Cable stripping tool

A tool and workpiece technology, applied in the field of stripping tools, can solve problems such as no stripping stroke, and achieve the effects of improving operational safety, reliable insurance, and simplifying assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

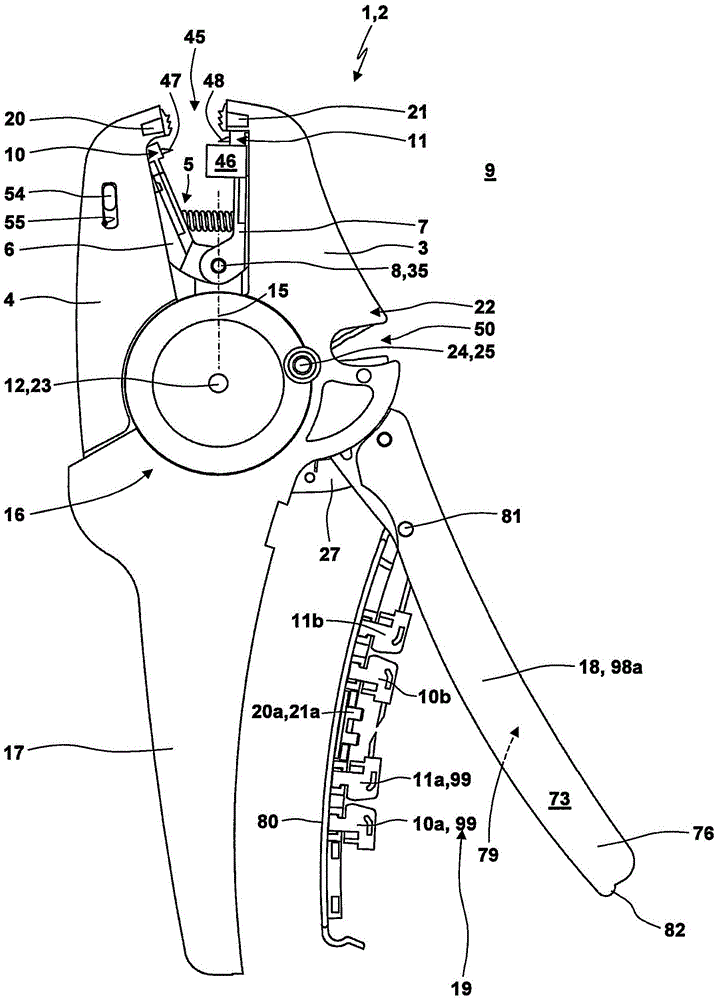

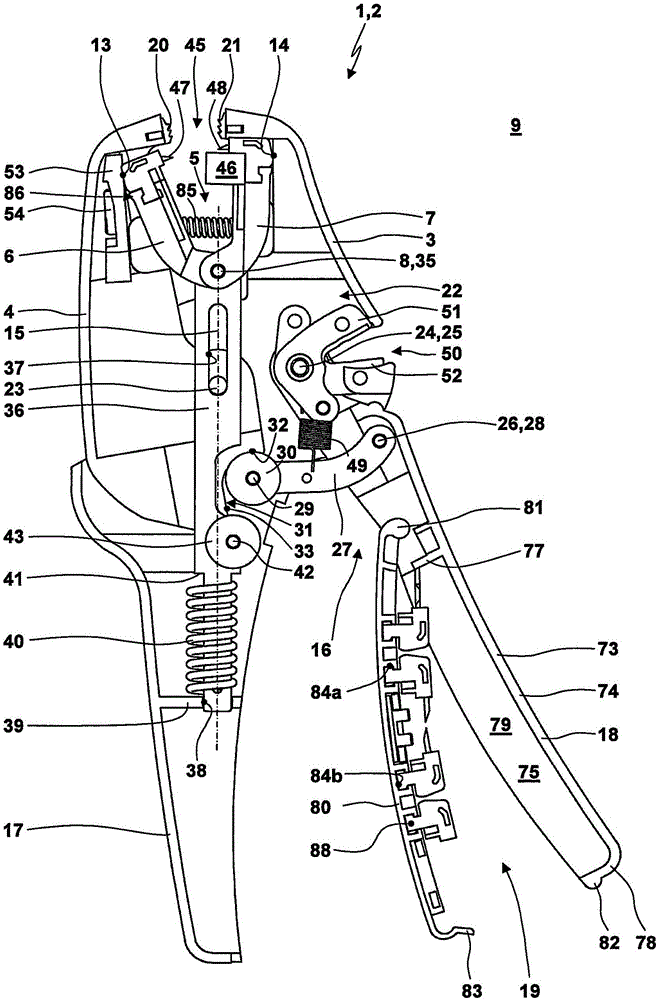

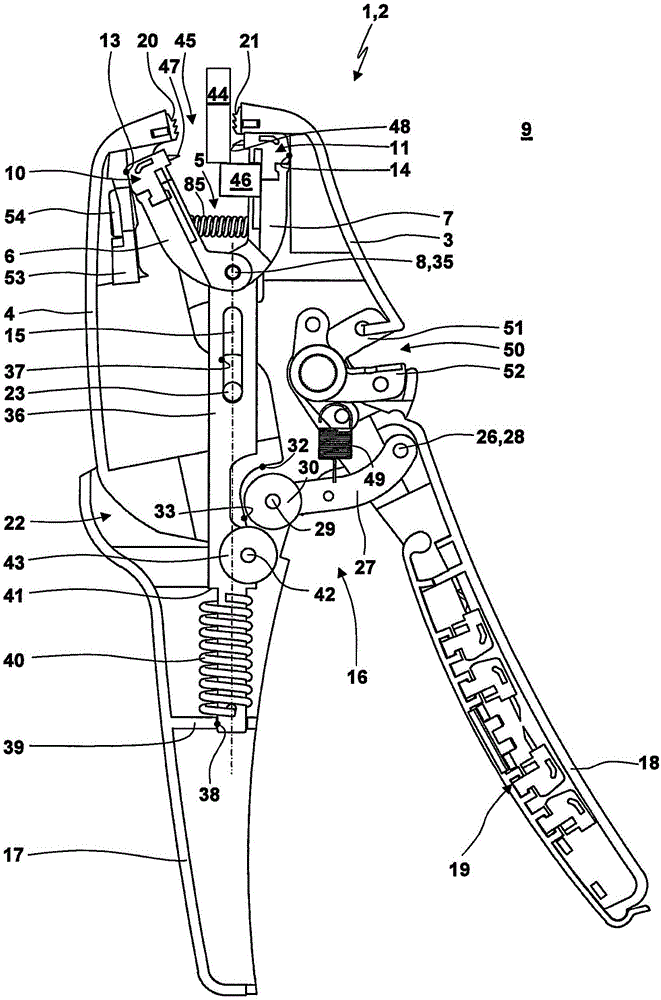

[0065] In these figures a stripping tool 1 is shown in the form of a manually actuated stripping tongs 2 without the invention being restricted to manually actuated stripping tongs 2 . The stripping tongs 2 have two jaw plates 3 , 4 . A stripping unit 5 is accommodated between the two jaws 3 , 4 , which is constructed with two stripping jaws 6 , 7 . The stripping splints 6, 7 are pivotable in an end region via a joint 8 in a direction parallel to the figure 1 Pivot planes 9 oriented in the plane of the drawing are connected to one another so as to be pivotable. The peeling jaws 6 , 7 each carry a cutting element 10 , 11 in their free end region. The jaw plates 3 , 4 are pivotably connected to one another in the pivot plane 9 via a joint 12 . The pivoting of the jaws 3 , 4 together occurs due to the contact via the jaws 3 , 4 with the contact surfaces 13 , 14 of the exfoliation jaws 6 , 7 and / or the cutting elements 10 , 11 accompanied by the pivoting of the exfoliation jaws...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com