Fully-automatic bucket bagging machine

A bagging machine, fully automatic technology, applied in the direction of external support, packaging, wrapping paper shrinkage, etc., can solve the problems of no saving of film materials, high cost of film materials, complex structure, etc., to save the use of film materials and ensure continuous Sexuality, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

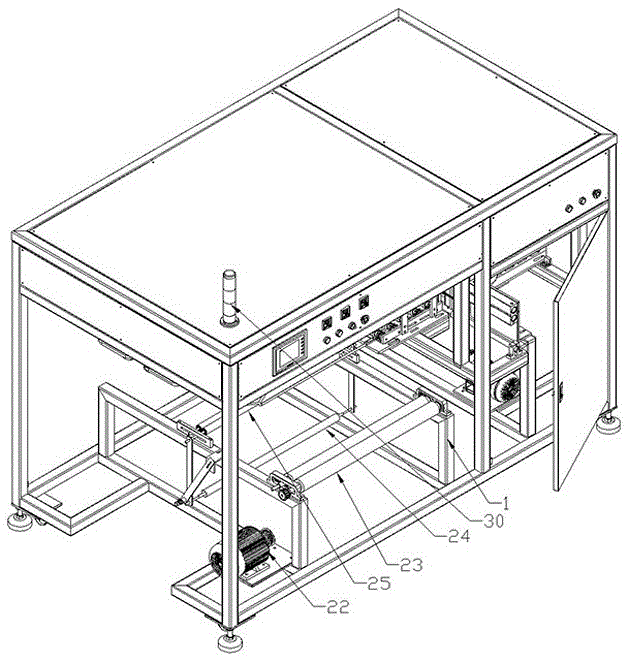

[0028] Such as figure 1 As shown, the present invention includes a frame 1, on which a bucket delivery mechanism, a film material delivery device, a bagging device and a bucket output device are arranged, and the bagging device is arranged on the bucket of the bucket delivery mechanism. At the output end, the film material delivery device separates the double-layer film material from one end and transports it to the bagging device. The bagging device bags the water bucket 32, and the water bucket output device packs the bagged water bucket 32 outputs to the rack 1 outside. The above-mentioned double-layer film material is formed by folding a long piece of film material from the middle position in the length direction, and then stacking it.

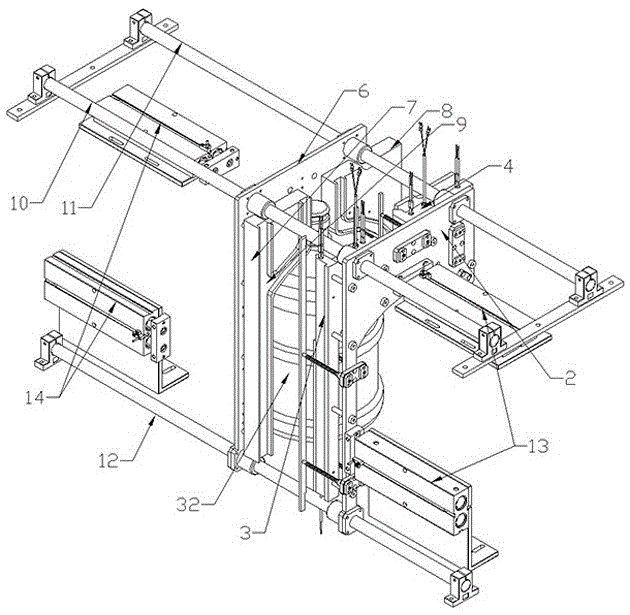

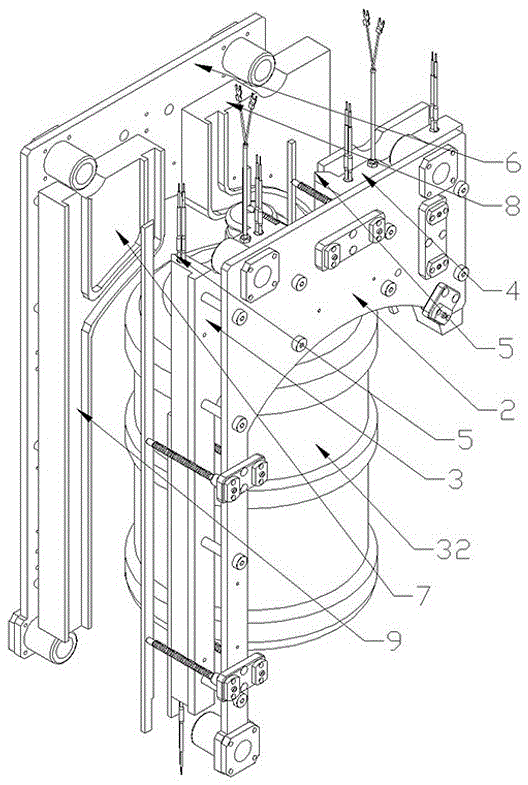

[0029] Such as Figure 2 to Figure 3 As shown, the bagging device includes a hot mold and a cold mold that are arranged in rows and left and right, and the hot mold includes a hot mold fixing plate 2, a first hot mold 3 and a second hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com