General self-locking insulation protective cover cooperated with fast connecting terminal

A technology of insulation protection and insulation sleeve, applied in the direction of connection insulation, etc., can solve the problems of terminal loss of insulation protection, slow threading speed, narrow size, etc., and achieve the effect of speeding up wiring and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail by the following examples.

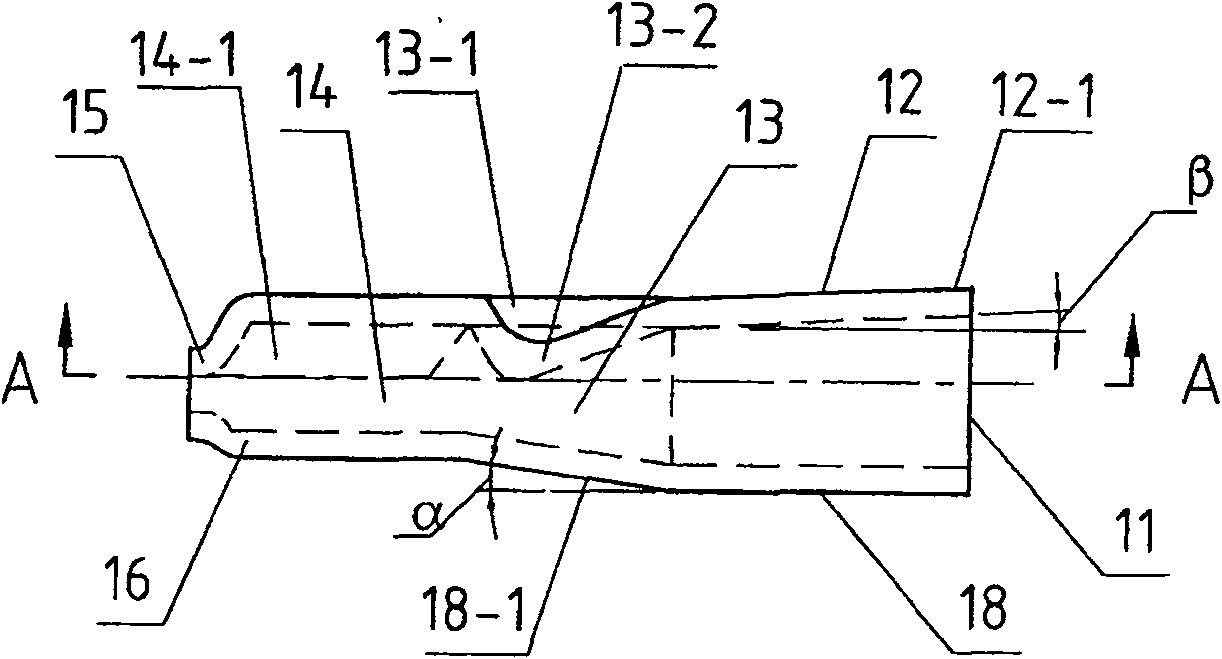

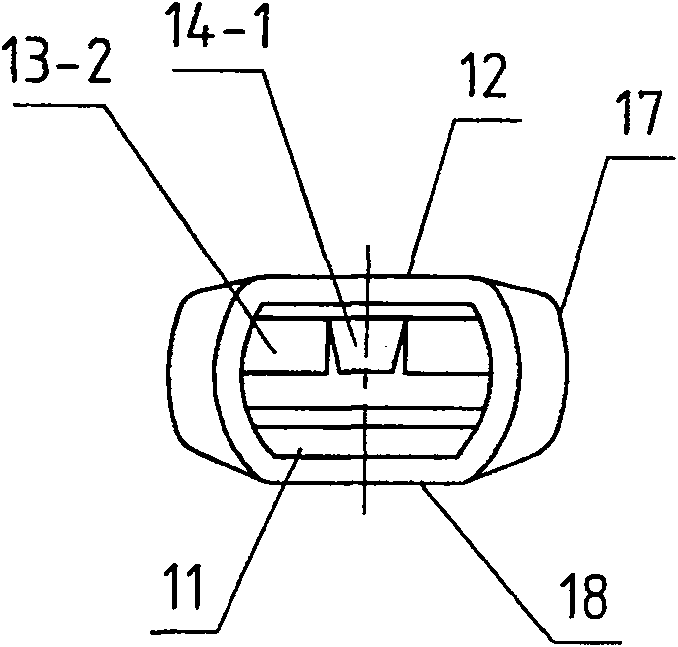

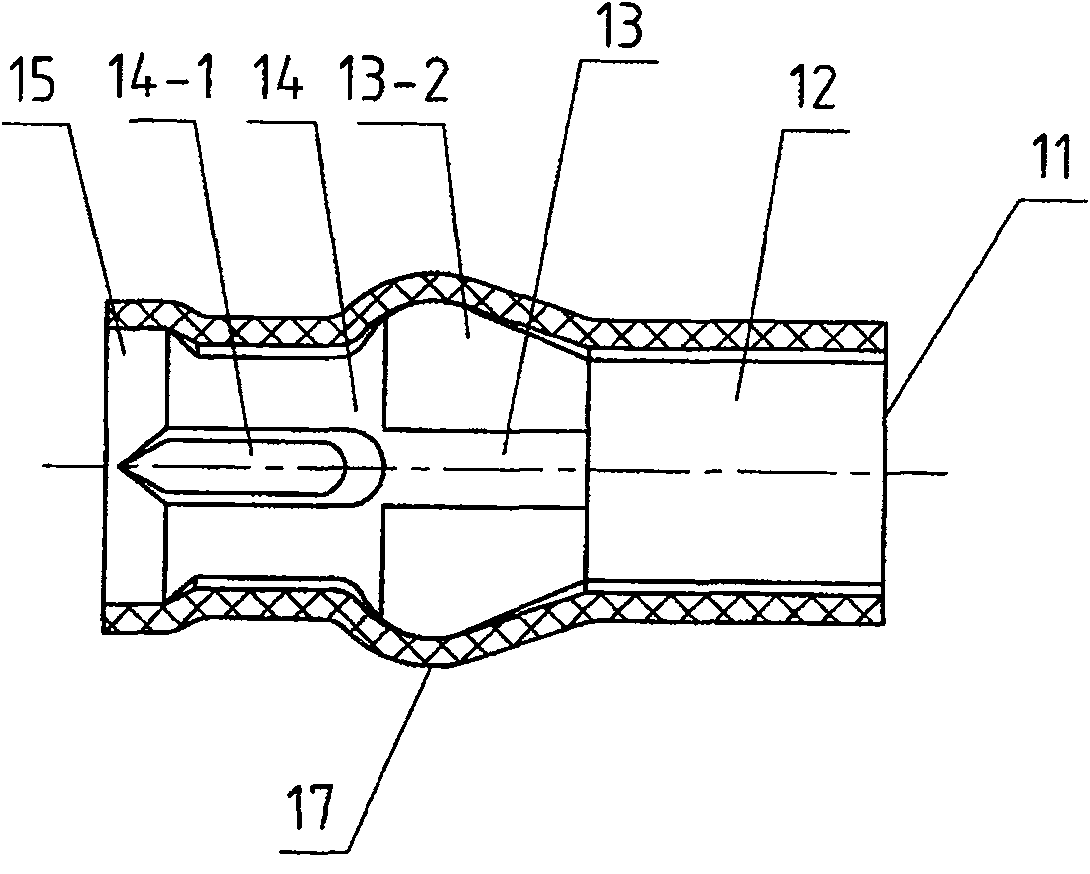

[0016] see figure 1 , figure 2 , image 3 and Figure 4 As shown, a universal self-locking insulating protective cover matched with a quick-connect terminal is composed of an insulating cover body 16 and its inner cavity, and the two ends of the insulating cover body 16 are respectively provided with a terminal inlet 11 and an insert piece inlet 15. The middle part of the sleeve body 16 is the terminal clamping portion 13, and the face 12 of the terminal clamping portion 13 is provided with a V-shaped terminal clamping groove 13-1 on both sides of the longitudinal direction of the insulating sleeve 16, correspondingly in the terminal clamping portion. The inner wall of the face of 13 is respectively formed with terminal locking bosses 13-2 along the two sides of the longitudinal direction of the insulating sleeve body 16. The section between the terminal locking groove 13-1 and the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com