A coal preparation equipment anti-running coal system and coal preparation equipment

A kind of equipment and coal preparation technology, applied in the direction of swirling device, etc., can solve the problem of coal running out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

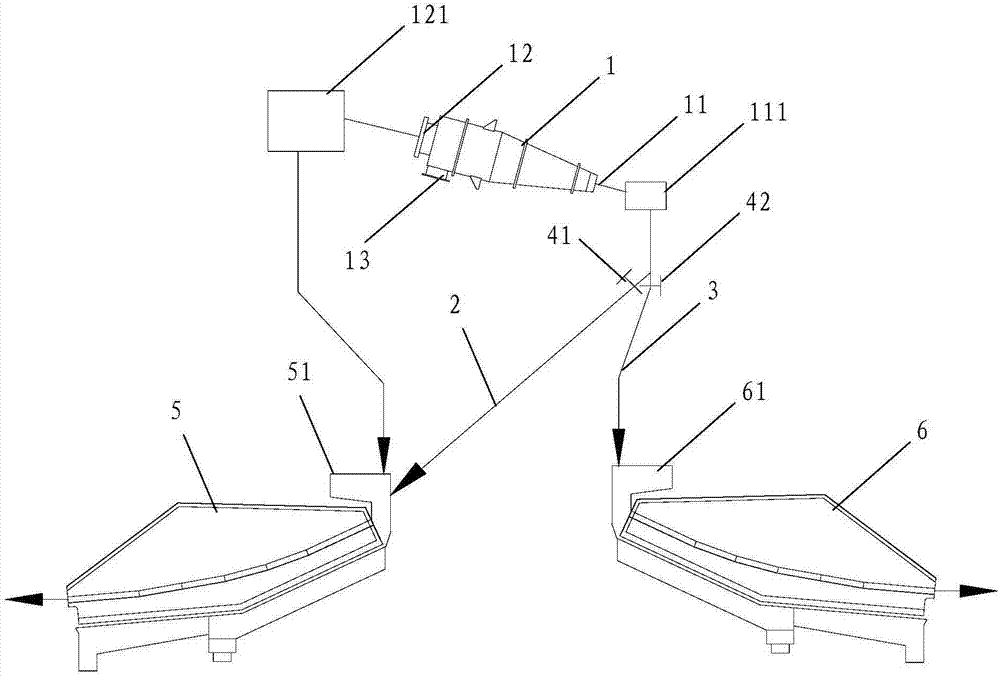

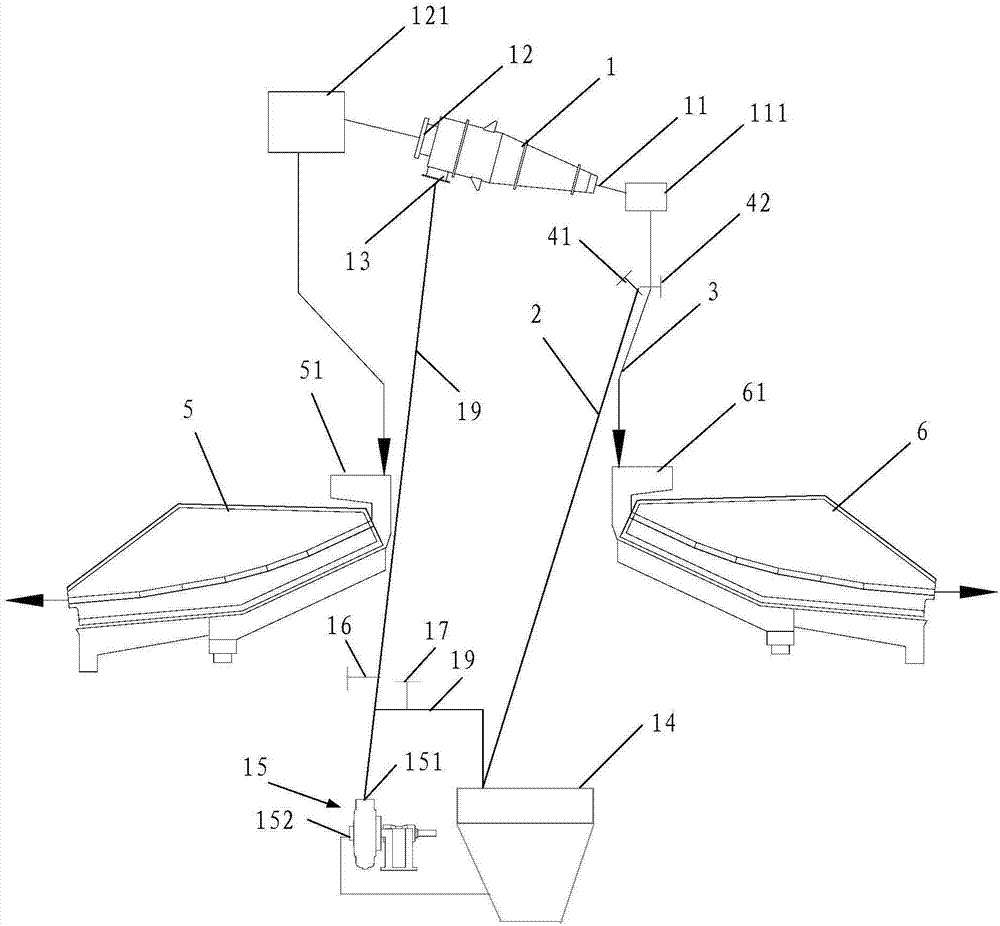

[0032] Such as figure 1 Shown is a structural schematic diagram of a coal preparation equipment of the present invention to prevent coal run-off system, the coal preparation equipment includes a pressurized two-product heavy medium cyclone 1, the underflow of the pressurized two-product