Optical fiber preform transverse transmission clamping device capable of transverse transmission

An optical fiber preform and clamping device technology, which is applied in the directions of transportation and packaging, conveyors, manufacturing tools, etc., can solve the problems of inconvenient manual operation and low efficiency, and achieve the effect of convenient clamping and transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

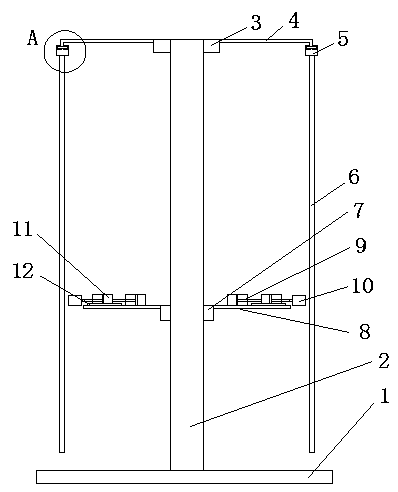

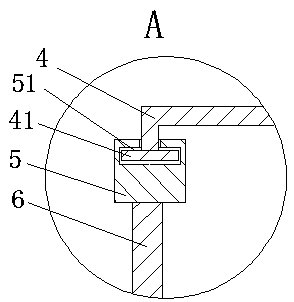

[0016] The optical fiber preform transverse transport clamping device for transverse transport of the present invention comprises a base, a suspension device and a transverse transport clamping device. The base includes a base 1 placed on the ground, and a vertical rod 2 connected with the base 1 and arranged vertically. The suspension device includes a connecting ring 3 fastened on the upper end of the vertical bar 2 away from the base 1, a plurality of connecting posts 4 arranged on the connecting ring 3 and radially distributed along the vertical bar 2, and a connecting head 5 arranged on the connecting post 4, The upper end of the vertically arranged optical fiber preform rod 6 is connected to the connection head 5 . The transverse transmission clamping device includes a clamping ring 7 arranged on the vertical bar 2, a number of clamping columns 8 arranged on the clamping ring 7 and radially distributed along the vertical bar 2, and a driving device 9 arranged on the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com