Blocking elements for ball trap screen

A technology of blocking elements and screen tubes, applied in multiple fields of blocking elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is a plurality of blocking elements for enhancing the movement of the cleaning balls through the ball catch screens of the ball catcher in a closed fluid flow system.

[0026] The principles and operation of the blocking elements used in accordance with the present invention with catch screens may be better understood with reference to the accompanying drawings and the accompanying description.

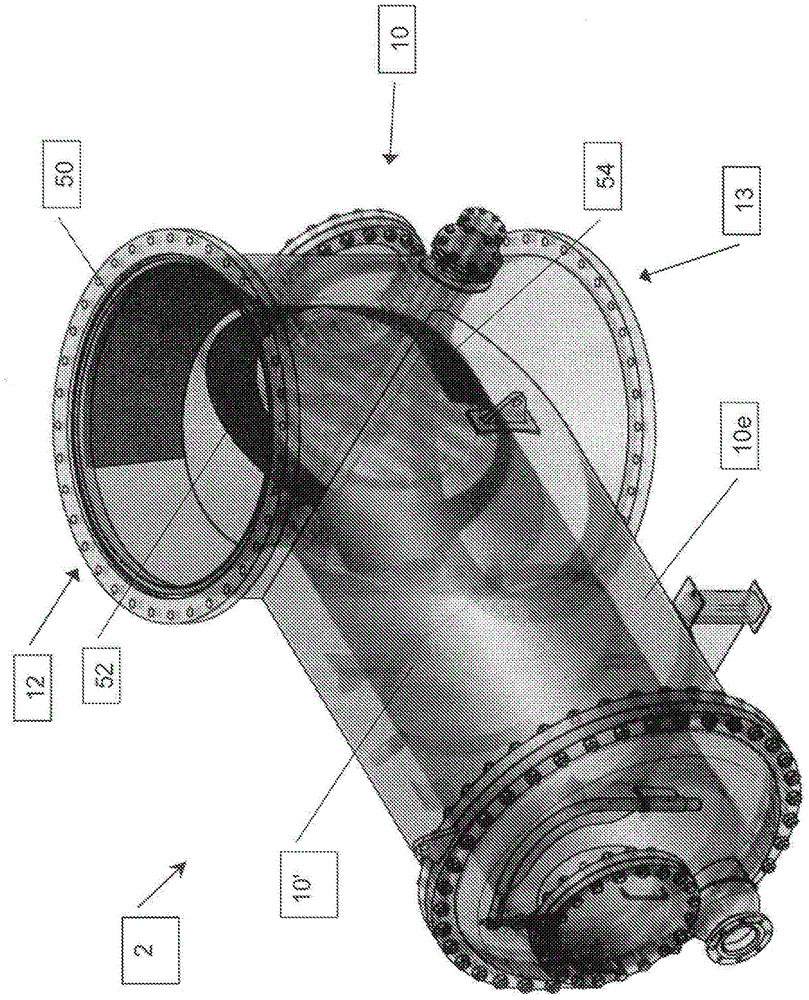

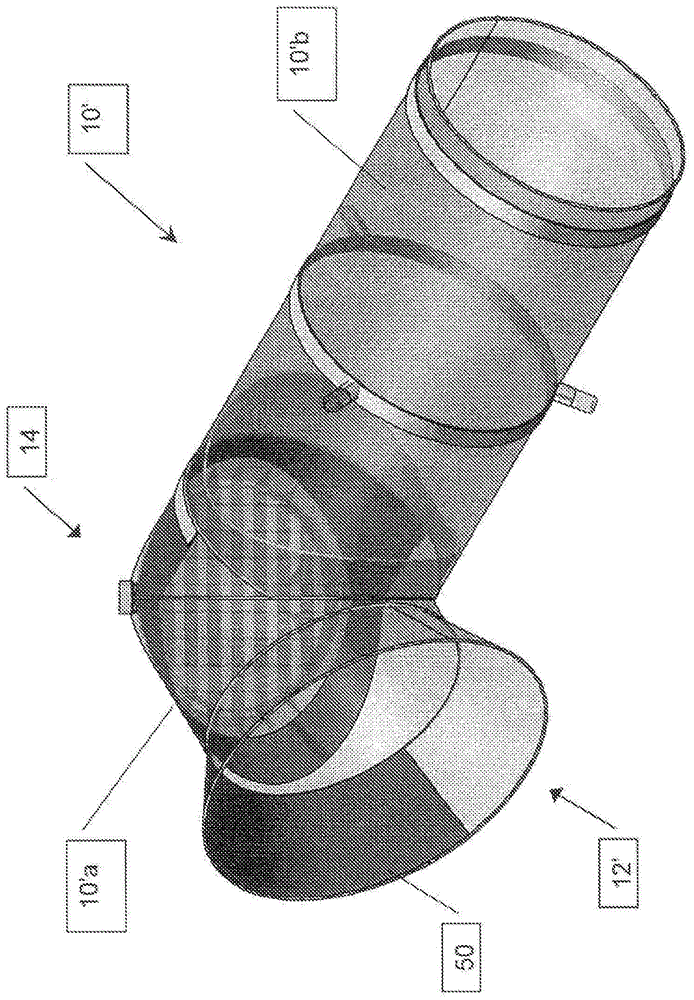