heavy medium cyclone 1 Nozzle 11 communicates with underflow pipe 3, and the coal running prevention system includes: a detection unit, branch pipe 2, and control valve 4, and the underflow nozzle 11 is respectively connected to the input end of the branch pipe 2 and the The underflow pipe 3 is connected or disconnected;

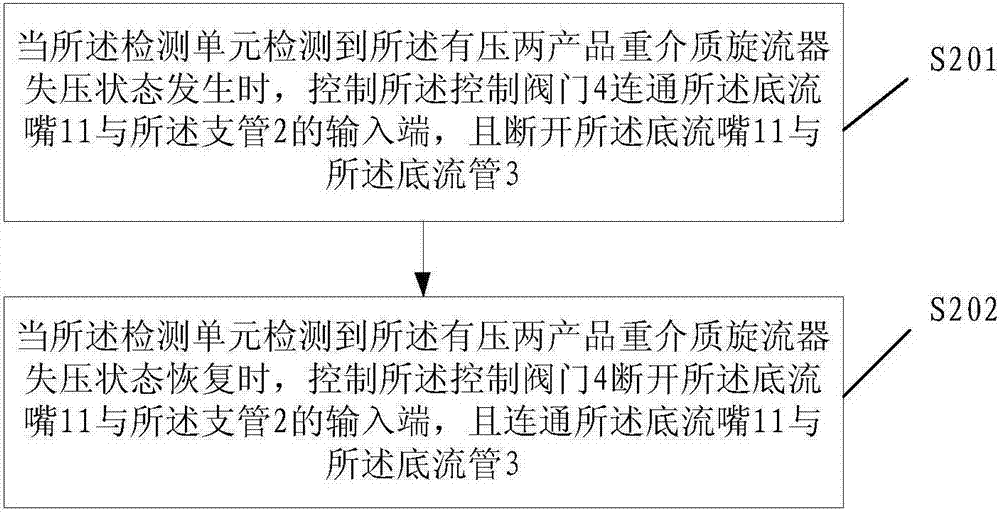

[0033] Such as figure 2 As shown, the detection steps are:

[0034] Step S201, when the detection unit detects that the pressurized two-product dense medium cyclone is under pressure, control the control valve 4 to communicate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com