Height-adjustable medical bearing assembly

A high-level, component-based technology, applied in control/regulation systems, control using feedback, non-electric variable control, etc., can solve problems such as increased maintenance costs, shortened service life of equipment, and unexpected shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

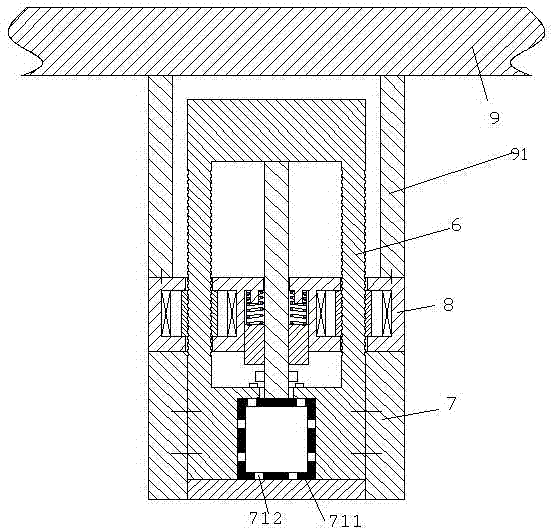

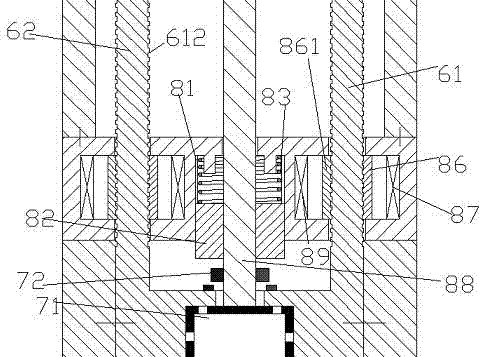

[0012] Combine below Figure 1-3 The present invention will be described in detail.

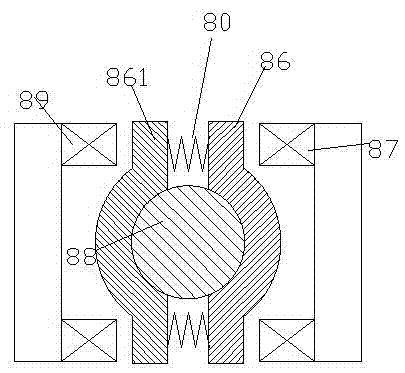

[0013] A height-adjustable medical bearing assembly according to an embodiment, comprising a base frame 7, a guide bearing column part 6 fixedly connected with the base frame 7, a movable bearing part 8, a platform part 9 and connecting the platform part 9 with the movable The connecting portion 91 fixedly connected to the dynamic bearing part 8; wherein, the platform part 9 is used to carry loads, and the guide bearing column part 6 includes two guide bearing columns 61, 62 arranged symmetrically, each of the guide bearing columns 61, 62 are provided with uniformly distributed annular teeth 612, and the movable load-bearing part 8 includes a pair of load-bearing clamps arranged bilaterally and symmetrically for respectively cooperating with the annular teeth 612 of the two guide bearing columns 61, 62. Each pair of bearing clips includes two toothed clips 86, 861 oppositely arranged, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com