Special pile inverting frame for trolley

A technology of inverted piles and trolleys, which is applied to earth movers/excavators, construction, etc., can solve the problems of inability to guarantee the safety of workers, high requirements for hole positioning accuracy, and cumbersome operations, so as to save manpower and improve work efficiency , high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

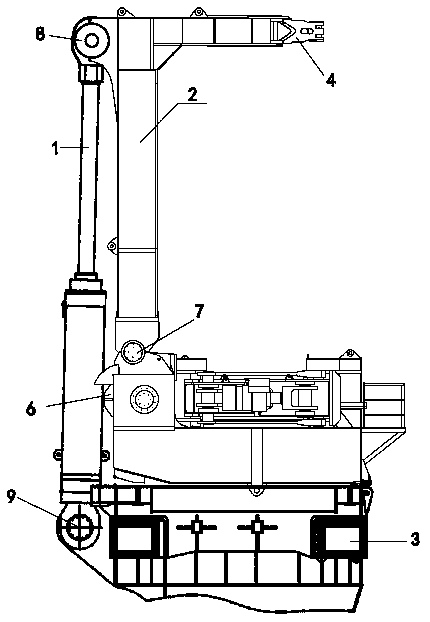

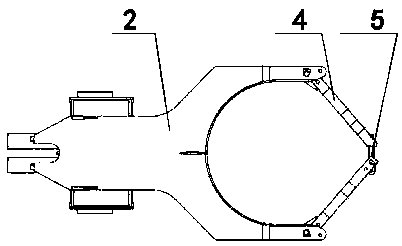

[0014] The utility model relates to an inverted pile frame specially for a trolley, comprising a base 3, an inverted pile arm 2, a group of pile holding arms, a locking device 5, a first hinge point 7, and an inverted pile retracting and pushing device. A set of pile-holding arms includes 2 pile-holding arms 4 . The locking device 5 is a bolt.

[0015] The pile-reeling pushing device includes a pile-reversing oil cylinder 1 , a second hinge point 9 and a third hinge point 8 .

[0016] The base 3 includes an anti-collision device 6 .

[0017] The cross section of the pile-reversing arm 2 in a certain direction is in an "L" shape, and the bottom end of the pile-reversing arm 2 is movably connected to the base 3 through a first hinge point 7 . The cross-section of the other top end of the pile-reversing arm 2 in a certain direction is arc-shaped. A group of pile-holding arms is connected with the arc-shaped top end of the pile-reeling arm 2 , that is, one end of the two pile-h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com