Method and system for detecting the inclination of a detection disc of a motor rotor

A detection method and detection system technology, which can be applied in directions such as measuring inclination, measuring device, surveying and mapping, and navigation, etc., and can solve problems such as large detection error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

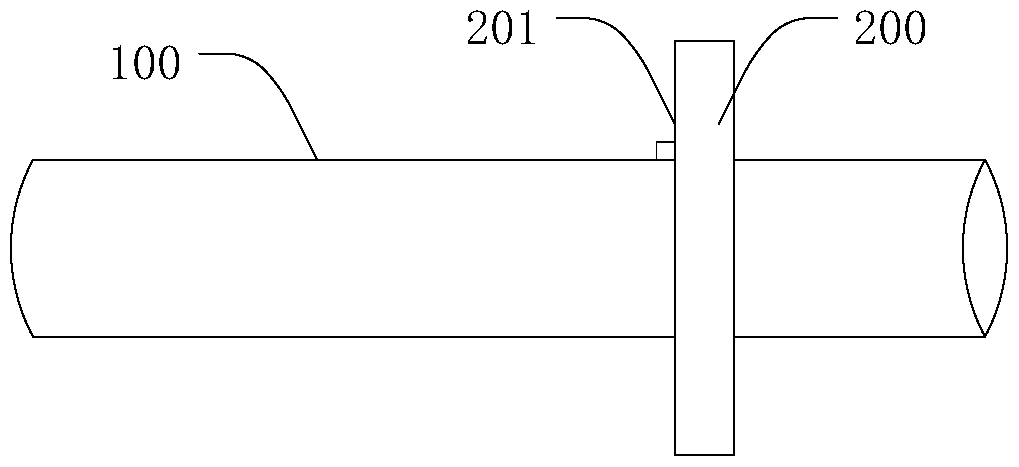

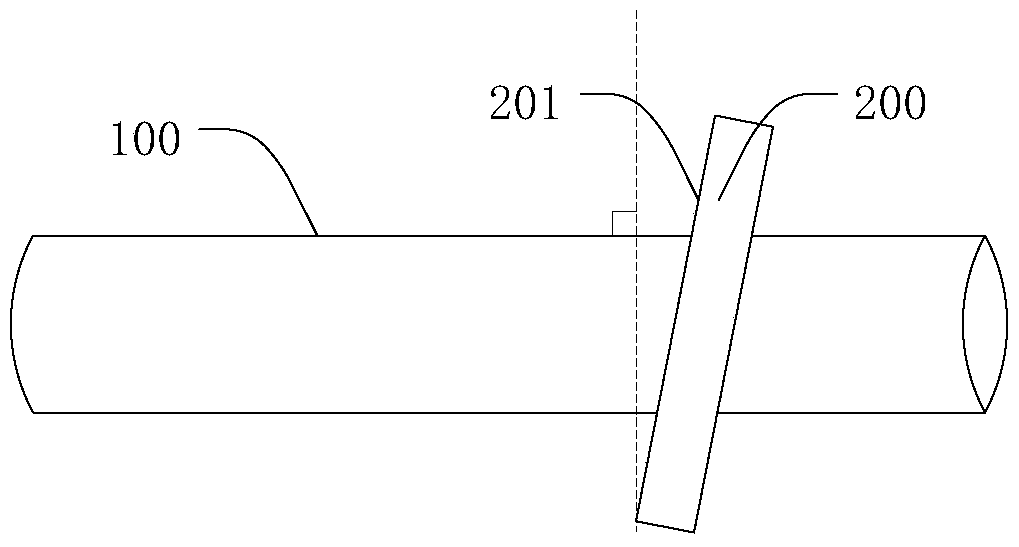

Image

Examples

Embodiment 1

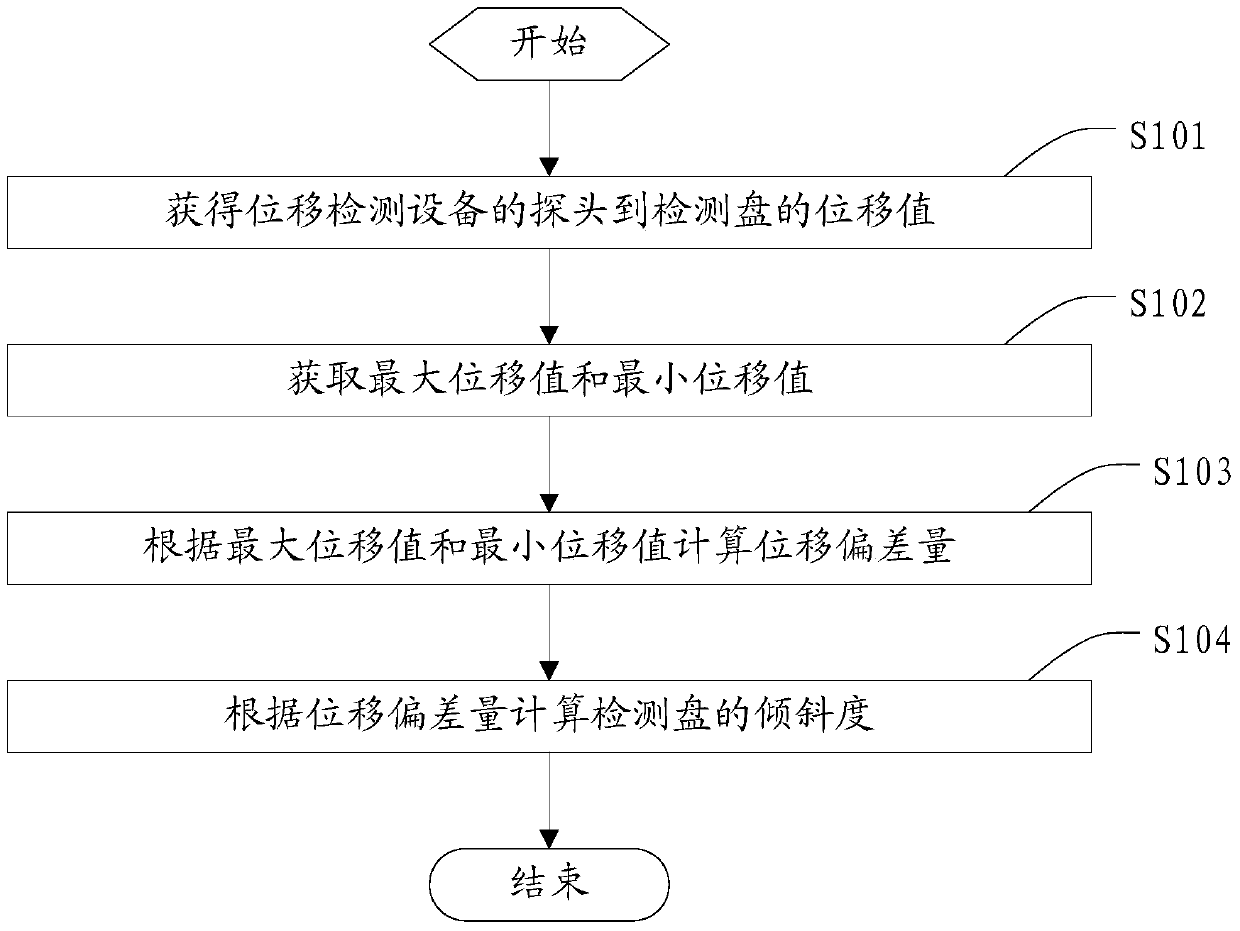

[0045] image 3 This is a flow chart of steps of a method for detecting the inclination of a detection disk of a motor rotor provided in an embodiment of the present application.

[0046] like image 3 As shown, the method for detecting the inclination of the detection disc of the motor rotor provided in this embodiment is applied to a magnetic suspension bearing system, which is used to detect the inclination of the detection disc on the rotating shaft of the motor in the system, and judge the inclination of the detection disc by detecting the inclination. Whether the assembly is qualified. Specifically include the following steps.

[0047] S101: Obtain the displacement value from the probe of the displacement detection device to the detection disk.

[0048] The distance between the probe of the displacement detection device and the detection disc is detected by a displacement detection device disposed opposite to the detection disc, and a plurality of displacement values ...

Embodiment 2

[0058] Figure 5 A flow chart of steps of a method for detecting the inclination of a detection disk of a motor rotor provided by another embodiment of the present application.

[0059] like Figure 5 As shown, the method for detecting the inclination of the detection disc of the motor rotor provided in this embodiment is applied to a magnetic suspension bearing system, which is used to detect the inclination of the detection disc on the rotating shaft of the motor in the system, and judge the inclination of the detection disc by detecting the inclination. Whether the assembly is qualified. Specifically include the following steps.

[0060] S201: Obtain the displacement value from the probe of the displacement detection device to the detection disk.

[0061] The distance between the probe of the displacement detection device and the detection disc is detected by a displacement detection device disposed opposite to the detection disc, and a plurality of displacement values ...

Embodiment 3

[0073] Image 6 Another embodiment of the present application provides a structural block diagram of a system for detecting the inclination of a detection disc of a motor rotor.

[0074] like Image 6 As shown, the detection system for the detection disc inclination of the motor rotor provided in this embodiment is applied to the magnetic suspension bearing system, which is used to detect the inclination of the detection disc on the rotating shaft of the motor in the system, and judge the detection disc by detecting the inclination. Whether the assembly is qualified. Specifically, it includes a displacement detection device 10 and a processing device 20 . The processing device 20 includes a data acquisition module 21 , a data judgment module 22 , a first calculation module 23 and a second calculation module 24 .

[0075] The displacement detection device 10 is disposed opposite to the detection surface of the detection disc, and is used to measure the distance between the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com