Heat exchangers and air conditioning units

A technology of heat exchangers and heat exchange parts, which is applied in the direction of heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve problems such as bias currents, and achieve the effect of suppressing bias currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] (1) Overall structure of the air conditioner 1

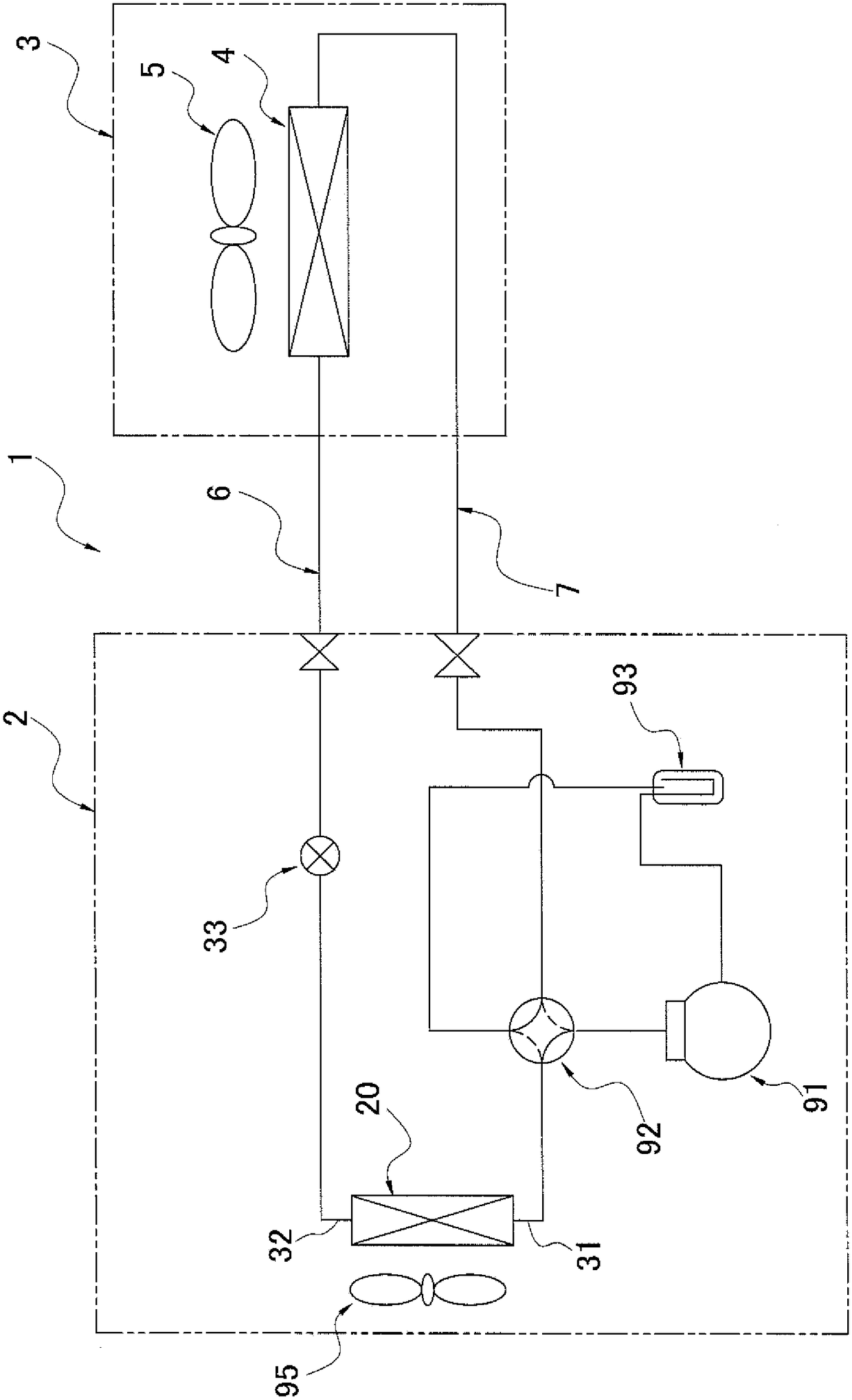

[0056] figure 1 It is a circuit diagram showing the outline of the configuration of the air conditioner 1 according to one embodiment of the present invention.

[0057] The air conditioner 1 is a device used for cooling and heating in a building in which an air conditioner indoor unit 3 is installed by performing a vapor compression refrigeration cycle operation. The indoor units 3 are connected by refrigerant communication pipes 6 and 7 .

[0058] The refrigerant circuit formed by connecting the air-conditioning outdoor unit 2, the air-conditioning indoor unit 3, and the refrigerant communication pipes 6 and 7 is to connect the compressor 91, the four-way switching valve 92, the outdoor heat exchanger 20, and the expansion valve through refrigerant piping. 33. The indoor heat exchanger 4 and the storage tank 93 are connected to form. A refrigerant is sealed in this refrigerant circuit, and a refrigeration cycle operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com