in said stone 2 . The method implies that the stone 2 is dried so that a stress relief of the stone 2 is obtained. According to the invention, the stones 2 are dried therein from the inside by using a microwave dryer 3 in which the stones 2 remain for a certain period of time so as to obtain their stress relief.

[0015] By housing the stone 2 inside the microwave oven 3 for a certain time, the entire stone 2 is efficiently dried from the inside 4 .

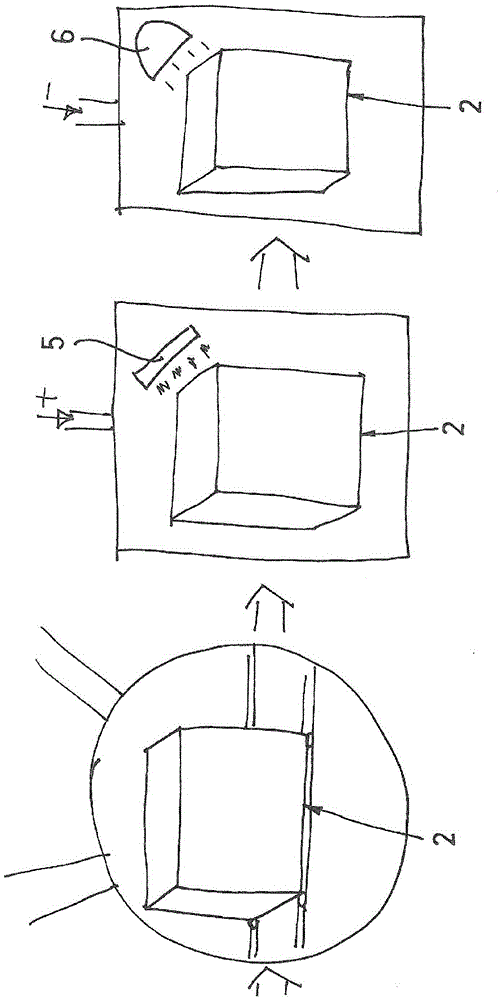

[0016] After drying in said microwave oven 3, the stones 2 are heated to at least 100° C. for a certain time. Preferably, the stone 2 is further heated and dried by using infrared radiation 5 of the stone 2 .

[0017] After said heating of the stone 2, said stone 2 is cooled to room temperature of about 18 to 25°C. Acquiring this cooling varies quic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap