An Anti-Pull Shear Locking Device

A locking device and anti-pulling technology, which can be used in building components, shockproof and other directions, can solve problems such as pipeline fracture and secondary damage, and achieve the effect of preventing vertical deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

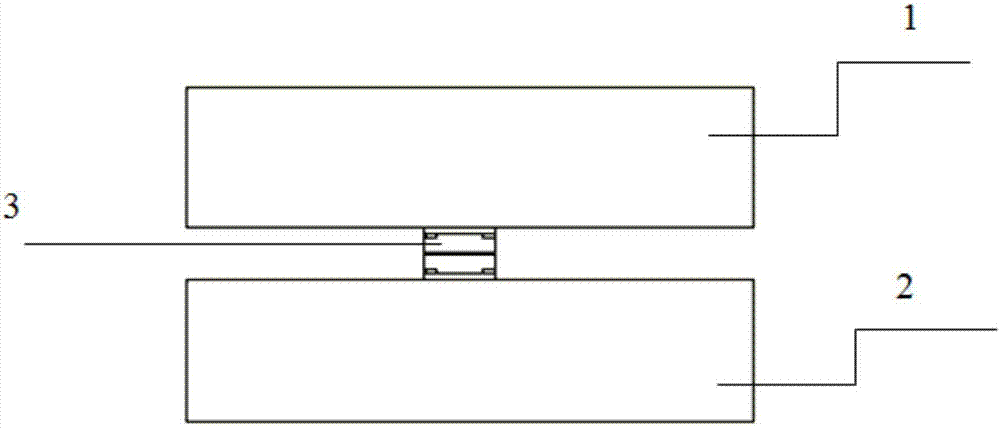

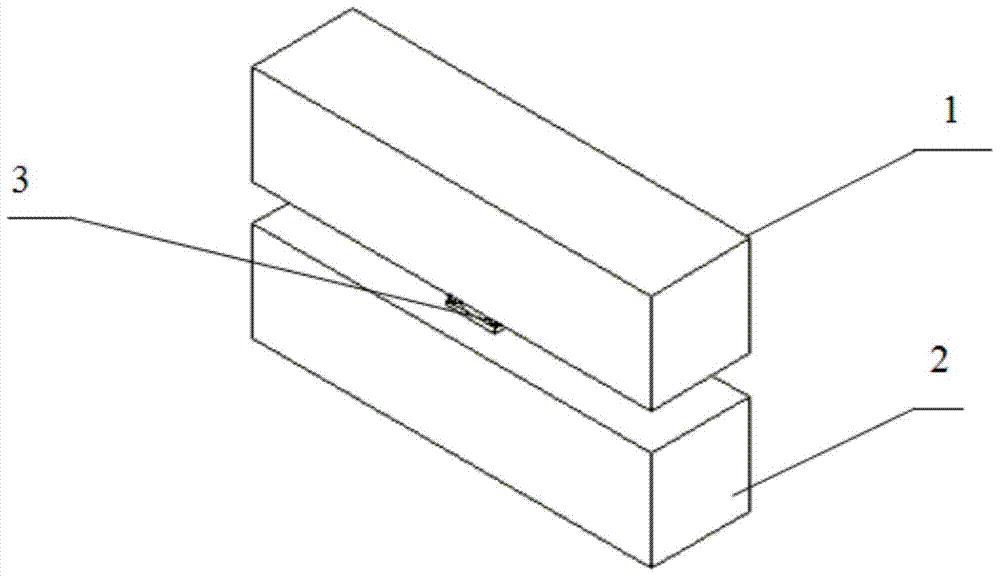

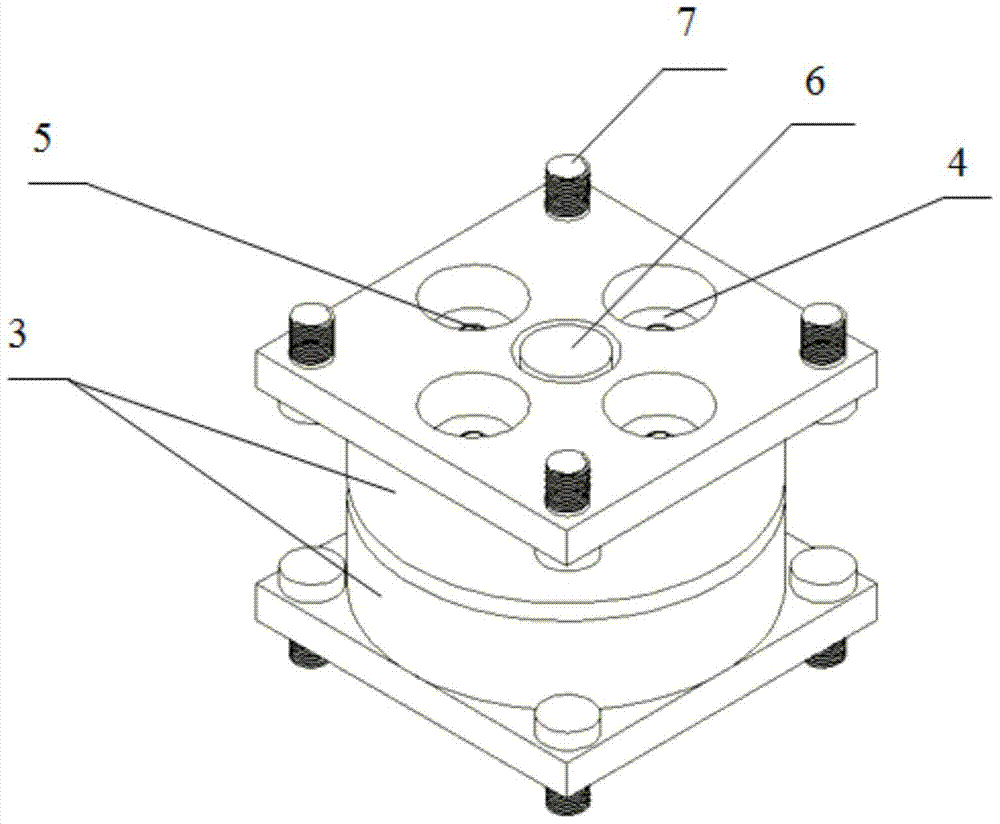

[0034] Such as Figure 1-Figure 10 As shown, the anti-drawing shear locking device described in this embodiment includes an upper beam 1, a lower beam 2, a square-bottomed cylindrical steel member 3, a tapered sleeve 4, a double-ended screw 5, a cylindrical ceramic 6, and high-strength bolts 7. The square bottom plate of the square-bottomed cylindrical steel member 3 is provided with a threaded hole 8, and the cylindrical body is provided with a round hole 9 and a tapered hole 10; the square-bottomed cylindrical steel member 3 is connected with the bolt 7 through the reserved hole 8 The upper and lower beams 1, 2; the tapered sleeve 4 is set in the reserved hole 10 of the square-bottomed cylindrical steel member 3, the outer diameter of the upper cylinder of the tapered sleeve 4 is the same as the inner diameter of the reserved hole in the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com