Noise source separation method of uniform speed noise

A separation method and noise source technology, applied in the measurement of ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problem of inability to obtain ratios, inability to rectify and optimize interior noise, inability to obtain powertrain noise, Tire noise contribution and other issues to achieve the effect of improving performance and comfort and reducing vehicle noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

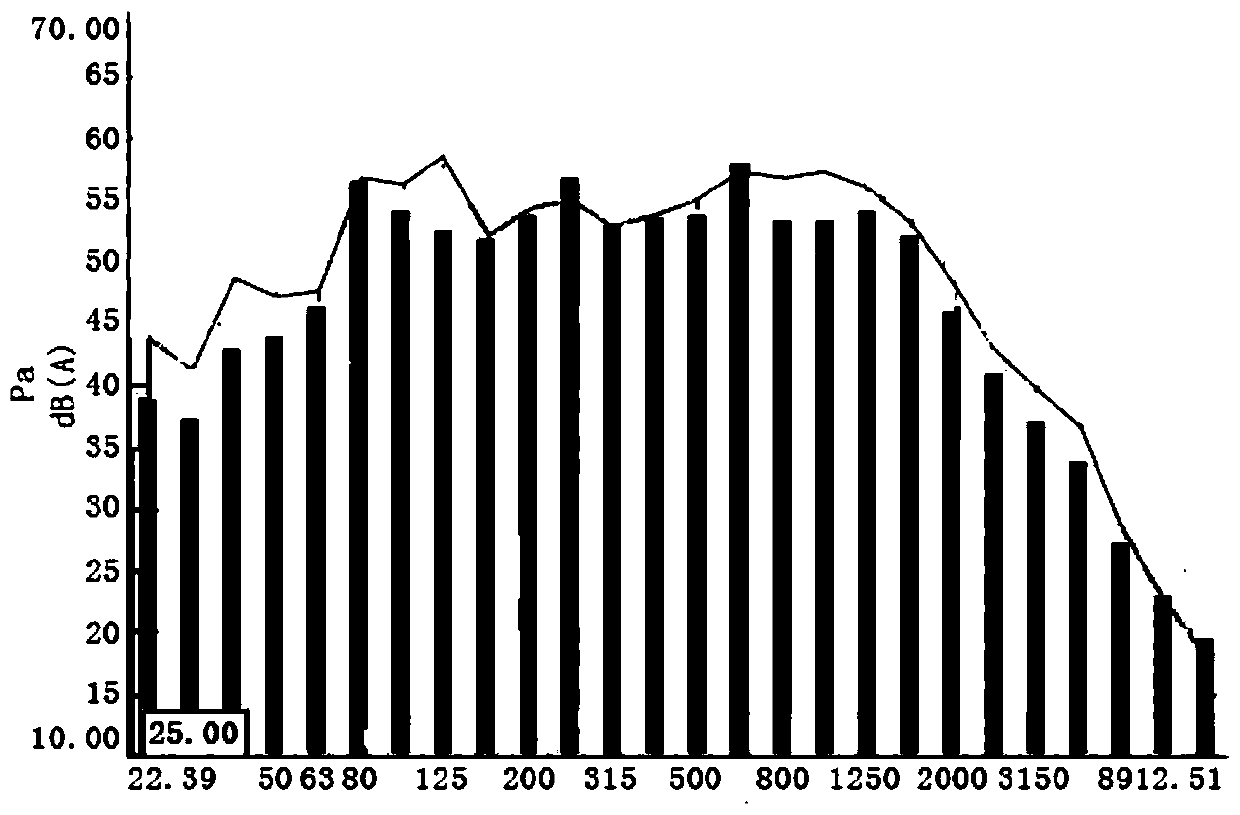

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

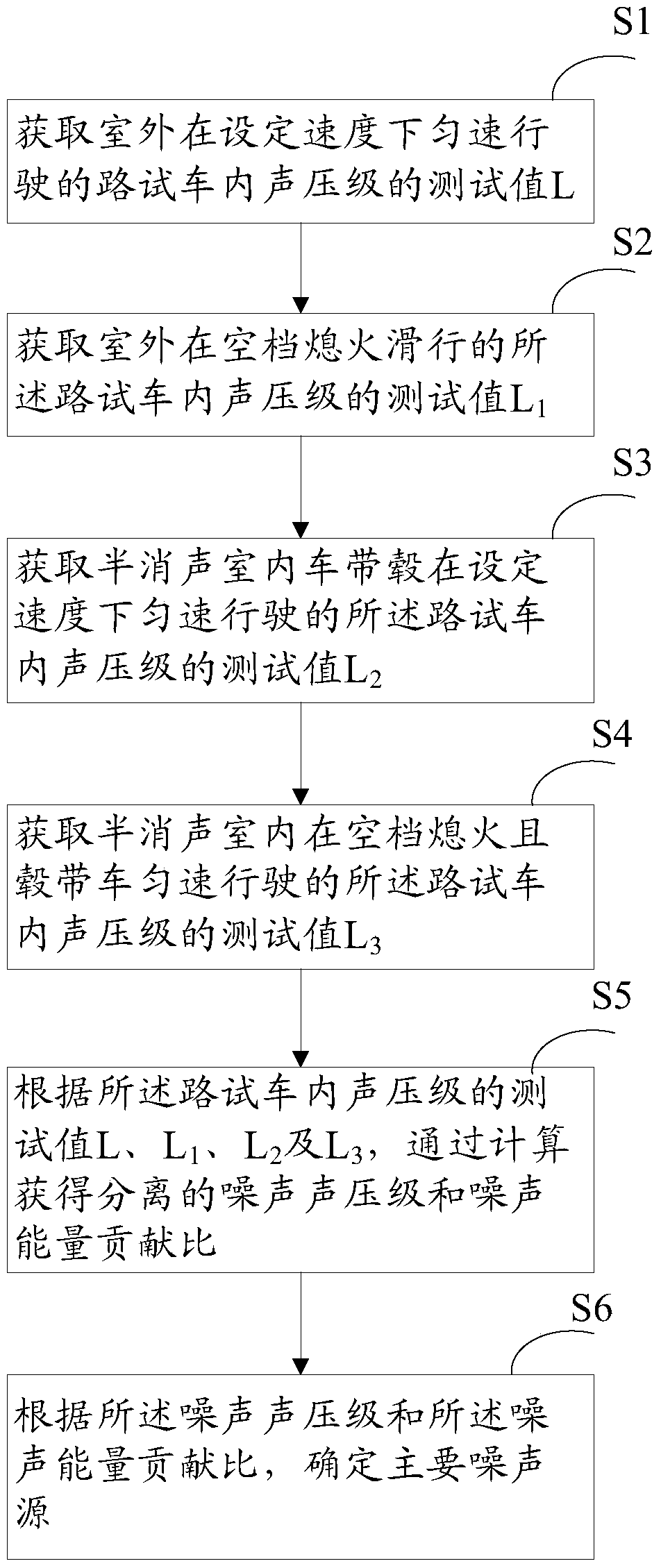

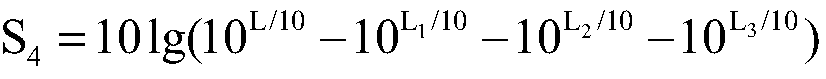

[0043] Aiming at the noise reduction analysis of the current vehicle interior noise and getting rid of the single method of judging the noise source only by experience, the present invention provides a noise source separation method for uniform speed noise, and calculates the noise sound pressure level by setting different test conditions. Separating powertrain noise, tire noise, wind noise, and road noise from noise sources can quickly and effectively optimize the NVH performance of the vehicle, reduce vehicle noise, and improve vehicle performance and comfort.

[0044] Such as figure 2 As shown, it is a flow chart of a noise source separation method for uniform velocity noise provided by the present invention...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap