Parallel robot

A robot and parallel technology, applied in the direction of manipulators, program control manipulators, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

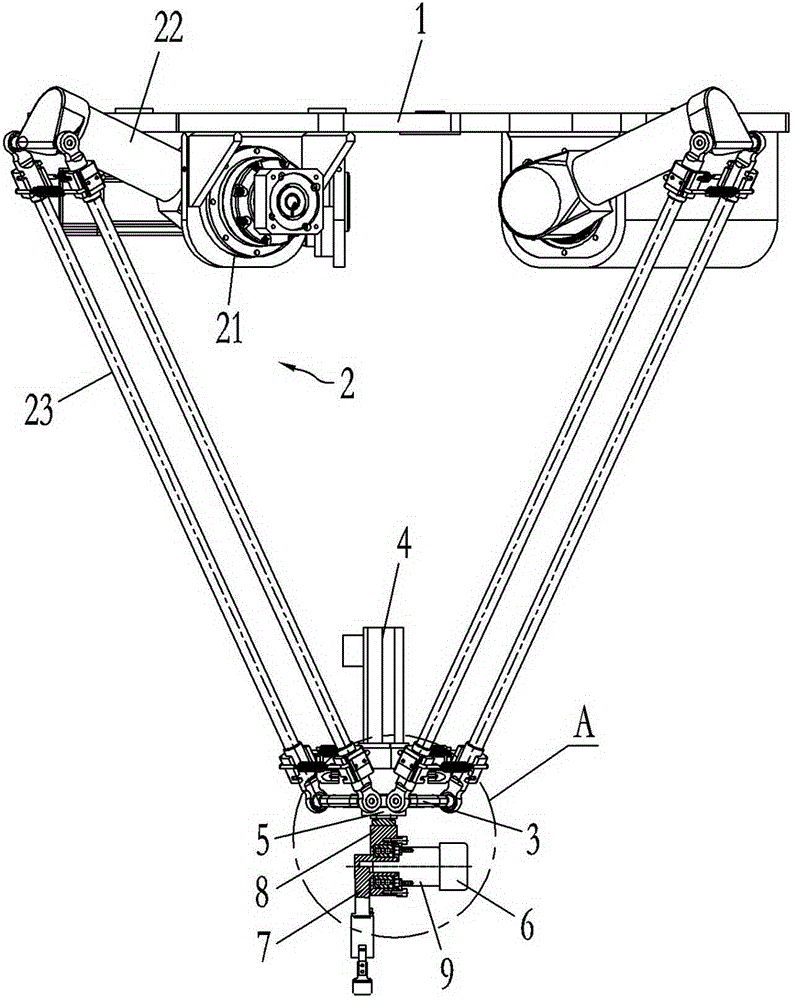

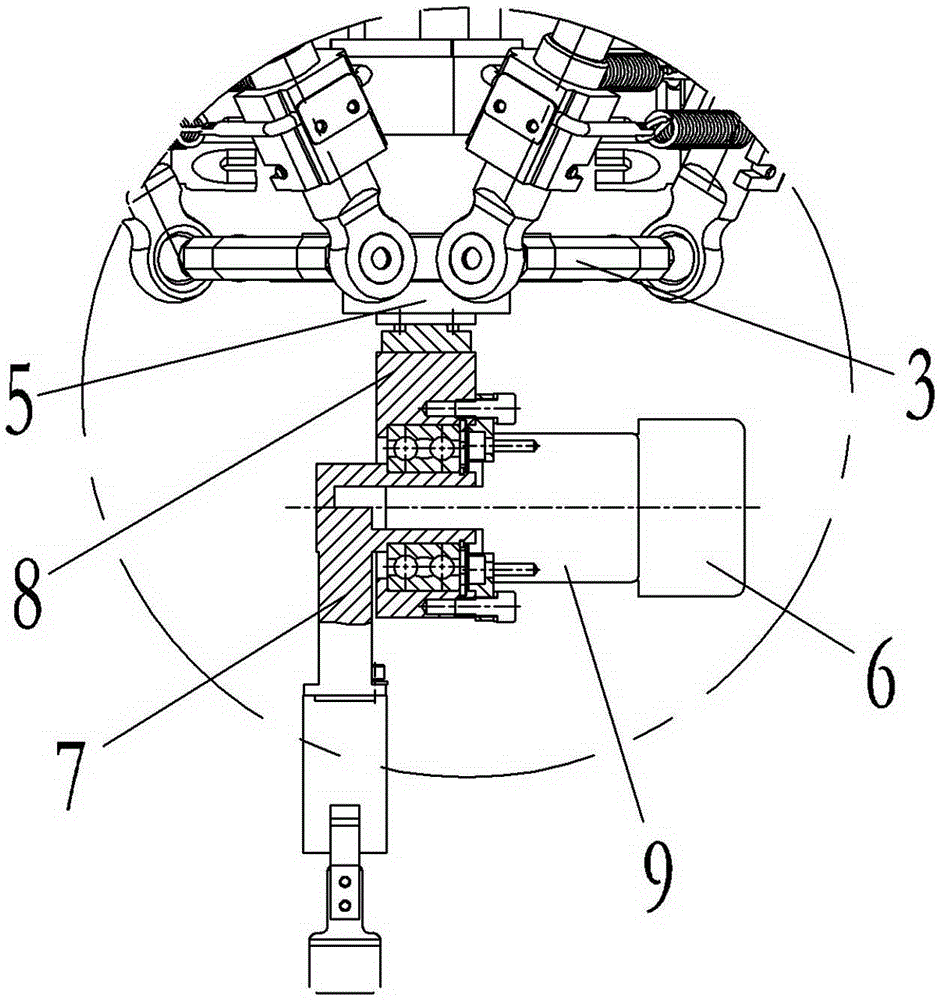

[0011] like figure 1 , figure 2 As shown, the parallel robot of the present invention includes a moving structure 2 installed on the base 1 and a rotating structure that drives the turntable to rotate around the Z axis, wherein the moving structure 2 can realize the movement of the gripper in the X-axis, Y-axis and Z-axis The mobile structure 2 includes at least three first driving devices 21 fixed on the base 1, the first driving devices 21 may be servo motors or rotary cylinders, and the rotating shafts of each first driving device 21 are respectively fixedly connected with rocker arms 22. When the rotating shaft rotates, the rocker arm 22 can be driven to swing in a vertical plane around the axis of the rotating shaft. The end of each rocker arm 22 away from the rotating shaft is connected to the upper end of the connecting rod 23 through a joint bearing, and the lower ends of all connecting rods 23 are connected through a joint bearing. Commonly connected to the gripper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com