Defect inspection system and film production apparatus

A defect inspection and photographing device technology, applied in measuring devices, using optical devices, controlling lamination, etc., to achieve the effect of suppressing false reports of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

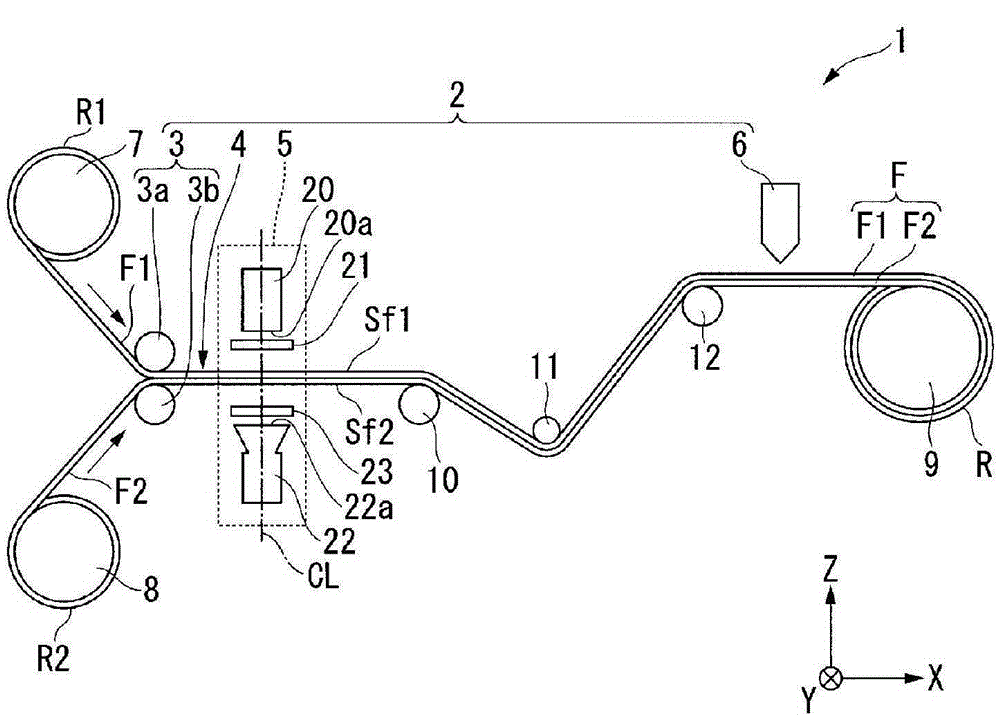

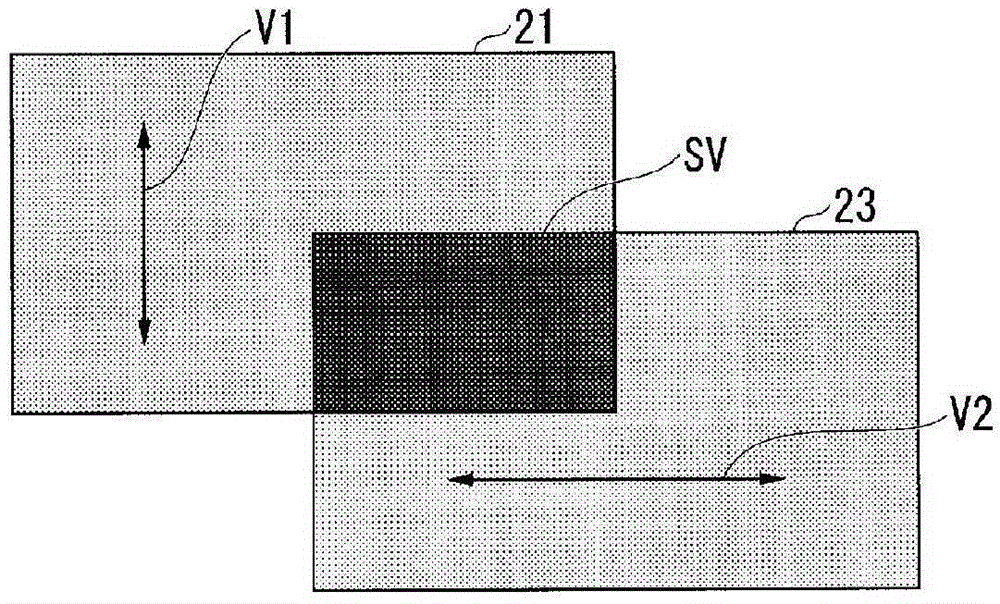

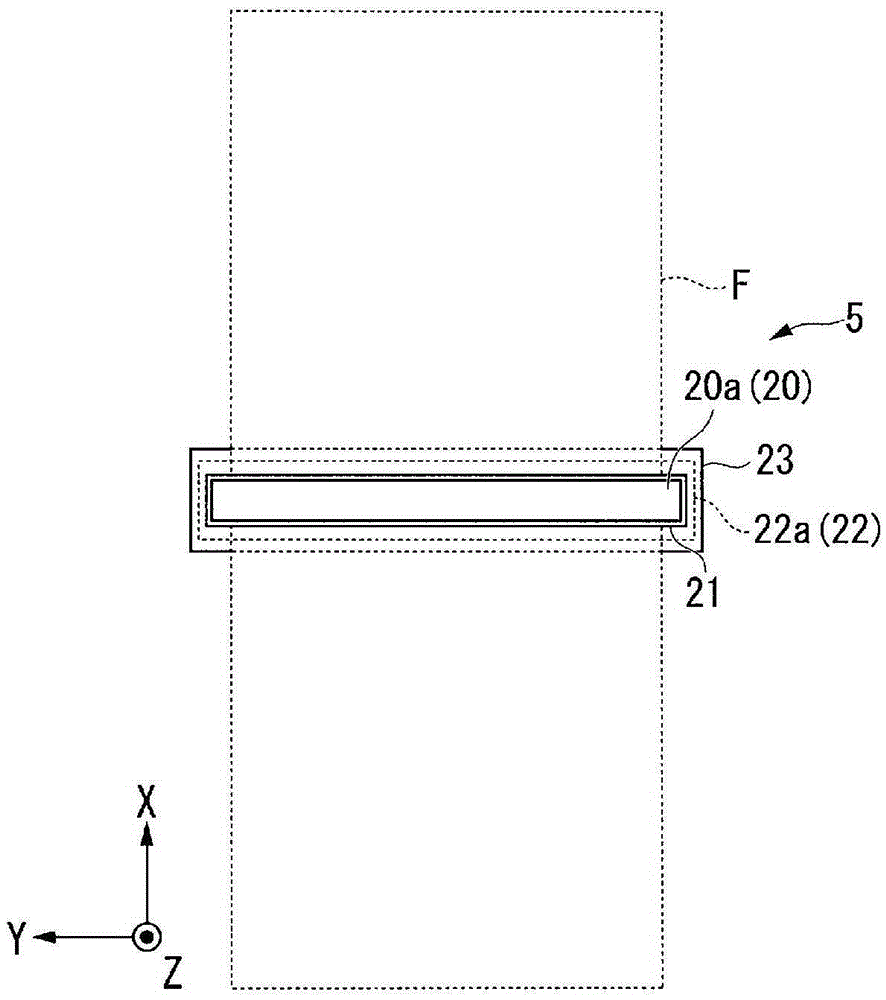

[0031] figure 1 It is a side view which shows the film manufacturing apparatus 1 which concerns on 1st Embodiment of this invention. exist figure 1 In , reference numeral Sf1 is the upper surface of the film F, and is the surface on the first film F1 side. Reference numeral Sf2 is the lower surface of the film F, and is a surface on the second film F2 side.

[0032] In the following description, an XYZ rectangular coordinate system is set as needed, and the positional relationship of each member is demonstrated with reference to this XYZ rectangular coordinate system. In the present embodiment, the conveying direction of the strip-shaped film is defined as the X direction, the direction (the width direction of the long film) perpendicular to the X direction in the plane of the film is defined as the Y direction, and the direction perpendicular to the X direction is defined as The direction perpendicular to the Y direction is defined as the Z direction.

[0033] Such as fi...

no. 2 approach

[0083] Next, use Figure 6 ~ Figure 9 A second embodiment of the present invention will be described.

[0084] Figure 6 It is a side view showing the film manufacturing apparatus 101 according to the second embodiment of the present invention.

[0085] Such as Figure 6 As shown, the film manufacturing apparatus 101 of this embodiment differs from the film manufacturing apparatus 1 of the first embodiment in that the first film F1a is a polarizer, and the defect inspection apparatus 105 includes a light source 20 arranged On the polarizer F1a side of the film Fa; the photographing device 22, which is arranged on the second film F2 side of the film Fa; and the polarizing filter 123, which is arranged on the optical path between the photographing device 22 and the film Fa . For other structures that are the same as those of the first embodiment, the same reference numerals are attached, and detailed description is omitted.

[0086] The film Fa is a tape-shaped film includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com