Automobile rearview mirror of optimized structure

A car rearview mirror and lens technology, which is applied in the field of car rearview mirrors, can solve problems such as potential safety hazards, affecting the use of rearview mirrors, and inconvenient cleaning of rearview mirrors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

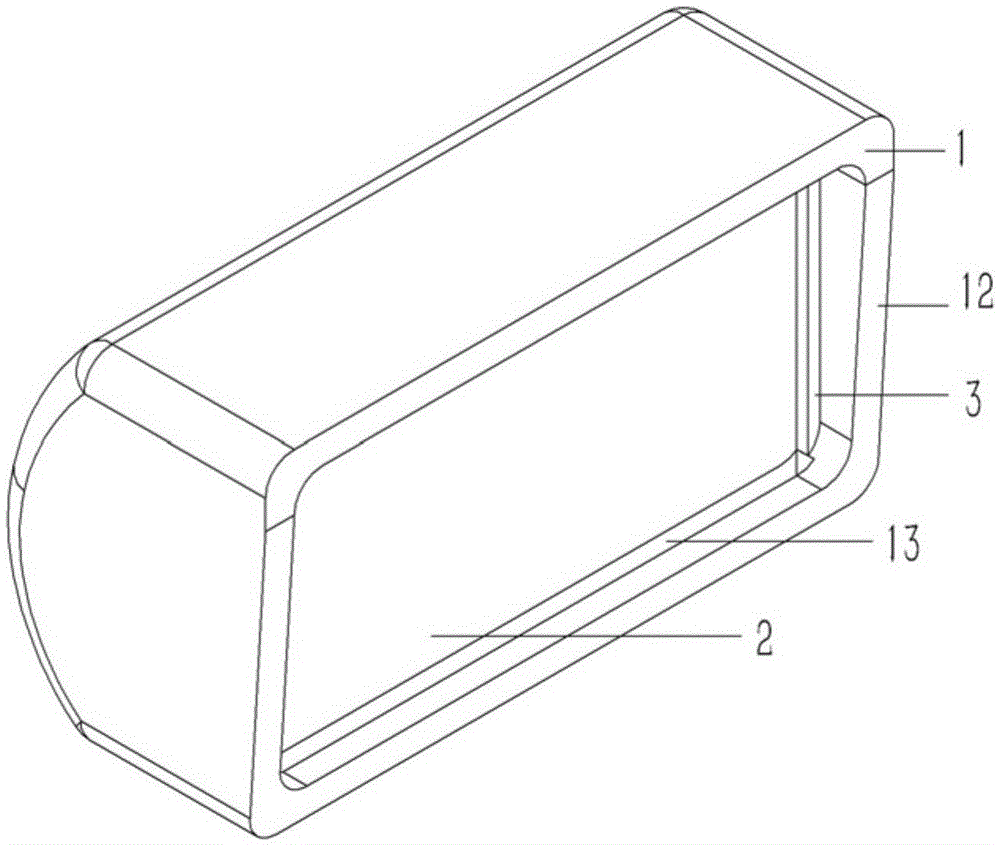

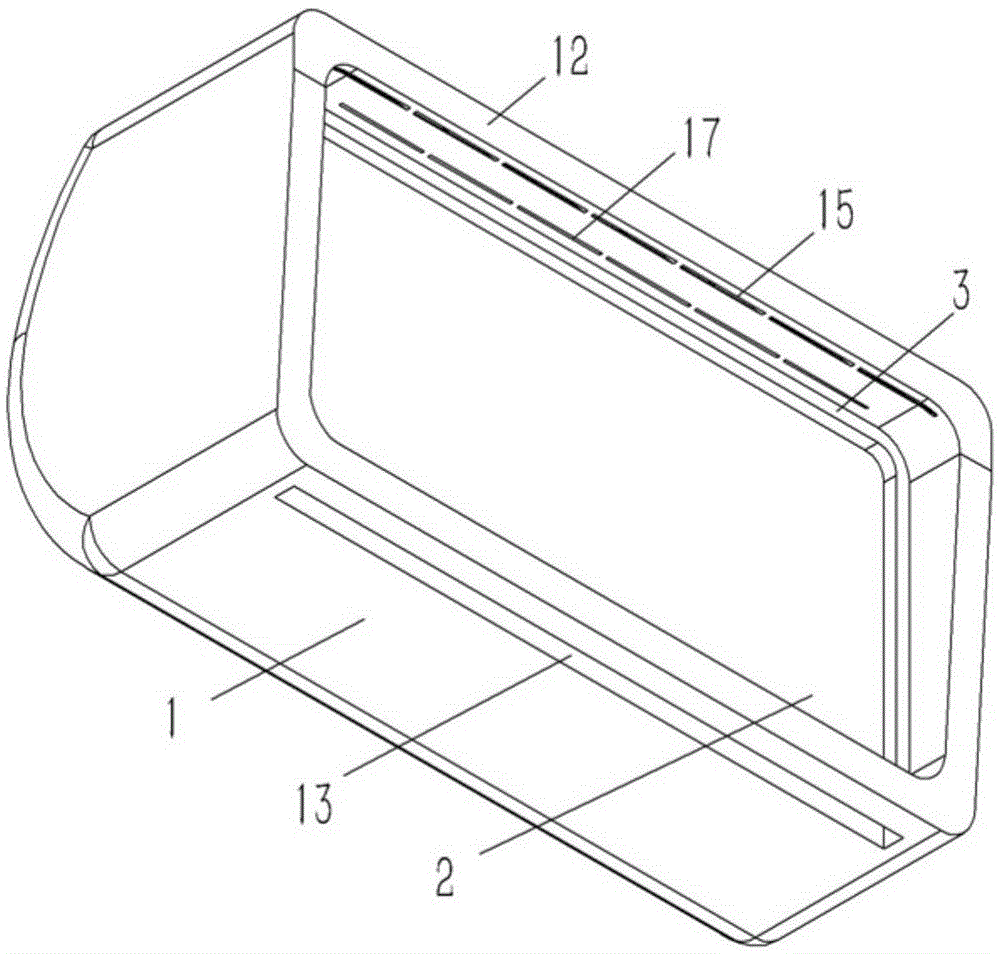

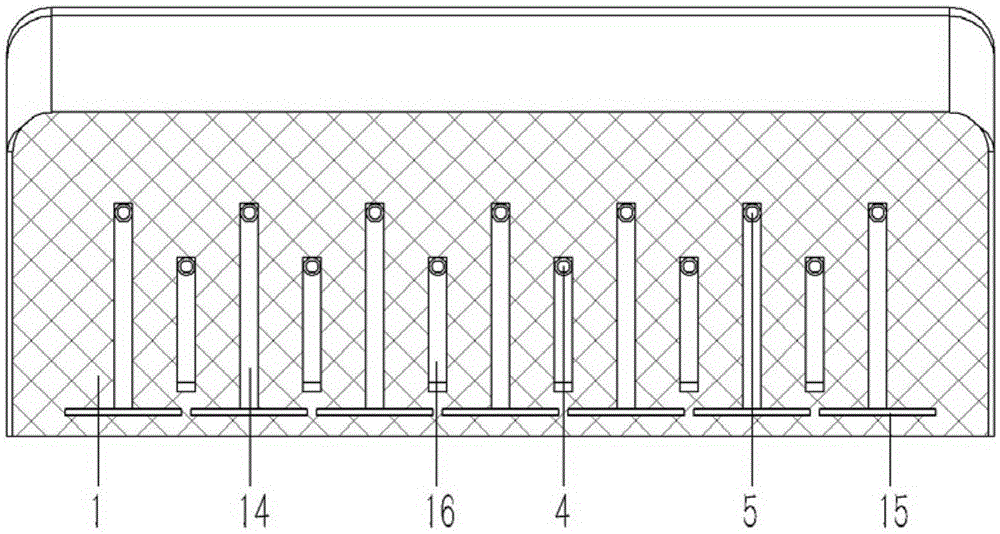

[0017] Example: see Figures 1 to 6 As shown, a structure-optimized automobile rearview mirror includes a housing 1 and a lens 2 of the automobile rearview mirror, an annular boss 11 is formed on the inner wall of the housing 1, and the lens 2 is fixed on the front end surface of the boss 11 On the front end surface of the lens 2, there is a "冂"-shaped bar 3, and the bar 3 is fixed on the inner wall of the housing 1, and the front end surface of the housing 1 around the lens 2 is formed with a frame extending forward. 12. A strip-shaped water leakage groove 13 is formed on the bottom surface of the frame body 12 on the front side of the boss 11; a number of air curtain air channels 14 and water blowing air channels 16 are formed in the frame body 12 above the lens 2 and the housing 1, The air curtain air channel 14 and the water blowing air channel 16 are evenly distributed in the frame body 12 and the housing 1 in a staggered manner;

[0018] The frame body 12 is formed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com