A cable joint structure

A technology of cable joints and cables, which is applied in the direction of cable joints, conductive connections, circuits, etc., can solve the problems of large area occupied by cable branch boxes, large amount of operation and maintenance, etc., to solve the problem of large occupied area, ensure effective connection, avoid The effect of contact heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

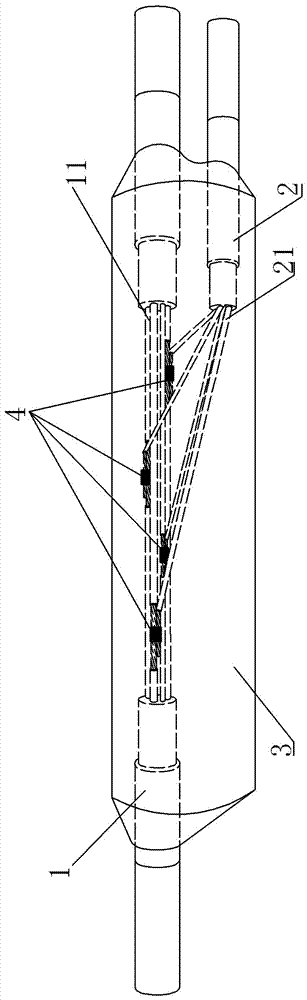

[0012] Such as figure 1 As shown, an embodiment of a cable joint structure, the joint structure in this embodiment includes two cables respectively having wiring sections, these two cables are a main circuit cable 1 and a branch circuit cable 2, wherein, The connection section 11 of the main circuit cable 1 is arranged in the middle of the main circuit cable 1, the connection section 21 of the branch circuit cable 2 is arranged at one end of the branch circuit cable 2, and the connection sections of the main circuit cable 1 and the branch circuit cable 2 have respectively The sequence corresponds to the exposed conductors of the conductive connection. The exposed conductors of each phase on the main circuit cable 1 and the exposed conductors of each phase on the branch circuit cable 2 are assembled together by crimping fittings 4. The exposed conductors of the main circuit cable 1 A solid insulating sheath 3 that completely wraps the above-mentioned conductive connection is po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com