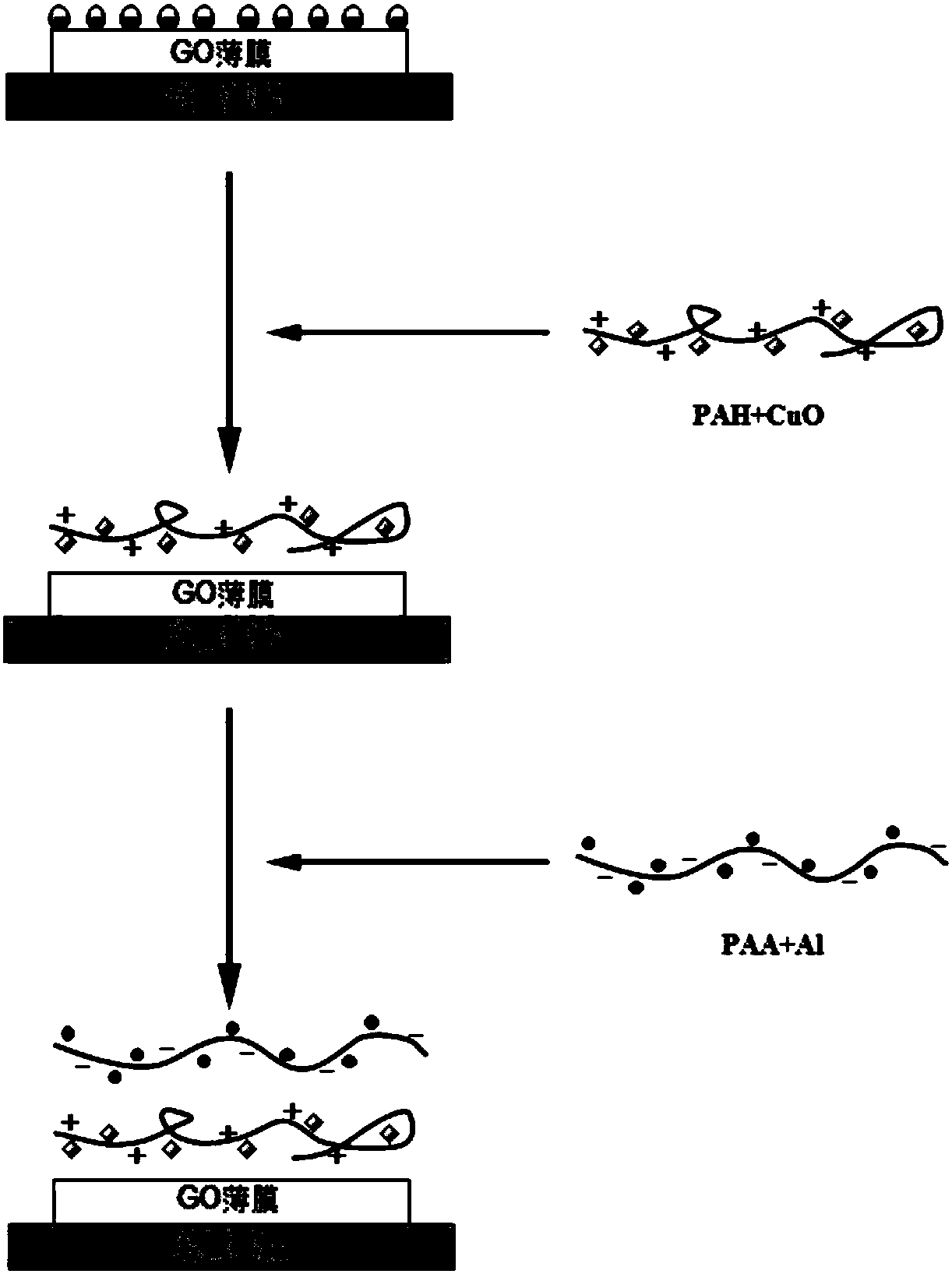

A kind of al-cuo/graphene oxide composite film and preparation method thereof

A graphene composite, graphene film technology, applied in nanotechnology, nanotechnology, coating and other directions for materials and surface science, can solve the propagation restraint of thermite reaction, slow energy release rate, limit thermite, etc. problems, to achieve the effect of improving the contact area and uniformity, reducing the initial ignition energy, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of Al-CuO / graphene oxide composite film, comprising the following steps:

[0027] (1) Surface pretreatment of copper substrate

[0028] a. Polishing: use sandpaper or a polishing machine to polish the copper sheet;

[0029] b. Degreasing: place the copper sheet in acetone for 10 minutes, ultrasonic power 1000W;

[0030] c. Pickling: place the copper sheet in a 20% hydrochloric acid solution for ultrasonic treatment for 5 minutes, and the ultrasonic power is 1000W;

[0031] (2) ultrasonically disperse the graphene oxide in the aqueous solution, the ultrasonic time is 1h, the ultrasonic power is 1000W, and it is configured into a 0.5mg / mL graphene oxide aqueous dispersion;

[0032] (3) Add the graphene oxide aqueous dispersion of step (2) into the electrophoretic deposition tank as the electrophoretic deposition solution, use stainless steel as the cathode pole piece, and place the copper sheet pretreated in step (1) as the anode pole piece in the e...

Embodiment 2

[0039] A preparation method of Al-CuO / graphene oxide composite film, comprising the following steps:

[0040] (1) Surface pretreatment of copper substrate

[0041] a. Polishing: use sandpaper or a polishing machine to polish the copper sheet;

[0042] b. Degreasing: place the copper sheet in ethanol for 10 minutes, ultrasonic power 1000W;

[0043] c. Pickling: Place the copper sheet in a 20% hydrochloric acid solution for ultrasonic treatment for 10 minutes, with an ultrasonic power of 500W;

[0044](2) Ultrasonically disperse the graphene oxide in the aqueous solution, the ultrasonic time is 2h, the ultrasonic power is 500W, and it is configured into a 1mg / mL graphene oxide aqueous dispersion;

[0045] (3) Add the graphene oxide aqueous dispersion of step (2) into the electrophoretic deposition tank as the electrophoretic deposition solution, use stainless steel as the cathode pole piece, and place the copper sheet pretreated in step (1) as the anode pole piece in the elect...

Embodiment 3

[0052] A preparation method of Al-CuO / graphene oxide composite film, comprising the following steps:

[0053] (1) Surface pretreatment of copper substrate

[0054] a. Polishing: use sandpaper or a polishing machine to polish the copper sheet;

[0055] b. Degreasing: Put the copper sheet in ethanol for 30 minutes and ultrasonically treat it with 300W ultrasonic power;

[0056] c. Pickling: place the copper sheet in a 20% hydrochloric acid solution for ultrasonic treatment for 5 minutes, and the ultrasonic power is 500W;

[0057] (2) Ultrasonically disperse the graphene oxide in the aqueous solution, the ultrasonic time is 3h, the ultrasonic power is 500W, and it is configured into a 2mg / mL graphene oxide aqueous dispersion;

[0058] (3) Add the graphene oxide aqueous dispersion of step (2) into the electrophoretic deposition tank as the electrophoretic deposition solution, use stainless steel as the cathode pole piece, and place the copper sheet pretreated in step (1) as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com