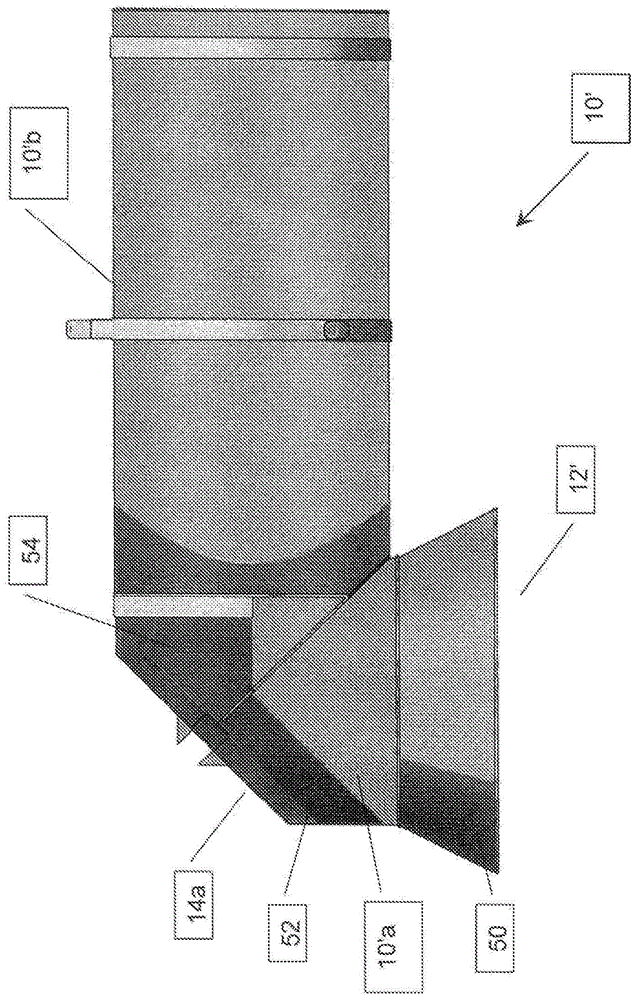

[0027] Now please refer to the attached picture, figure 1 A transparent view of a "T"-shaped ball catcher 2 is shown, which has a ball catcher housing 10 with a water inlet 12, a water outlet 13 and a ball catcher extension 10e. Also shown is a ball catch screen 10' deployed within the ball catch housing 10. It can be understood that, in such a plurality of ball catchers, the main fluid flow path is located at the water inlet 12, a water outlet 13 and guides the plurality of cleaning balls through a secondary fluid flow path to the Between the three in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com