Valve with fail-safe mechanism

A fail-safe, valve body technology, applied in safety valves, failure prevention, engine cooling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

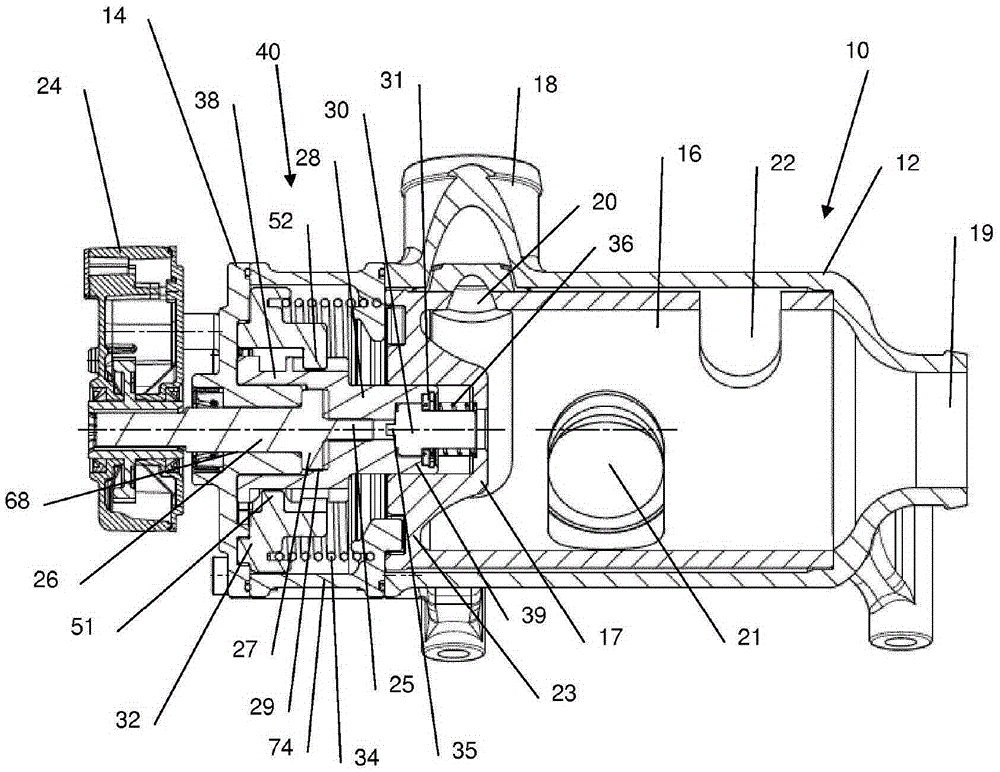

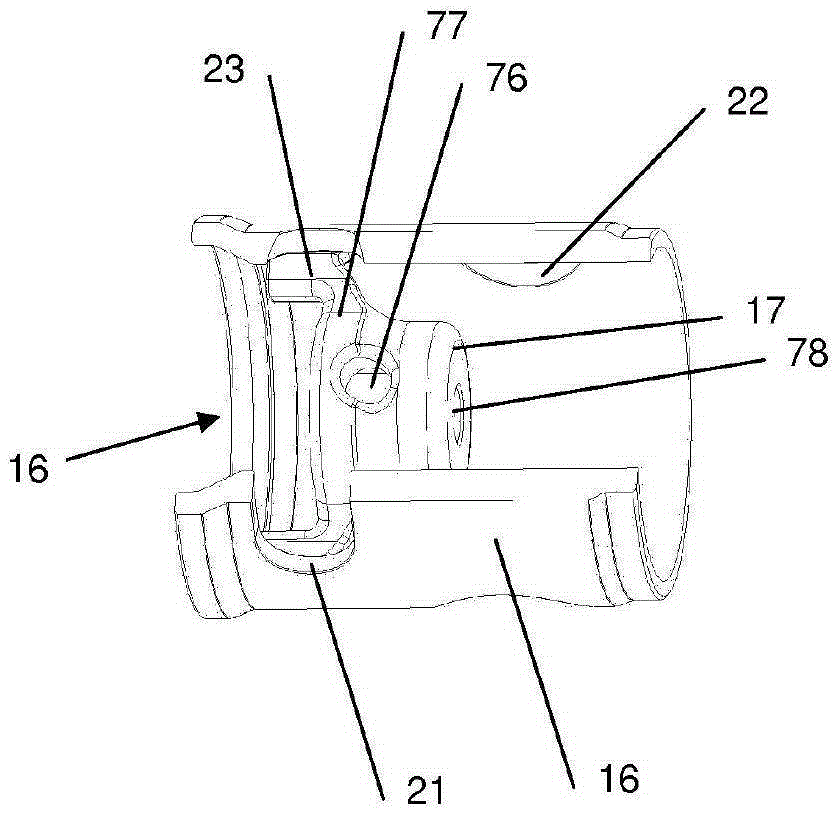

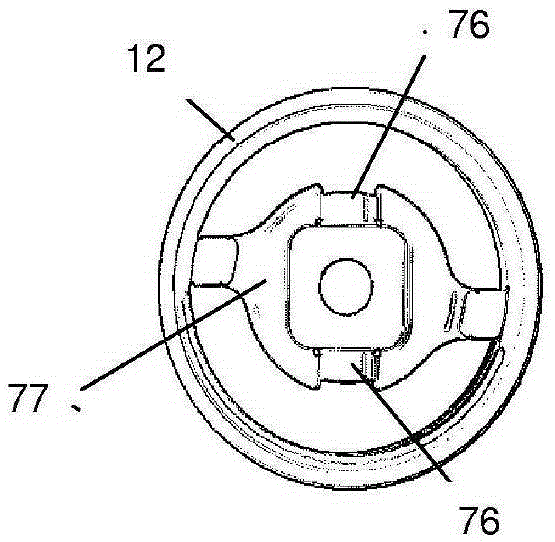

[0031] according to figure 1 , the valve 10 has a substantially hollow-cylindrical housing section 12 with an outlet 19 and a plurality of inlets 18, of which only one, however, is visible. The valve housing 12 rotatably accommodates in its interior a likewise substantially hollow-cylindrical valve body 16 , wherein the valve body 16 has a plurality of inlet channels 20 , 21 , 22 , which according to the The rotational position of the valve body 16 of the respective inlet 18 is aligned such that the coolant flow between the respective inlet 18 and outlet 19 can be varied as a function of the rotational position of the valve body 16 .

[0032] Furthermore, the valve 10 has an adjusting actuator 24 , the shaft 26 of which is indirectly and releasably connected to the valve body 16 for rotating it. In this case, the actuator shaft 26 extends through the opening 68 of the housing cover 14 , which is mounted on a substantially hollow-cylindrical housing body 74 which accommodates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com