Electrical terminal and method

A terminal, electrical contact technology, applied in the direction of conductive connection, circuit, connection, etc., can solve the problems of inability to screw in the wire, difficult assembly, etc., and achieve the effect of reliable contact, flexible connection scheme, and small operating stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

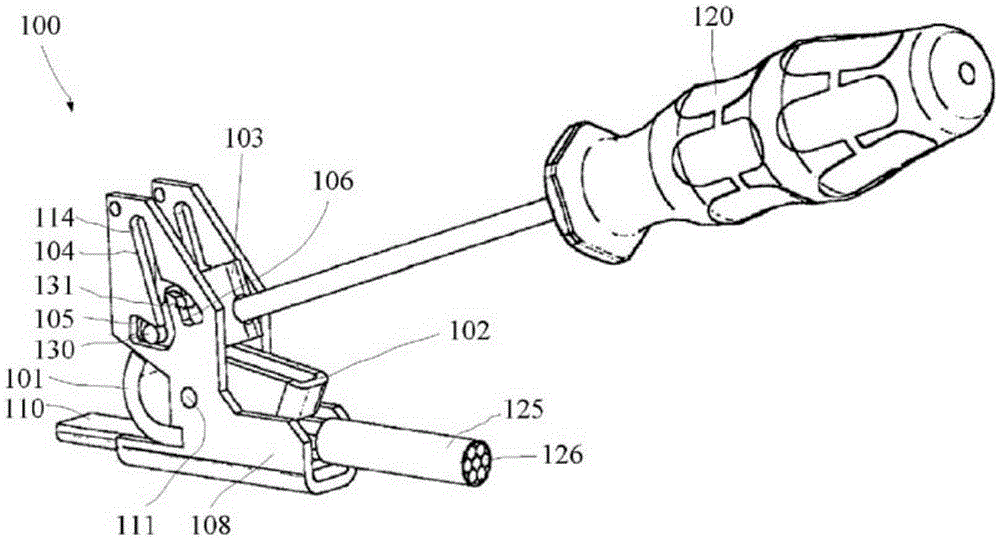

[0043] figure 1 A schematic perspective view of an electrical connection terminal 100 comprising an inserted cable 125 having a plurality of conductors 126 is shown. Here, a tool 120 in the form of a screwdriver is inserted into the lever 103 of the electrical terminal 100 in order to switch the electrical terminal 100 into the clamped state 145 .

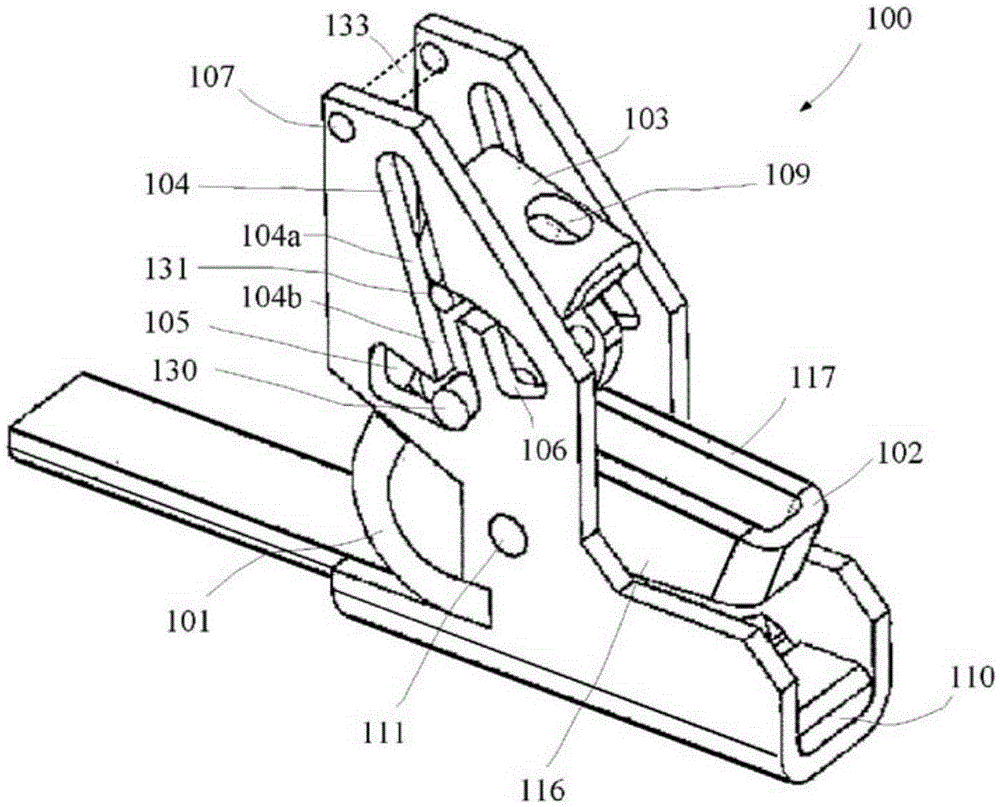

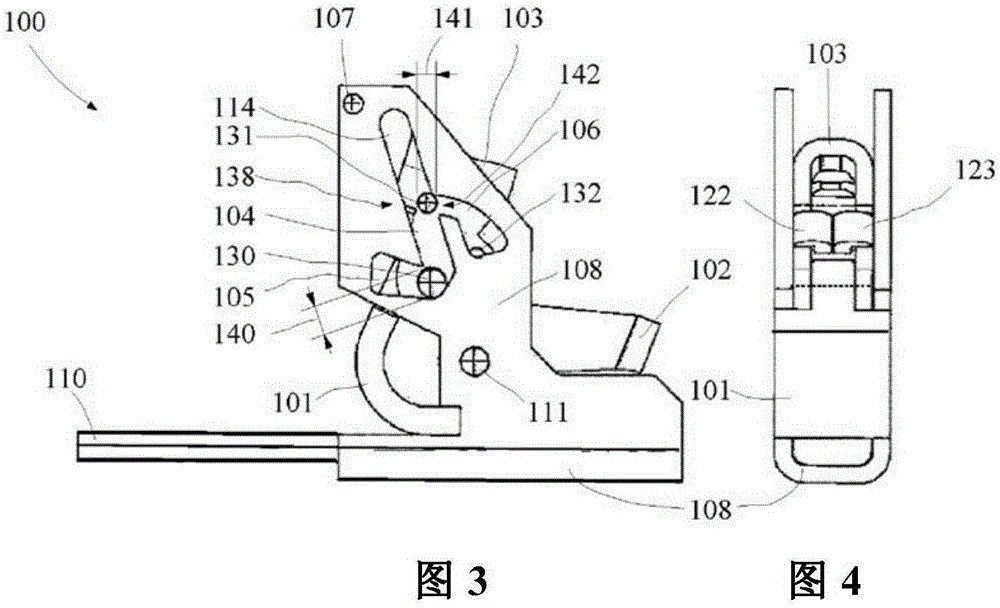

[0044] In the clamped state 145 ( Figure 10 ), the clamping rod 102 clamps the inserted conductor 106 towards the current bar 110 . The current bar 110 is accommodated on a support 108 which may be surrounded by a plastic casing not shown in the figures. The connection terminal 100 can be designed as a terminal block.

[0045] The clamping lever 102 is rotatably accommodated on the bracket 108 via a shaft 111 . The pin 136 of the clamping spring 101 rests on the shaft 111 (see Figure 7 ).

[0046] Joystick 103 has (see figure 2 ) tool opening 109. A first shaft 130 and a second shaft 131 are arranged on the joystick. Ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com