Double oil shaking taro harvester

A harvester and taro technology, applied in the field of agricultural and forestry machinery, can solve the problems of difficulty in obtaining mechanized harvesting quality and unsatisfactory effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

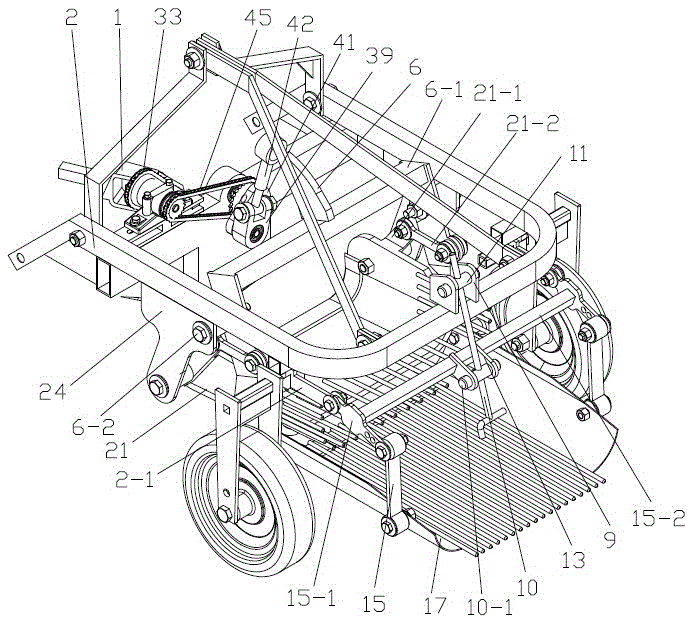

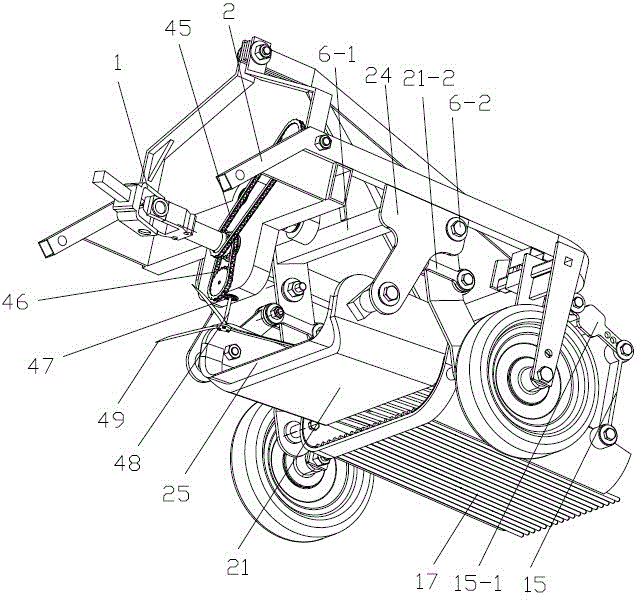

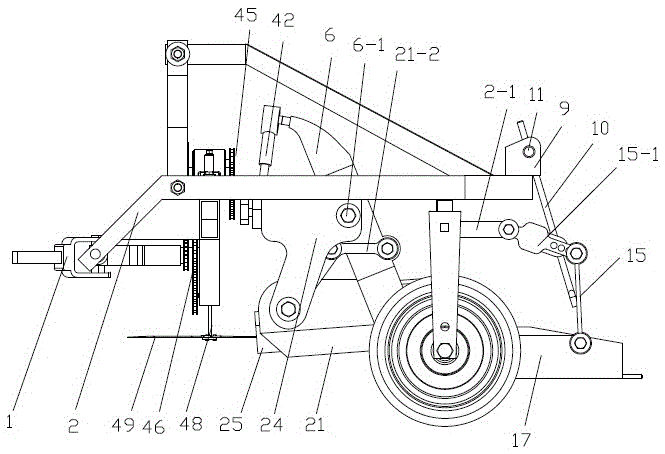

[0016] The taro double shaking soil harvester of the present embodiment is as Figures 1 to 4 As shown, the frame 2 is supported on the ground wheels, and is mainly composed of a horizontal U-shaped frame and an approximate large-character support frame fixed on the upper part. The earth scraper 25 is installed below the front part of the frame 2, and the soil shaking mechanism is installed after the earth scraper 25. The soil shaking mechanism contains a front soil shaking shovel 21 and a rear soil shaking shovel 17 connected to each other.

[0017] The bottom of the front end of the front soil shaking shovel 21 is hinged on the lower end of the T-shaped connecting plate 24 fixed on the frame, and the upper end of the swing arm 21-1 extending upward on both sides of the front end is hinged with the front end of the short connecting rod 21-2. The rear end of the short connecting rod 21-2 is hinged with the middle part of the door-shaped swing link 6-1 of the main swing frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com