Rigid polypropylene composition for primerless painting

A technology of polypropylene composition and polypropylene homopolymer, which is applied in the application field of paint failure, and can solve problems such as high wear rate and lack of paint adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

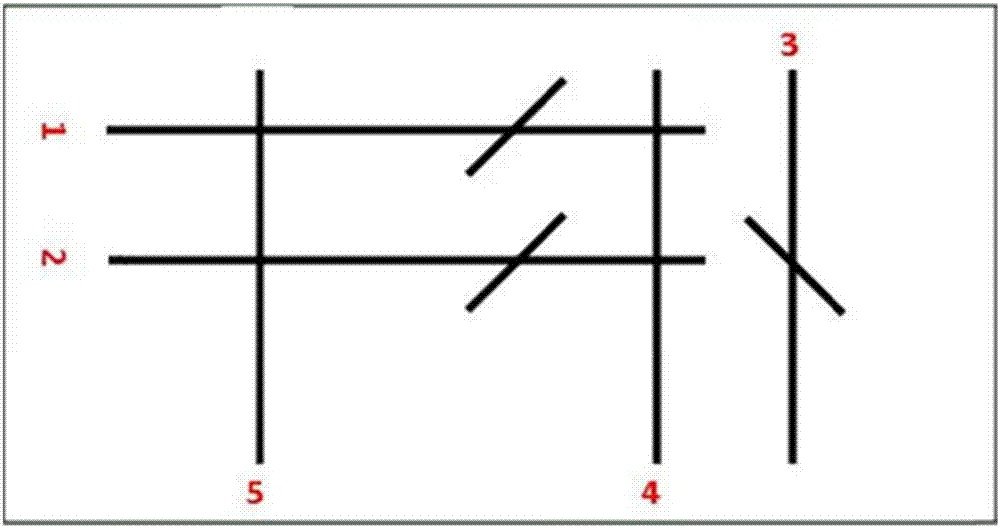

Image

Examples

preparation example Construction

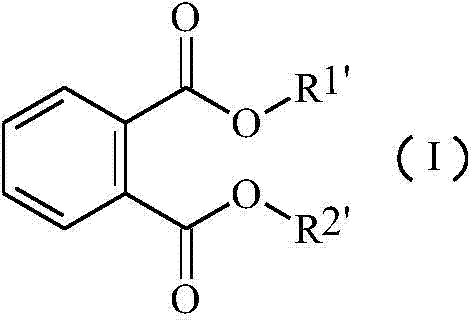

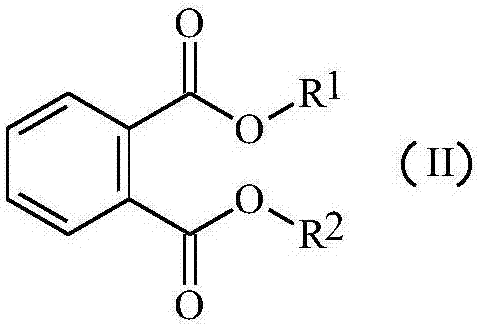

[0237] As regards the preparation of the polypropylene homopolymer (PP-H1 ) reference is made to the above description provided for the polypropylene matrix (M) of the heterophasic propylene copolymer (HPP), ie the polypropylene homopolymer (PP-H2).

[0238] Mineral filler (F)

[0239] In addition to the polymer component, the polymer composition according to the present invention is also contained in the range of 20.0 to 40.0 wt%, and preferably in the range of 25.0 to 35.0 wt%, based on the total weight of the polymer composition mineral filler (F). Another requirement of the present invention is that the mineral filler (F) is selected from the group consisting of talc, wollastonite, kaolin and mica.

[0240] In one embodiment of the invention, the mineral filler (F) is talc.

[0241]The average particle size d50 of the mineral filler (F) is preferably in the range of 0.5-20.0 μm, more preferably in the range of 0.5-15.0 μm, still more preferably in the range of 0.75-10.0 ...

Embodiment

[0287] A. Measurement method

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com