Horizontal shearing locking shock isolation device

A horizontal shearing and seismic isolation technology, applied in the direction of earthquake resistance, building components, etc., can solve problems such as pipeline fracture and secondary damage, and achieve the effect of preventing vertical deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

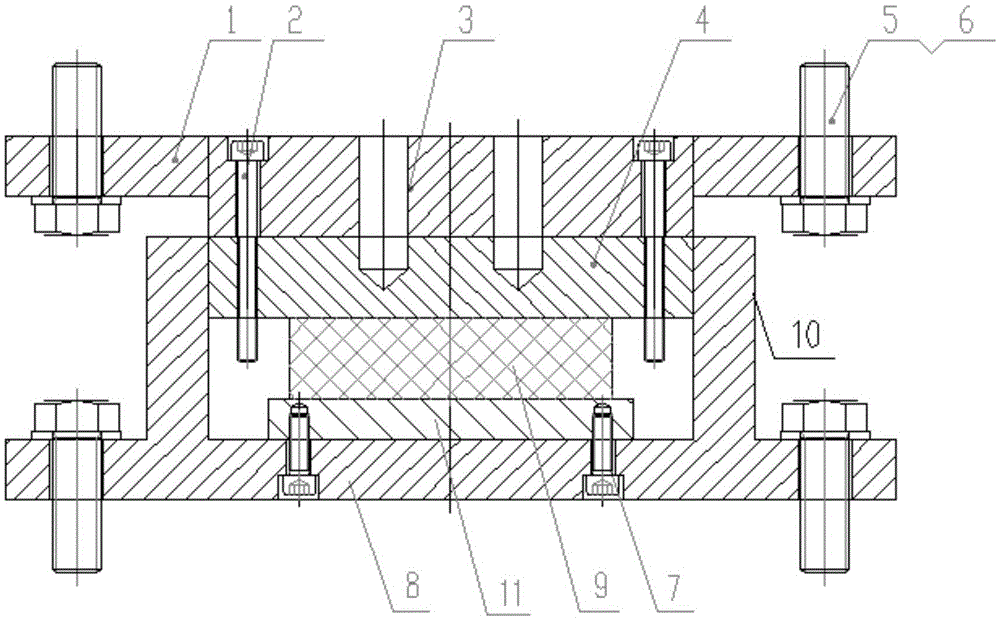

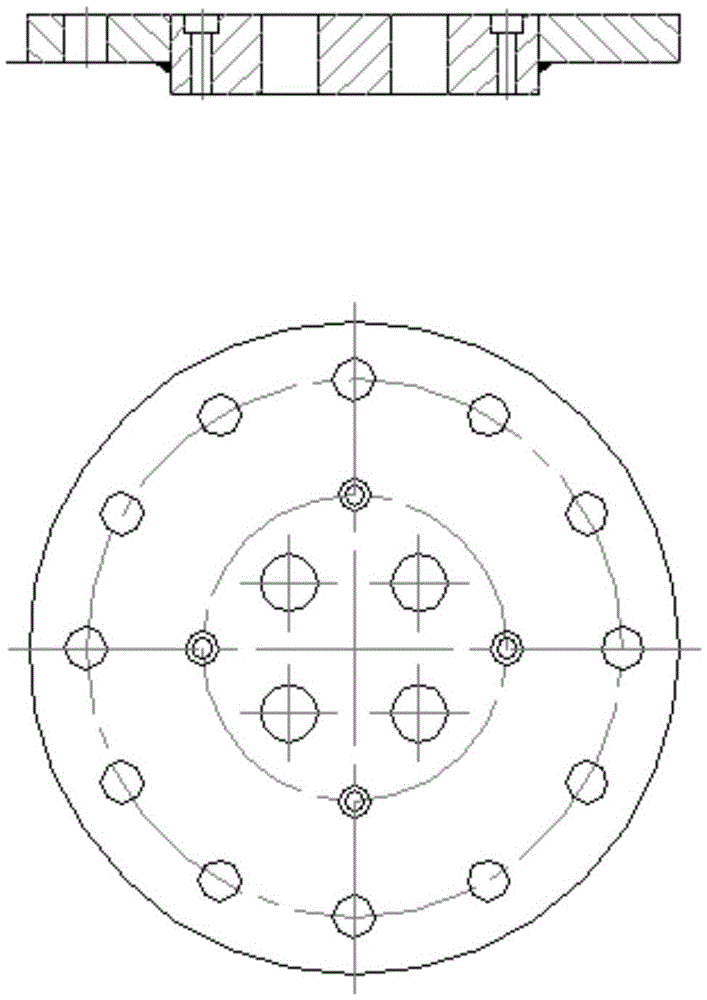

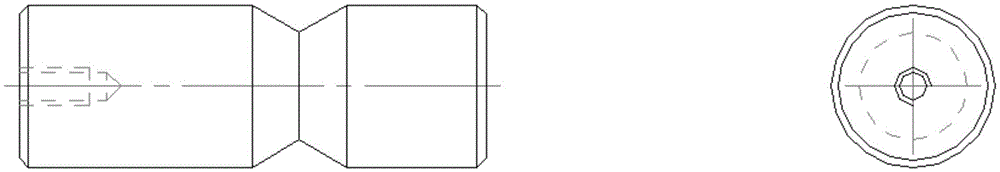

[0023] Such as Figure 1-Figure 7 As shown, a horizontal shear locking seismic isolation device, a horizontal shear locking seismic isolation device, is characterized in that it includes an upper body (1), hexagon socket head cap screws (2), shear pins (3), Intermediate body(4), hexagon head bolt(5), flat washer(6), hexagon socket head cap screw(7), lower body(8), rubber rod(9), sleeve(10), backing plate(11) ; The upper body (1) is fixed to the upper structure by hexagon head bolts (5), and the shear pin (3) passes through the upper body (1) and the middle body (4) to bear horizontal shear force, and the middle body ( 4) Connect with the rubber rod (9), apply a pre-tension force to the intermediate body (4) through the hexagon socket head cap screw (2) so that the rubber rod (9) is in a pre-tensioned state, and the sleeve (10) restricts the intermediate body (4) horizontal movement. The locking device bonds the backing plate (11) with the intermediate body (4) and the rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com