A separate automatic rebound horizontal shear locking device

A technology of horizontal shearing and locking devices, which is applied to building components, earthquake resistance, etc., can solve problems such as pipeline breakage and secondary damage, and achieve the effect of preventing vertical deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

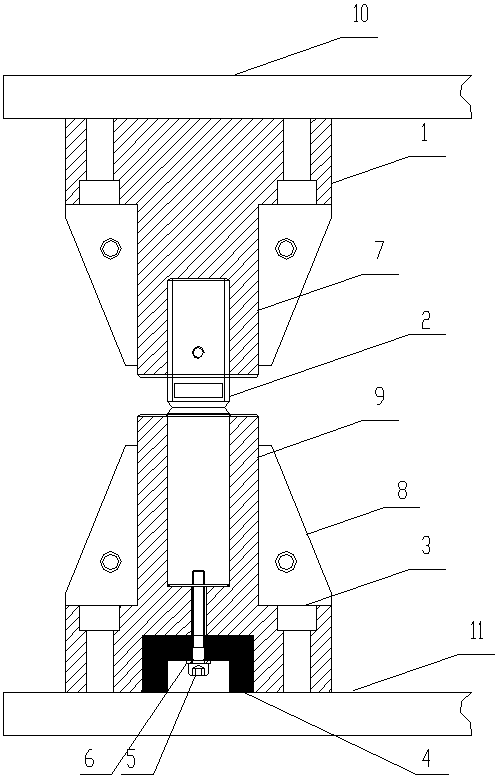

[0034] like figure 1 , Figure 3-Figure 16 As shown, a separate automatic rebound horizontal shear locking device is characterized in that it includes an upper flange 1, a shear pin 2, a lower flange 3, a rubber sleeve 4, a screw 5, a backing plate 6, and an upper sleeve 7. Reinforcing rib 8, lower sleeve 9, upper connecting plate 10, lower connecting plate 11; the upper flange 1, upper sleeve 7 and reinforcing rib 8 are welded together, and connected to the upper part through the upper connecting plate 10 The structure is fixed, the lower flange 3, the lower sleeve 9 and the reinforcing rib 8 are welded together and fixed to the foundation through the lower connecting plate 11; the bottom end of the upper sleeve 7 and the top end of the lower sleeve 9 A round hole is reserved in the center, and the two ends of the shear pin 2 are respectively inserted into the round holes of the upper sleeve 7 and the lower sleeve 9; the lower sleeve 9 and the rubber sleeve 4 are bonded thro...

Embodiment 2

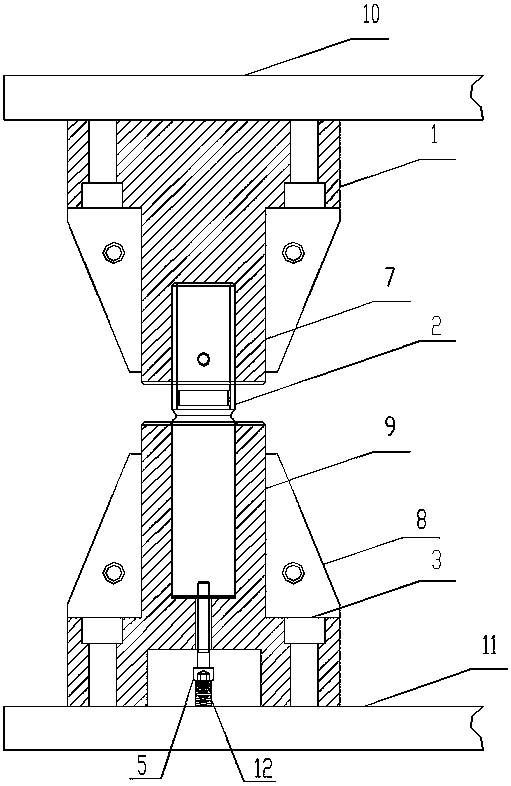

[0037] like Figure 2-Figure 12 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the rubber sleeve 4 and the backing plate 6 are replaced by a spring 12, and after the spring 12 is stretched, one end is connected to the screw 5, and the other end is connected to the lower connecting plate 11 , so that the spring 12 generates a pre-tension force after the screw 5 is tightened, so that the lower half of the shear pin 2 can rebound downward after being cut off, without affecting the normal hysteresis of the rubber bearing.

[0038] This horizontal shear lock is used in conjunction with rubber isolator mounts. The rubber shock-isolation bearing is fixed to the upper structure through the upper connecting plate 10, and fixed to the foundation through the lower connecting plate 11, and bears the vertical force of the upper structure. The upper connecting plate 10 and the lower connecting plate 11 produce a horizontal displacement under the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com