Coil winding device and winding method thereof

A winding device and winding technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problem that flat winding machines cannot perform flat winding coils, etc., so as to reduce equipment procurement investment, save scientific research and production costs , Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

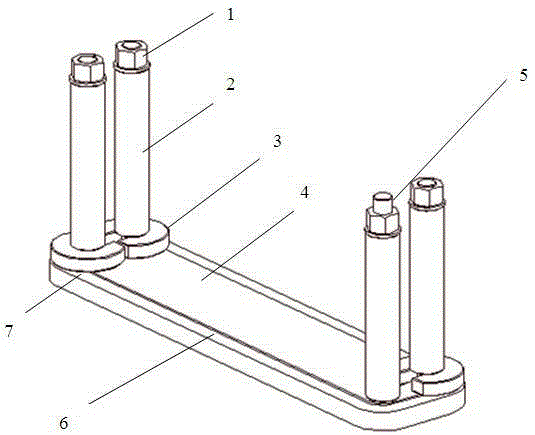

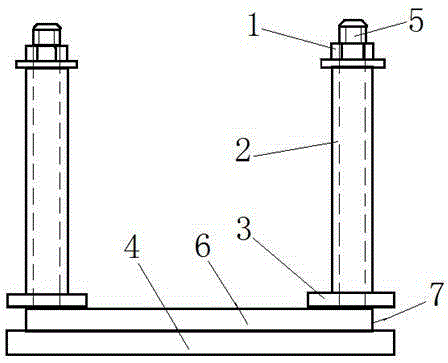

[0024] As shown in the drawings, a winding device for an edgewise coil includes a base 4 , a step 6 , a pressing plate 3 , a screw 5 , a sleeve 2 and a nut 1 . The base 4 is a long ring, and the edge of the upper plane is provided with a concave step 6, and the lower plane is fixedly installed on the rotary disk of the ordinary flat winding winding machine, and the rotary disk drives the base to rotate, and the coil winding is realized under manual operation. Four screw rods 5 are arranged at the corners of the base 4 , the sleeve 2 passes through the screw rods 5 , and the rear end can be fastened with a nut 1 . The pressing plate 3 is provided with a U-shaped notch, and the pressing plate 3 is clamped on the screw rod 5, and can also be taken out flexibly. The pressing plate 3 is annular, and the number is 3. It cooperates with the step 6 of the base 4 to form a limiting groove 7, and the flat copper wire is limited by the limiting groove 7 during operation. The front end o...

Embodiment 2

[0027] The basic structure of the second embodiment is the same as that of the first embodiment, except that the base 4 is rectangular, and the number of the pressing plates 3 is four, and each screw 5 is pressed with a fixed sleeve 2, and each fixed sleeve 2 A pressing plate 3 is pressed below, and the pressing plate 3 is rectangular. There is a slot on the pressing plate 3 , and the slot is locked on the screw rod 5 , and the pressing plate 3 is tightened and fixed by the fixing sleeve 2 through the nut 1 sleeved on the screw rod 5 .

[0028] The winding method is the same as that of Embodiment 1, and will not be described here again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com