A three-cavity multi-layer welded front longitudinal beam

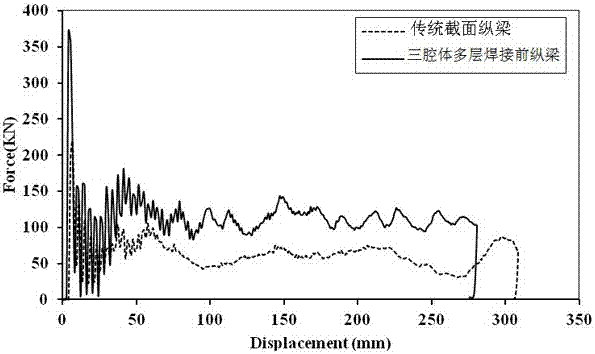

A front longitudinal beam and three-cavity technology, which is applied to the substructure, transportation and packaging, and vehicle components, can solve the problems of high vehicle acceleration, reduced design margin, and insufficient energy absorption to meet the requirements of light weight and Energy absorption requirements, improving crushing force and the effect of energy absorption index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

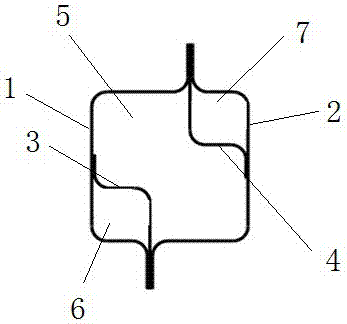

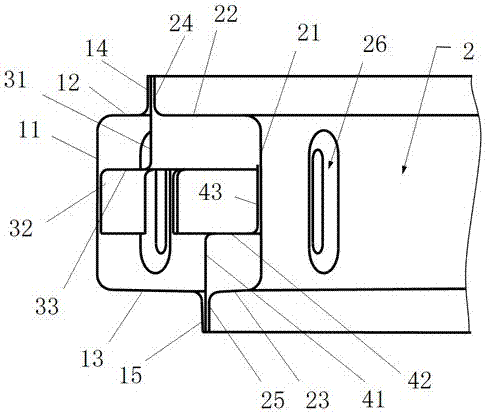

[0018] Figure 1 to Figure 2 The reference numerals in the figure are: the first longitudinal beam 1; the second longitudinal beam 2; the first reinforcing plate 3; the second reinforcing plate 4; the first frame 5; the second frame 6; the third frame 7.

[0019] Such as Figure 1 to Figure 2 As shown, a three-cavity multi-layer welded front longitudinal beam includes a first longitudinal beam 1, a second longitudinal beam 2, a first reinforcing plate 3 and a second reinforcing plate 4, wherein the first longitudinal beam 1 and The second longitudinal beam 2 forms a closed first square frame 5, and one of the corners of the first reinforcing plate 3 and the first square frame 5 forms a closed second square frame 6, and the second The reinforcing plate 4 and the other corner of the first frame 5 form a closed third frame 7, the second frame 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com